Thin film conveying deviation correction structure and control method

A control method and film technology, which is applied in thin material processing, winding strips, transportation and packaging, etc., can solve problems such as equipment failure downtime, complex deviation correction process, large film position deviation, etc., to achieve accurate transmission and deviation correction, and improve The effect of product quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

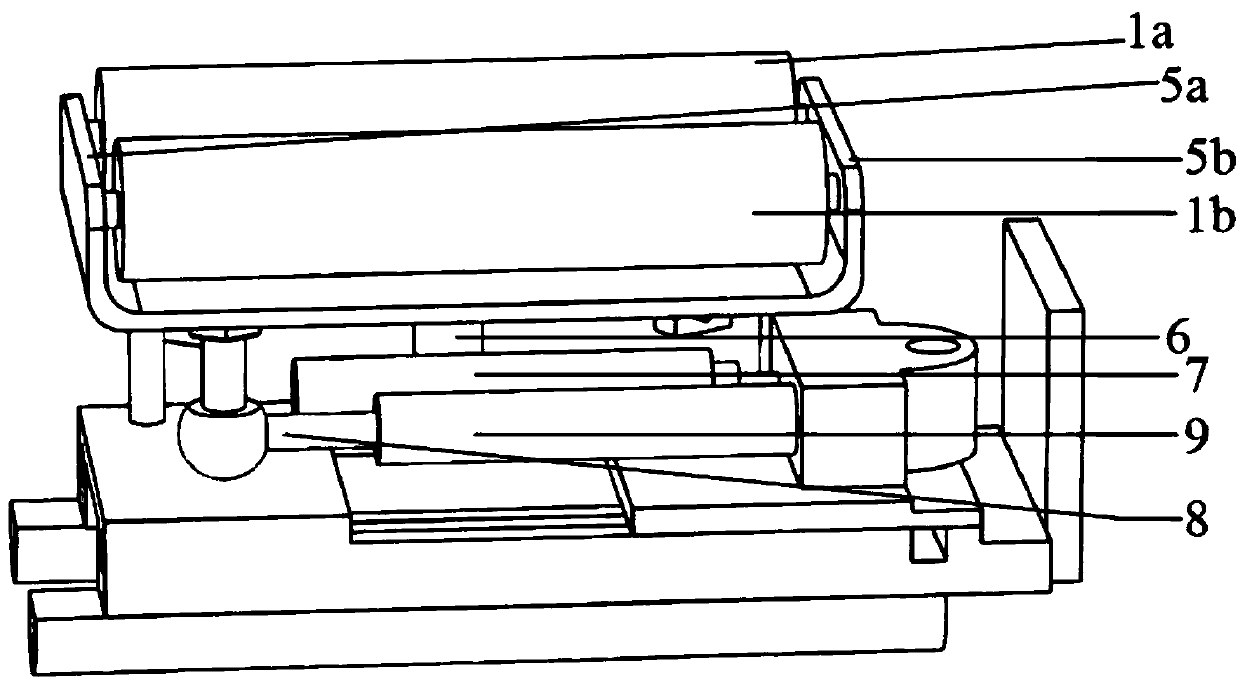

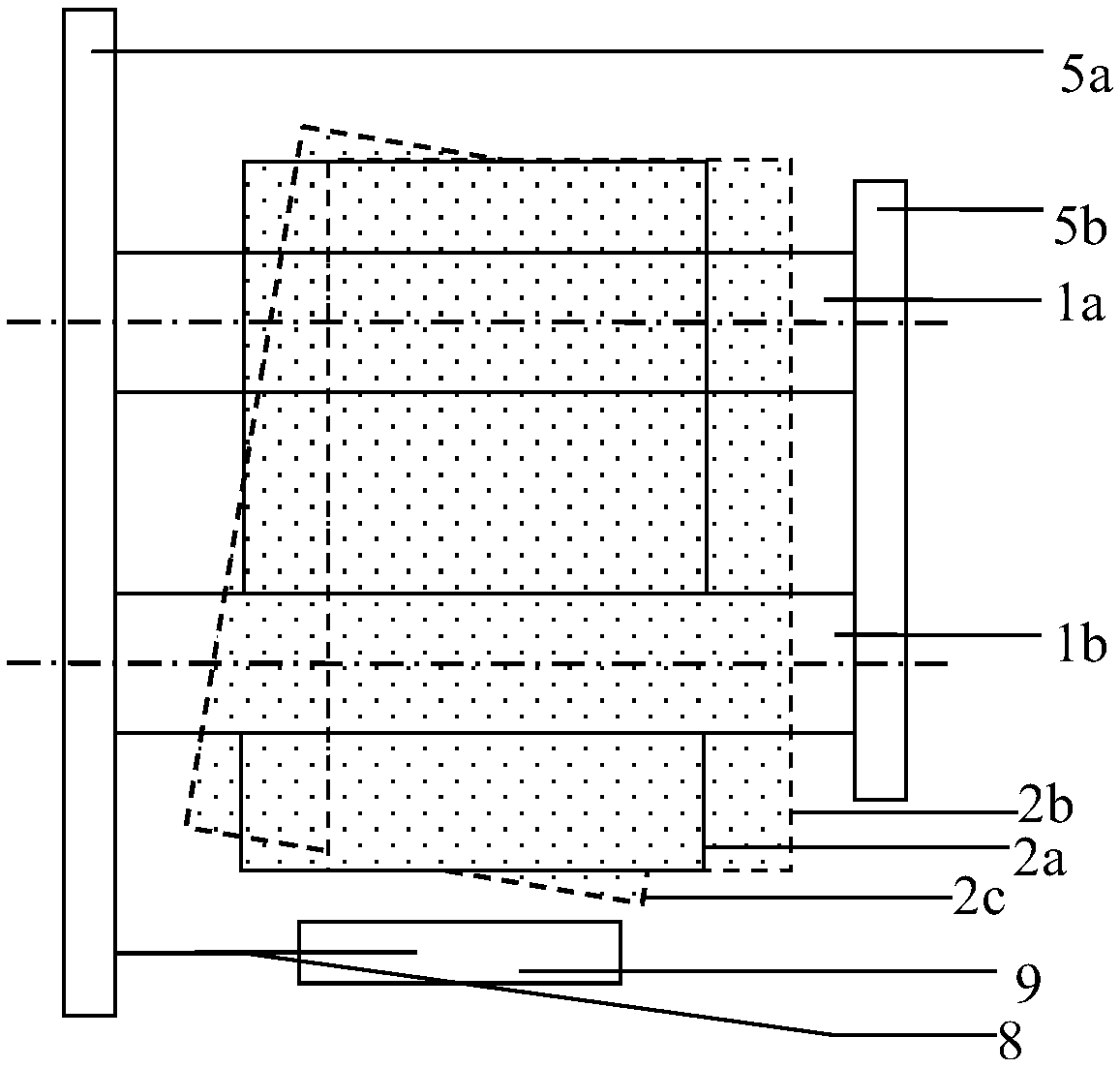

[0028] As shown in the figure, the correcting roller mount 5a and the correcting roller mount 5b are used to install two correcting rollers 1a, 1b and the telescopic rod 8 in parallel; Distance: One end of the telescopic rod 8 is connected to the deviation-correcting roller mounting seat 5a, and one end is installed in the sleeve 9, and the entire deviation-correcting roller mounting seat can move left and right around the rotating shaft 6 of the deviation-correcting roller mounting seat.

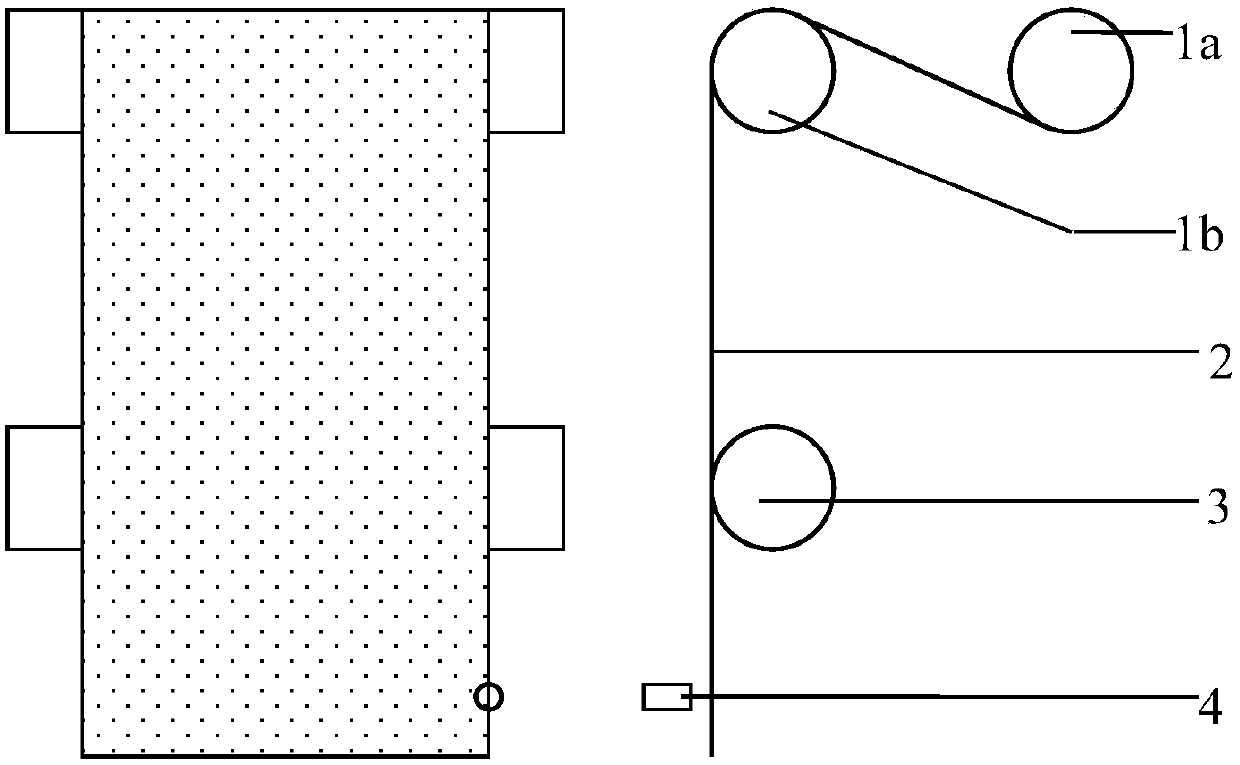

[0029] Such as figure 1 As shown, the film 2 is conveyed through the correction roller 1a, the correction roller 1b and the conveying roller 3, and the film conveying position detector 4 detects the conveying position of the film 2 on the conveying roller 3 in real time.

[0030] When the film conveying position detector 4 detects that the position of the film on the conveying roller 1 deviates, as image 3 , the film shifts to the right from the given transfer position 2a to 2b, the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com