Forging method of high uniform Ti632211 titanium alloy sheet

A technology of ti632211 and titanium alloy, which is applied in the forging field of high-uniform Ti632211 titanium alloy plate, can solve the problem of Ti632211 titanium alloy plate with less forging and other problems, and achieve the effect of uniform structure and excellent structure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Blanking: Ti632211 titanium alloy ingots are subjected to upsetting and pulling at 1150°C, the deformation is controlled at 45%, the coarse as-cast structure is fully broken, and air-cooled after forging;

[0018] 2) Intermediate forging: upsetting 3 times at 80°C above the phase transition point of the Ti632211 titanium alloy, and controlling the deformation of each fire at 40%, and then upsetting in the form of flat square upsetting at 40°C below the phase transition point of the Ti632211 titanium alloy Pulling 3 times, the deformation of each fire is controlled at 30%, in order to refine the grain, water cooling is used after each fire forging;

[0019] 3) Finished forging: at 40°C below the β-transition point of the Ti632211 titanium alloy, elongate with a deformation of 15% to produce a highly uniform Ti632211 titanium alloy plate.

Embodiment 2

[0021] 1) Blanking: Ti632211 titanium alloy ingots are subjected to upsetting and pulling at 1200°C, the deformation is controlled at 50%, the coarse as-cast structure is fully broken, and air-cooled after forging;

[0022] 2) Intermediate forging: Upsetting and drawing 4 times at 100°C above the phase transition point of Ti632211 titanium alloy, the amount of deformation per fire is controlled at 50%, and then upsetting in the form of flat square upsetting at 50°C below the phase transition point of Ti632211 titanium alloy Pulling 2 times, the deformation of each fire is controlled at 30%, in order to refine the grain, water cooling is used after each fire forging;

[0023] 3) Finished forging: 50°C below the β-transition point of the Ti632211 titanium alloy, elongated with a deformation of 20% to produce a highly uniform Ti632211 titanium alloy plate.

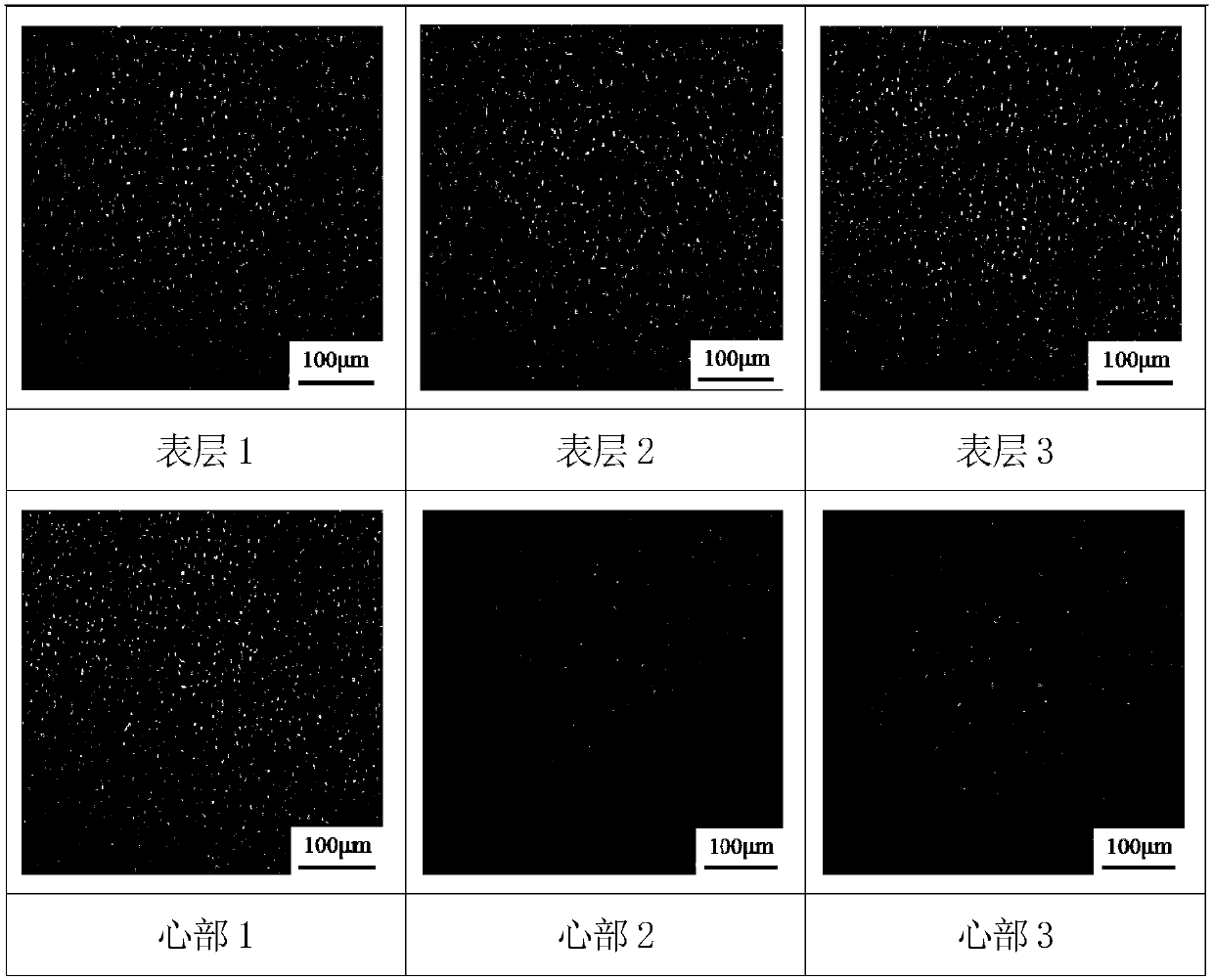

[0024] Depend on Figure 1 to Figure 3 It can be seen that the microstructure of the H=110mm thick plate is basically comp...

Embodiment 3

[0026] 1) Blanking: Ti632211 titanium alloy ingots are subjected to upsetting and pulling at 1180°C, the deformation is controlled at 40%, the coarse as-cast structure is fully broken, and air-cooled after forging;

[0027] 2) Intermediate forging: Upsetting and drawing 4 times at 50°C above the phase transition point of Ti632211 titanium alloy, the deformation of each fire is controlled at 45%, and then upsetting in the form of flat square upsetting at 20°C below the phase transition point of Ti632211 titanium alloy Pulling 4 times, the deformation of each fire is controlled at 25%, in order to refine the grain, water cooling is used after each fire forging;

[0028] 3) Finished forging: at 60°C below the β-transition point of the Ti632211 titanium alloy, stretch it with a deformation of 10% to make a highly uniform Ti632211 titanium alloy plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com