Method for reducing bipolymer impurities in losartan

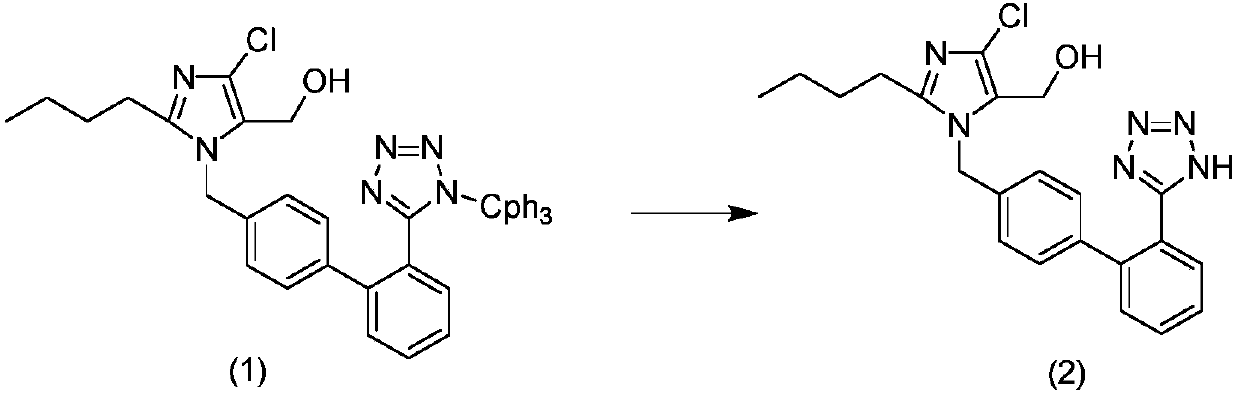

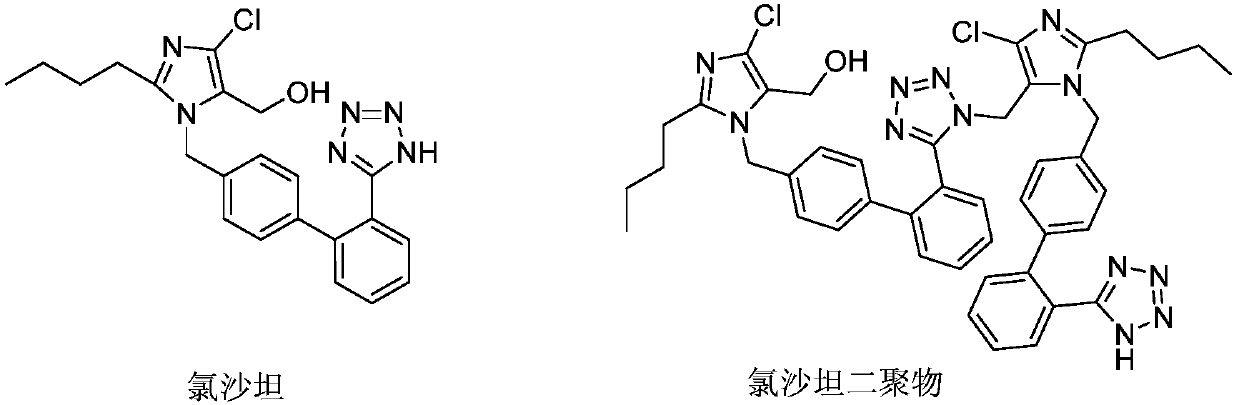

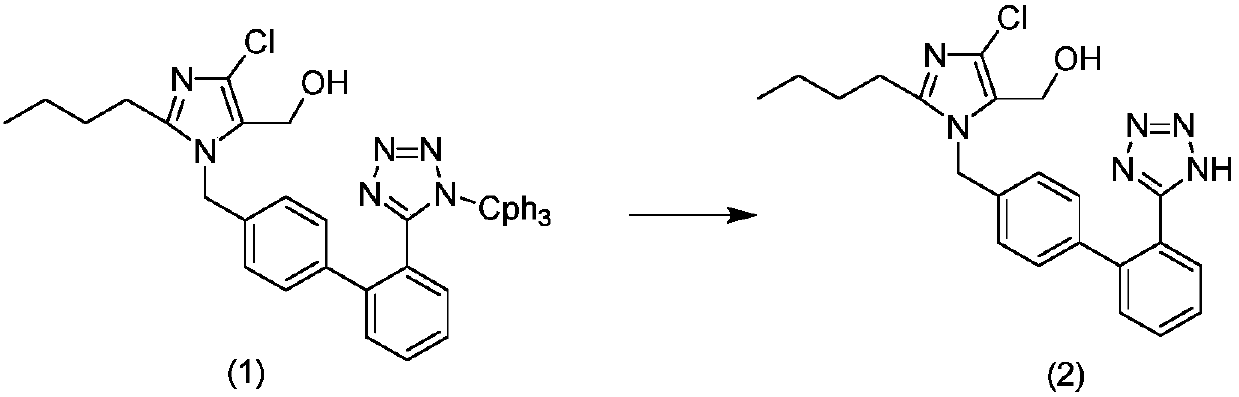

A technology for losartan dimer and losartan condensate, which is applied in the field of medicine and chemical industry, can solve the problems of lack of competitiveness and large loss, and achieves the effects of low cost, simple operation and high product conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 30g of losartan condensate into the three-neck flask, add 100ml of tetrahydrofuran; control the temperature at 10-20°C, use 4mol / L hydrochloric acid to adjust the pH of the system to 2, keep it warm at 28°C, stir for 12 hours, cool down to 10°C, and use Adjust the pH of the NaOH solution to 12-13, control the temperature at 30-50°C, distill THF to dryness under reduced pressure, add 100mL of water, filter, control the temperature of the filtrate at 10-20°C, adjust the acid to pH 4 with 4mol / L hydrochloric acid, Stir and crystallize at room temperature for 3 hours, filter with suction, and dry to obtain losartan with a yield of 96% and dimer impurities of 0.2%.

Embodiment 2

[0023] Add 30g of losartan condensate into the three-necked flask, add 100ml of tetrahydrofuran; control the temperature at 10-20°C, use 4mol / L hydrochloric acid to adjust the pH of the system to 2, keep warm at 25°C, stir for 12 hours, cool down to 10°C, and use Adjust the pH of the NaOH solution to 12-13, control the temperature at 30-50°C, distill THF to dryness under reduced pressure, add 100mL of water, filter, control the temperature of the filtrate at 10-20°C, adjust the acid to pH 4 with 4mol / L hydrochloric acid, Stir and crystallize at room temperature for 3 hours, filter with suction, and dry to obtain losartan with a yield of 96% and dimer impurities of 0.15%.

Embodiment 3

[0025] Add 30g of losartan condensate into the three-neck flask, add 100ml of tetrahydrofuran; control the temperature at 10-20°C, use 4mol / L hydrochloric acid to adjust the pH of the system to 2, keep warm at 20°C, stir for 12 hours, cool down to 10°C, and use Adjust the pH of the NaOH solution to 12-13, control the temperature at 30-50°C, distill THF to dryness under reduced pressure, add 100mL of water, filter, control the temperature of the filtrate at 10-20°C, adjust the acid to pH 4 with 4mol / L hydrochloric acid, Stir and crystallize at room temperature for 3 hours, filter with suction, and dry to obtain losartan with a yield of 95% and a dimer impurity of 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com