Underwater epoxy resin grouting material

A technology of epoxy resin grouting and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problem of strength reduction and achieve high mechanical strength and excellent underwater bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

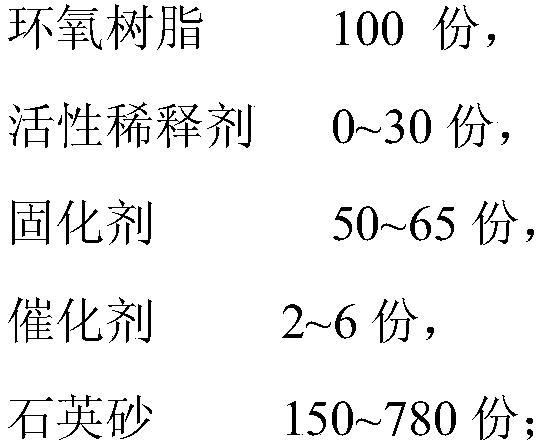

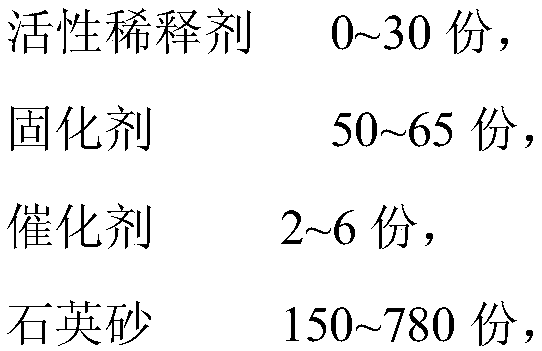

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0023] The tests of the compressive strength and bonding pull-out strength of each embodiment and comparative example were carried out according to D / L 5193-2004. The pouring and curing of the specimens were carried out under water at 20°C.

[0024] The formula ratio and performance data of each embodiment and comparative example are as shown in table 1 and table 2, wherein the curing agent used in comparative example 5 and comparative example 6 is the common 593 curing agent in this area (purchased from Changzhou Shanfeng Chemical Co., Ltd. ), does not contain imidazoline structure. The curing agent used in Comparative Examples 7 and 8 is a common ketimine curing agent in the art (purchased from Shandong Deyuan Epoxy Technology Co., L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com