Processing equipment for high frequency transformers

A technology for high-frequency transformers and processing equipment, applied in the direction of transformers/inductor coils/windings/connections, chemical instruments and methods, cleaning methods using gas flow, etc., can solve the problem of damaged pins and transformer soldering, manual alignment Good, low efficiency of manual straightening, etc., to achieve the effect of reducing manual operation, reducing the defective rate of transformers, and facilitating straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed explanation through specific implementation mode below:

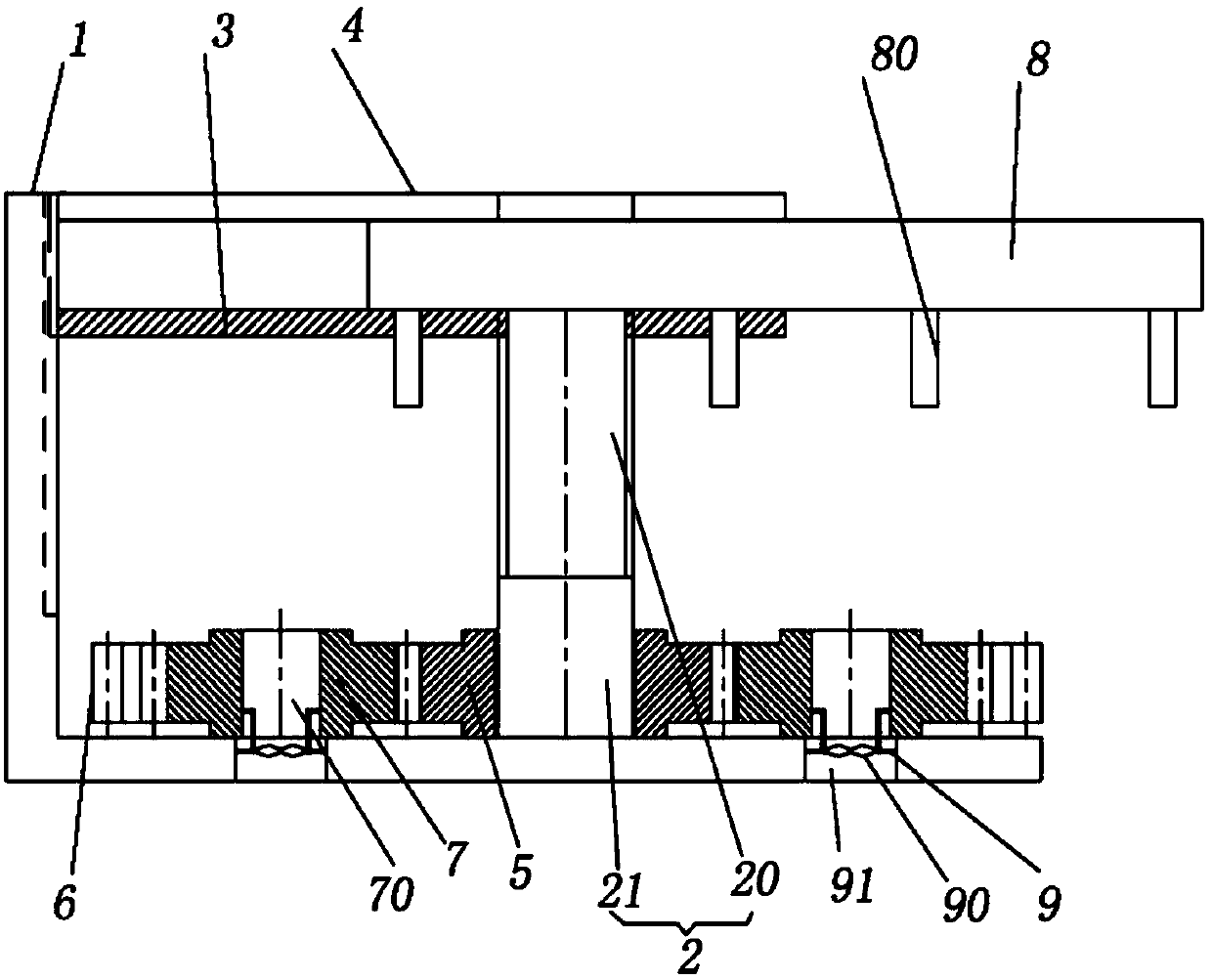

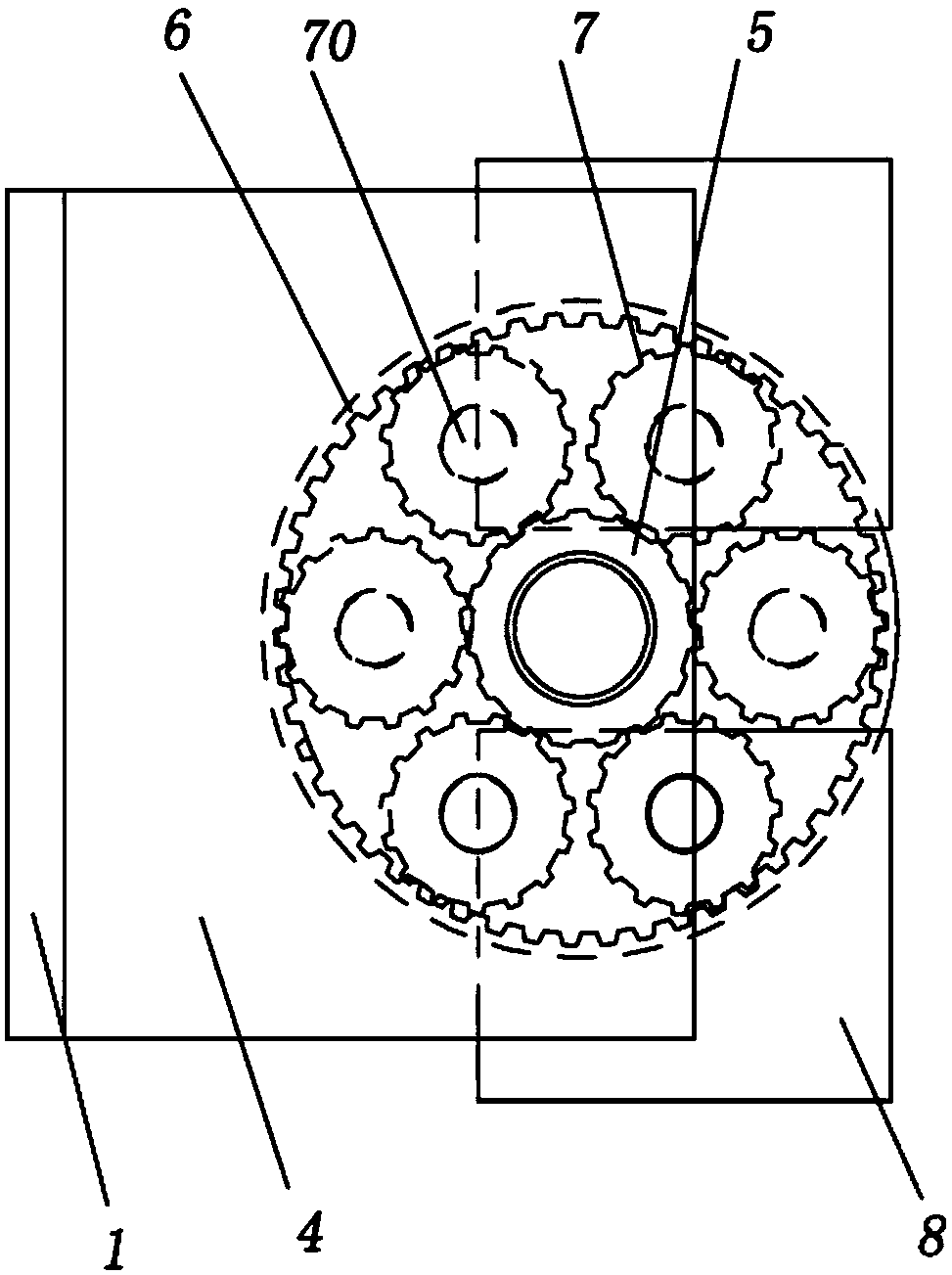

[0025] The reference signs in the drawings of the description include: frame 1, rotating shaft 2, threaded section 20, smooth surface section 21, threaded cover 3, buckle plate 4, transmission hub 5, support hub 6, rotating hub 7, alignment hole 70 , Transformer body 8, pin 80, support frame 9, negative pressure blade 90, dust removal hole 91.

[0026] The embodiment is basically as attached figure 1 Shown: Processing equipment for high-frequency transformers, including frame 1, motor, lifting mechanism and straightening mechanism.

[0027] Frame 1 is " L " shape, is provided with chute in its vertical part.

[0028] The lifting mechanism includes a rotating shaft 2 and a support cover for fixing the transformer body 8 . The rotating shaft 2 includes a threaded section 20 at the top and a smooth section 21 at the bottom, and the output shaft of the motor is coaxially connected with the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com