Method for producing CAF-resistant copper clad board based on non-directional fiber material

A technology of fiber materials and copper clad laminates, applied in electrical components, manufacturing printed circuit precursors, printed circuit manufacturing, etc., can solve problems such as failure and leakage PCB, and achieve the effect of improving CAF resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

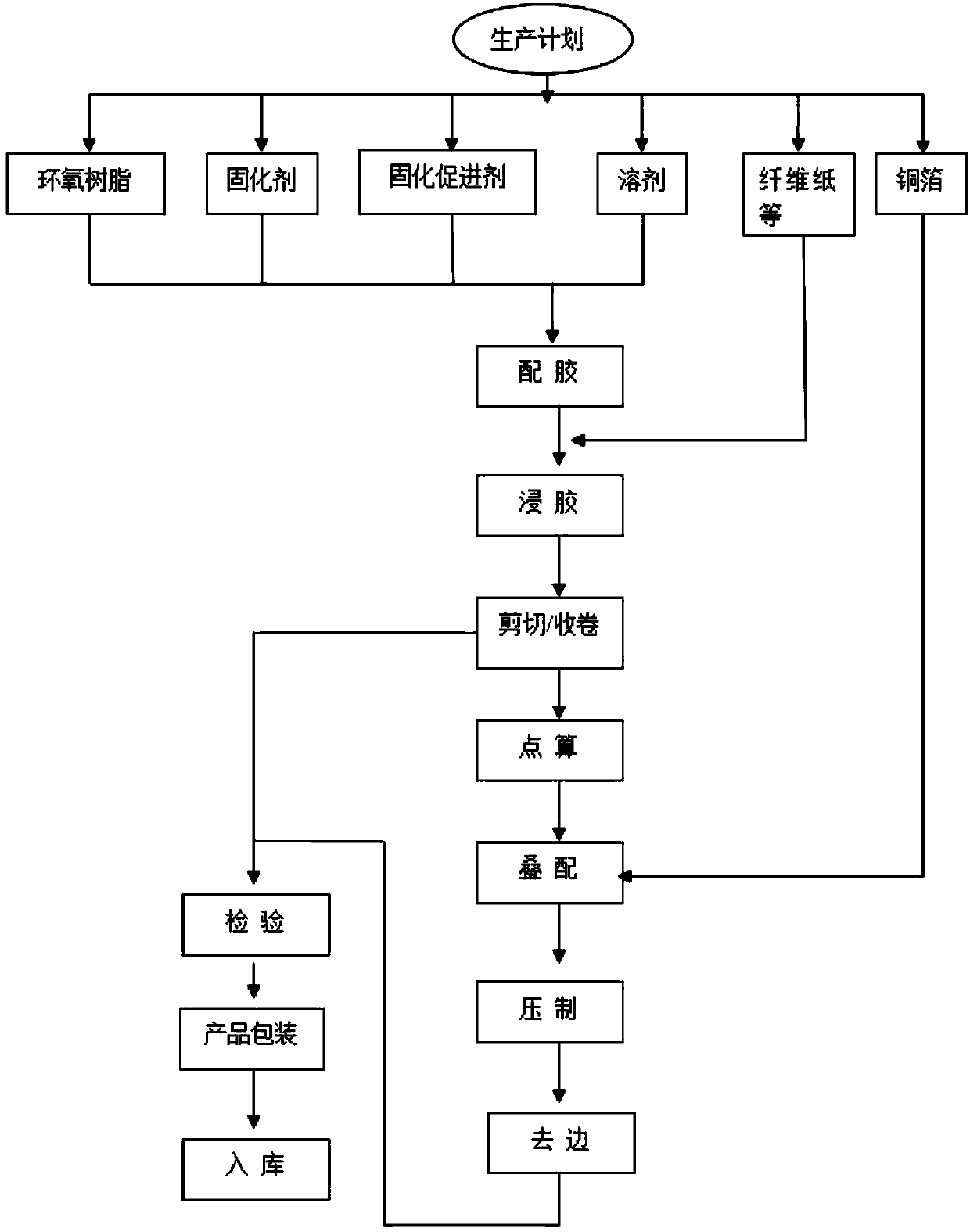

[0031] see Figure 1-2 Shown, the present invention is a kind of method for producing anti-CAF copper-clad laminate based on unoriented fiber material, comprises the steps:

[0032] Step 1, mixing epoxy resin, curing agent, curing accelerator and solvent to prepare resin liquid;

[0033] Step 2, impregnating non-oriented fiber paper, non-oriented fiber cloth or non-oriented fiber mat with the above resin solution, making it into a semi-cured state at a temperature of 145 ° C, and making a prepreg after drying;

[0034] Step 3, cutting the prepreg made above into a semi-finished prepreg of required size;

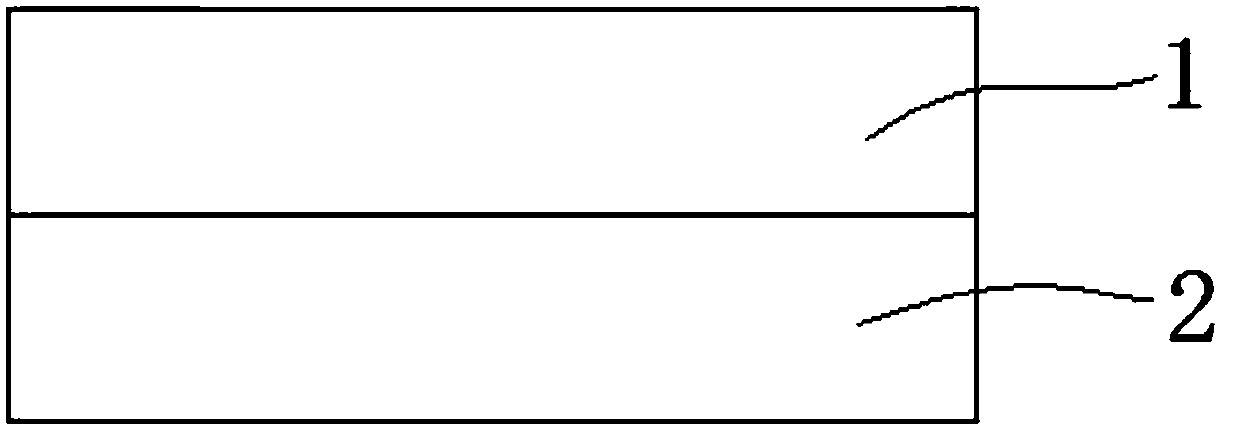

[0035] Step 4. According to the thickness requirement, superimpose 2 semi-finished prepregs to make fabric 2 of required thickness, and cover one side of fabric 2 with copper foil 1; at a temperature of 120°C and a pressure of 100kg / cm 2 And vacuum degree -60mmHg or less, thermoforming;

[0036] Step 5, use a cutter to cut off the leftover material of the hot-pressed coppe...

Embodiment 2

[0044] see figure 1 and 3 Shown, the present invention is a kind of method for producing anti-CAF copper-clad laminate based on unoriented fiber material, comprises the steps:

[0045] Step 1, mixing epoxy resin, curing agent, curing accelerator and solvent to prepare resin liquid;

[0046] Step 2, impregnating non-oriented fiber paper, non-oriented fiber cloth or non-oriented fiber mat with the above resin solution, making it into a semi-cured state at a temperature of 180 ° C, and making a prepreg after drying;

[0047] Step 3, cutting the prepreg made above into a semi-finished prepreg of required size;

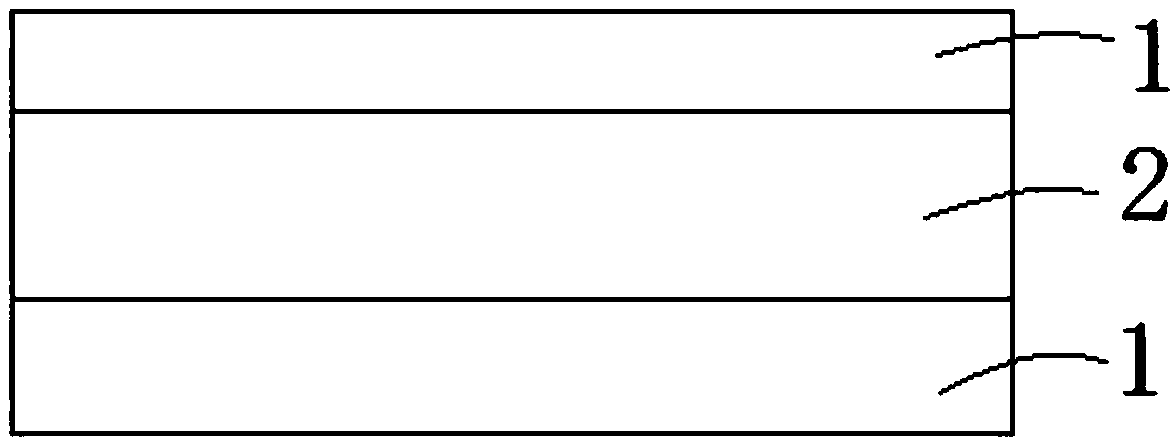

[0048] Step 4. According to the thickness requirement, superimpose 6 semi-finished prepregs to make fabric 2 of required thickness, and coat copper foil 1 on both sides of fabric 2; at a temperature of 180°C and a pressure of 60kg / cm 2 And vacuum degree -60mmHg or less, thermoforming;

[0049] Step 5, use a cutter to cut off the leftover material of the hot-pressed cop...

Embodiment 3

[0057] see figure 1 and 4 Shown, the present invention is a kind of method for producing anti-CAF copper-clad laminate based on unoriented fiber material, comprises the steps:

[0058] Step 1, mixing epoxy resin, curing agent, curing accelerator and solvent to prepare resin liquid;

[0059] Step 2, impregnating non-oriented fiber paper, non-oriented fiber cloth or non-oriented fiber felt with the above resin solution, making it into a semi-cured state at a temperature of 205 ° C, and making a prepreg after drying;

[0060] Step 3, cutting the prepreg made above into a semi-finished prepreg of required size;

[0061] Step 4. According to the thickness requirements, stack 9 semi-finished prepregs to make a fabric 2 of the required thickness. An insulating layer 3 is provided between two adjacent fabrics 2, and copper foil is coated on the outer surface of the two adjacent fabrics 2. 1; At a temperature of 85°C and a pressure of 15kg / cm 2 And vacuum degree -60mmHg or less, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com