Two-layer module bracket and battery pack

A module and battery technology, applied in battery pack components, circuits, electrical components, etc., can solve problems such as restricting the development of power battery systems, difficult to control product size, affecting product performance, etc., to reduce physical consumption and save energy. Production time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

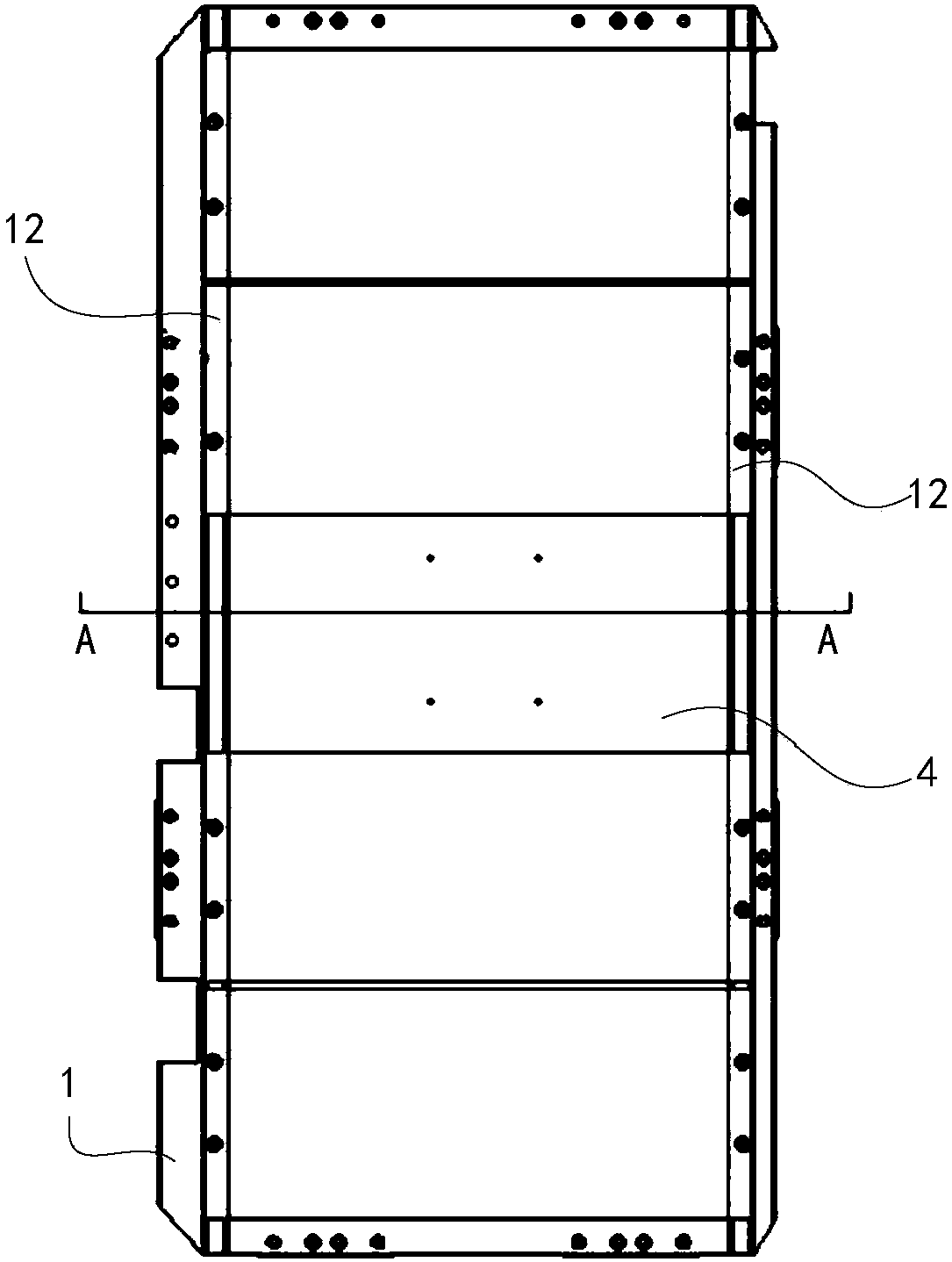

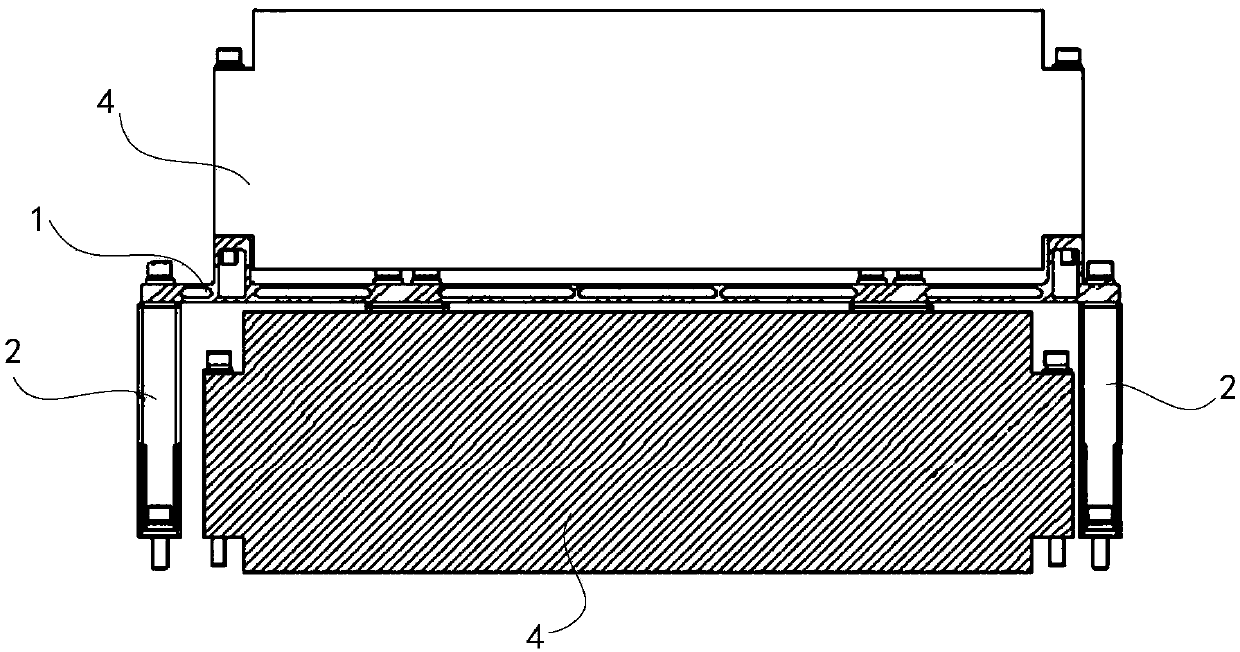

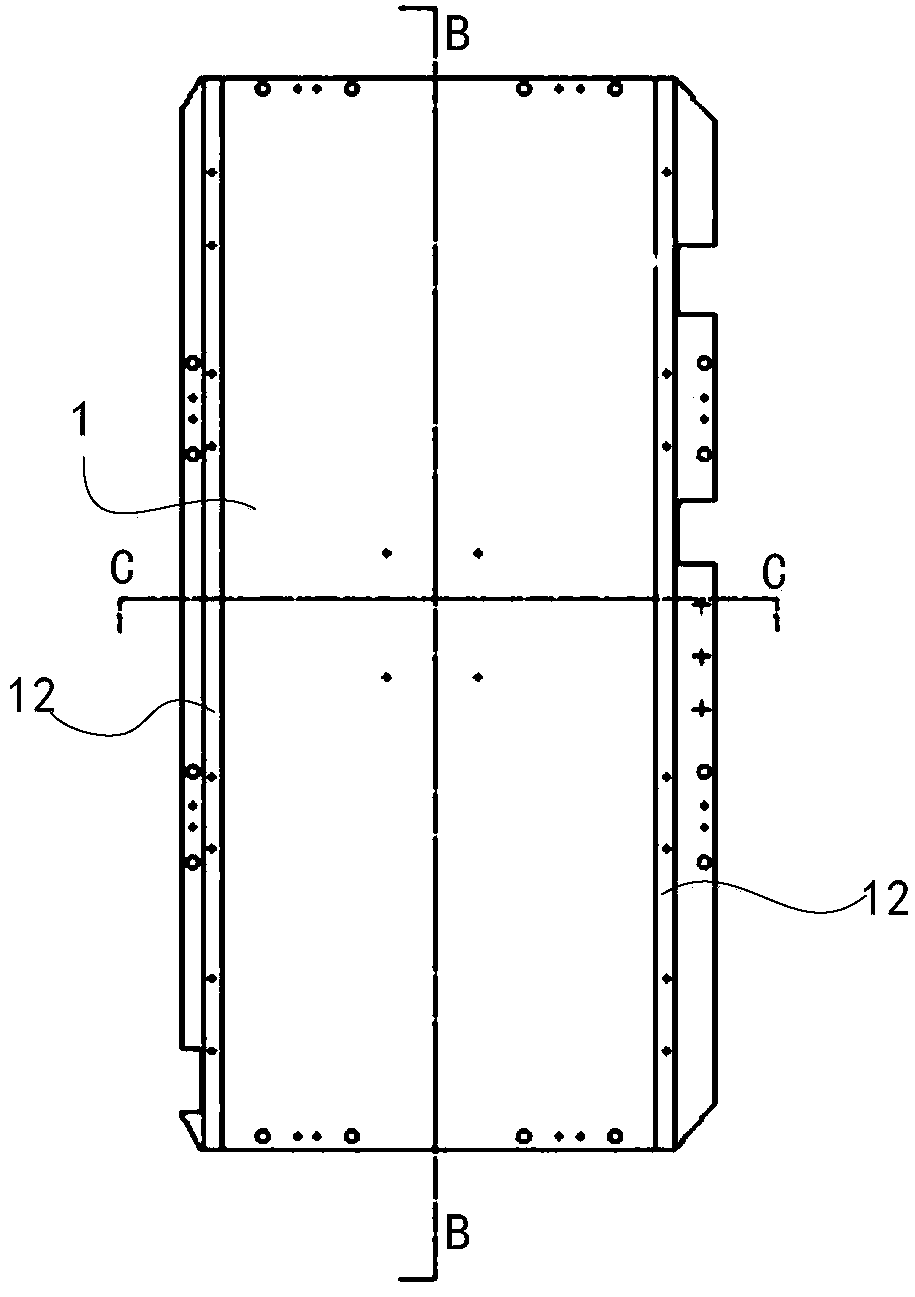

[0054] The battery pack of this embodiment includes a battery case 3, several battery modules 4, an electrical box 5, connectors 6 and the two-layer module support of the embodiment, and several battery modules 4 are installed on the inner wall of the bottom of the battery case 3 respectively. On and on the tray 1, the electrical box and connectors are installed in the battery box and connected to the battery module through a wire harness. In this embodiment, by installing a two-layer module bracket in the battery box, the weight of the whole module bracket is light, the cost of the mold is low, the processing and molding process is simple, and the structural strength is high; because the inside of the tray is hollow, it is relatively light, which can reduce the operator's work. Physical exertion improves production efficiency.

[0055] In describing the present invention, it should be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com