Prepreg, laminated board and printed circuit board

A printed circuit board and prepreg technology, applied in the directions of printed circuits, circuit substrate materials, printed circuit components, etc., can solve the problem of insignificant ion migration resistance of the board, and achieve improved CAF resistance and high CAF resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

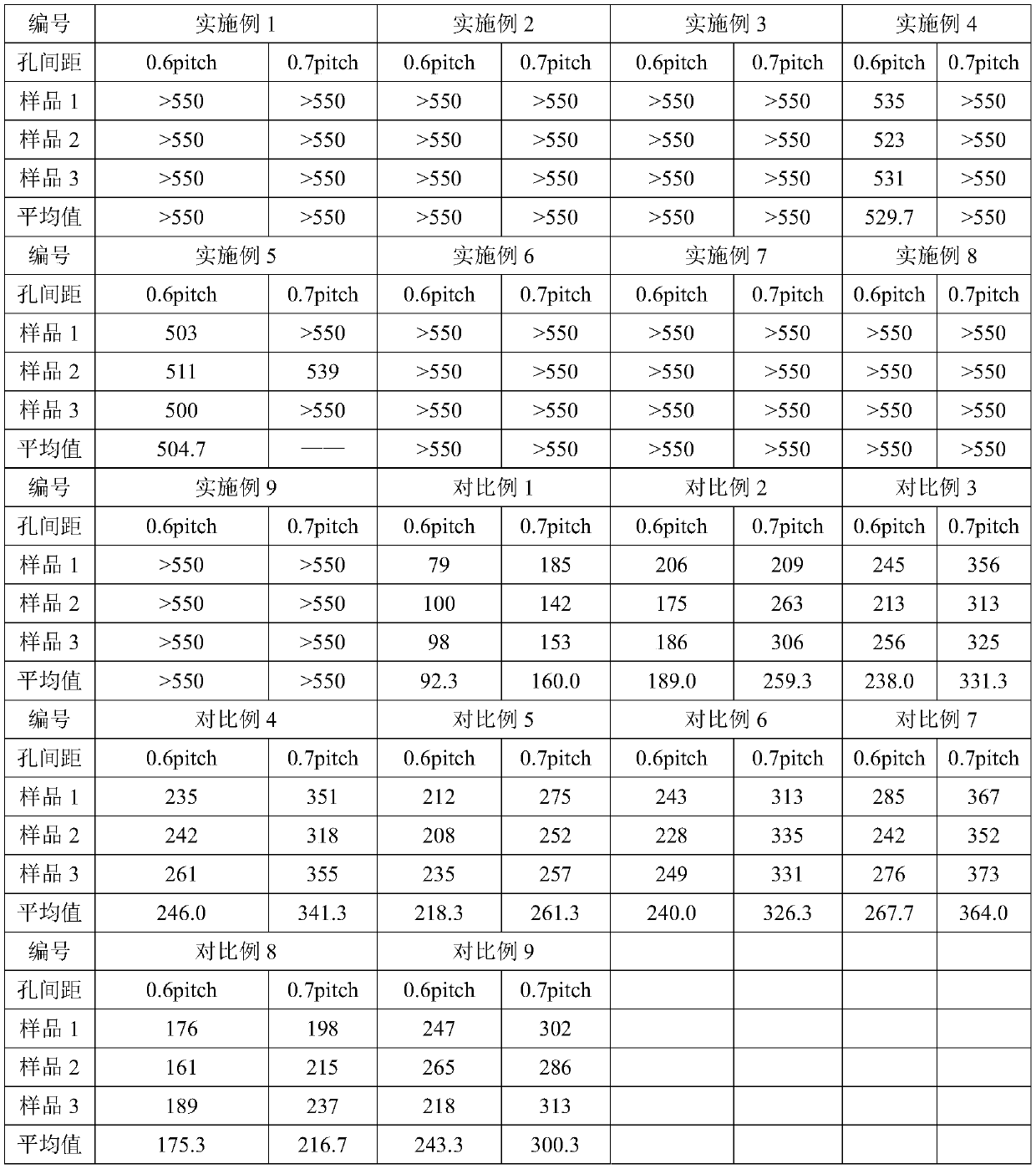

Embodiment 1

[0062] Multifunctional brominated epoxy resin XQ82937 (47.61wt%), phosphorus-containing phenolic resin KPH-L2005TMP (24.85wt%), four-functional epoxy resin EPON1031A70 (2.45wt%), imidazole accelerator 2E4MI (0.10wt%, 2E4MI produced by Japan Shikoku Chemical Industry) and silicon micropowder DS1032A (25wt%) are dissolved in propylene glycol methyl ether solvent, mechanically stirred and dispersed to prepare a glue solution with a solid content of 65wt%, and then use the glue solution to infiltrate the ion-scavenging agent IXEPLAS-A2 package Covered 7628 type glass fiber cloth (IXEPLAS-A2 accounted for 0.01wt% by weight of glass fiber cloth), and dried to obtain prepreg. Eight sheets of the prepreg were stacked between two sheets of copper foil and hot-pressed in a vacuum press to prepare a laminate. The laminates were prepared into test samples according to the requirements of the determination and evaluation methods, and the test results are shown in Table 1.

Embodiment 2

[0064] Multifunctional brominated epoxy resin XQ82937 (47.61wt%), phosphorus-containing phenolic resin KPH-L2005TMP (24.85wt%), four-functional epoxy resin EPON1031A70 (2.45wt%), imidazole accelerator 2E4MI (0.10wt%, 2E4MI produced by Japan Shikoku Chemical Industry) and silicon micropowder DS1032A (25wt%) are dissolved in propylene glycol methyl ether solvent, mechanically stirred and dispersed to prepare a glue solution with a solid content of 65wt%, and then use the glue solution to infiltrate the ion-scavenging agent IXEPLAS-A2 package Covered 7628 type glass fiber cloth (IXEPLAS-A2 accounted for 2wt% by weight of glass fiber cloth), and dried to obtain prepreg. Eight sheets of the prepreg were stacked between two sheets of copper foil and hot-pressed in a vacuum press to prepare a laminate. The laminates were prepared into test samples according to the requirements of the determination and evaluation methods, and the test results are shown in Table 1.

Embodiment 3

[0066] Multifunctional brominated epoxy resin XQ82937 (47.61wt%), phosphorous phenolic resin KPH-L2005TMP (24.85wt%), four-functional epoxy resin EPON1031A70 (2.45wt%), imidazole accelerator 2E4MI (0.10wt%) Dissolve silica powder DS1032A (25wt%) in propylene glycol methyl ether solvent, mechanically stir and disperse to prepare a glue solution with a solid content of 65wt%, and then use the glue solution to infiltrate the 7628-type glass fiber coated with ion trapping agent IXEPLAS-A2 Cloth (IXEPLAS-A2 accounted for 5wt% by weight of the glass fiber cloth) was dried to obtain a prepreg. Eight sheets of the prepreg were stacked between two sheets of copper foil and hot-pressed in a vacuum press to prepare a laminate. The laminates were prepared into test samples according to the requirements of the determination and evaluation methods, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com