High-reliability halogen-free copper-clad plate for IC packaging and preparation method thereof

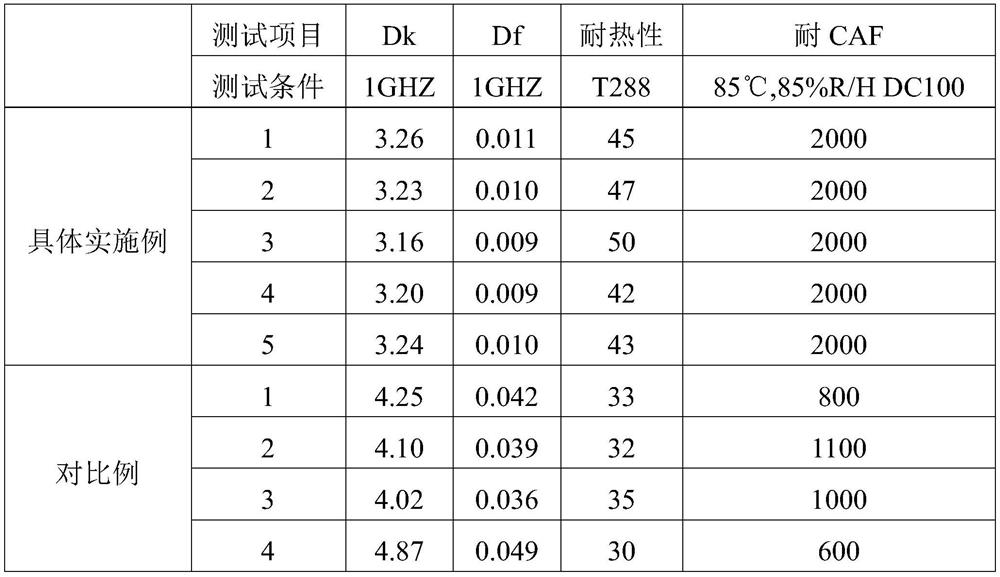

A copper-clad laminate and reliability technology, applied in 5G copper-clad laminate and its production field, can solve the problems of reduced insulation resistance between leads, electromagnetic waves cannot be shielded, poor moisture resistance, etc., achieve low dielectric constant, improve CAF resistance performance , Low hygroscopicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The above-mentioned resin glue is used to prepare the copper clad laminate, and the preparation method mainly includes the following steps:

[0061] S1, after weighing each component according to the composition of the above-mentioned resin glue, stir at 30-40°C for 4-6 hours;

[0062] S2, coating the resin glue solution prepared in step S1 on both sides of the glass fiber cloth, drying at 200-250° C. for 2-4 minutes, and the prepared glass fiber cloth impregnated sheet is a prepreg ;

[0063] S3, according to the required thickness and shape of the final copper-clad laminate, take 1-8 sheets of the prepreg prepared in step S2 and stack them together and then cut them, and finally cover both sides with a layer of copper foil as the top copper foil After layering and bottom copper foil layering, hot press at -700~-730mmHg, 200~220°C for 180~200min, and cool naturally to room temperature to obtain the desired copper clad laminate.

preparation specific Embodiment 1

[0065] S1, after weighing each component according to the composition of resin glue A, stir at 30°C for 4 hours;

[0066] S2, coating the resin glue solution A prepared in step S1 on both sides of the glass fiber cloth, drying at 200° C. for 2 minutes, and the prepared glass fiber cloth impregnated tablet is a prepreg;

[0067] S3, according to the required thickness and shape structure of the final copper-clad laminate, take 6 pieces of the prepreg prepared in step S2 and stack them together and then cut them, and finally cover both sides with a layer of 25 μm thick copper foil as the top copper foil After the layer and the bottom copper foil layer, hot press at -700mmHg, 200°C for 180min, and naturally cool to room temperature to obtain the required copper clad laminate.

preparation specific Embodiment 2

[0069] S1, after weighing each component according to the composition of resin glue B, stir at 35°C for 5 hours;

[0070] S2, coating the resin glue B prepared in step S1 on both sides of the glass fiber cloth, drying at 210° C. for 3 minutes, and the prepared glass fiber cloth impregnated tablet is a prepreg;

[0071] S3, according to the required thickness and shape structure of the final copper-clad laminate, take 6 pieces of the prepreg prepared in step S2 and stack them together and then cut them, and finally cover both sides with a layer of 25 μm thick copper foil as the top copper foil After the layer and the bottom copper foil layer, hot press at -710mmHg, 210°C for 190min, and naturally cool to room temperature to obtain the required copper clad laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com