Tapping oil and preparation method thereof

A technology of lard and rapeseed oil, which is applied in the field of tapping oil, can solve the problems of poor extreme pressure performance, short tapping life, and no high load-bearing performance, and achieve the effect of increasing the strength of the oil film and improving the boundary lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The invention provides a kind of preparation method of tapping oil, comprising:

[0056] A) mixing paraffinic base oil, refined lard, chlorinated paraffin, rapeseed oil, sulfurized olefin, sulfurized fatty acid ester and calcium sulfonate to obtain a mixture;

[0057] B) The mixture is heated and stirred to obtain tapping oil.

[0058] The preparation method of the tapping oil provided by the invention firstly mixes paraffin base oil, refined lard, chlorinated paraffin, rapeseed oil, sulfurized olefin, sulfurized fatty acid ester and calcium sulfonate to obtain a mixture.

[0059] The above-mentioned reaction of the present invention is preferably carried out in a reactor, and the present invention does not limit the reactor, as long as those skilled in the art are familiar with it.

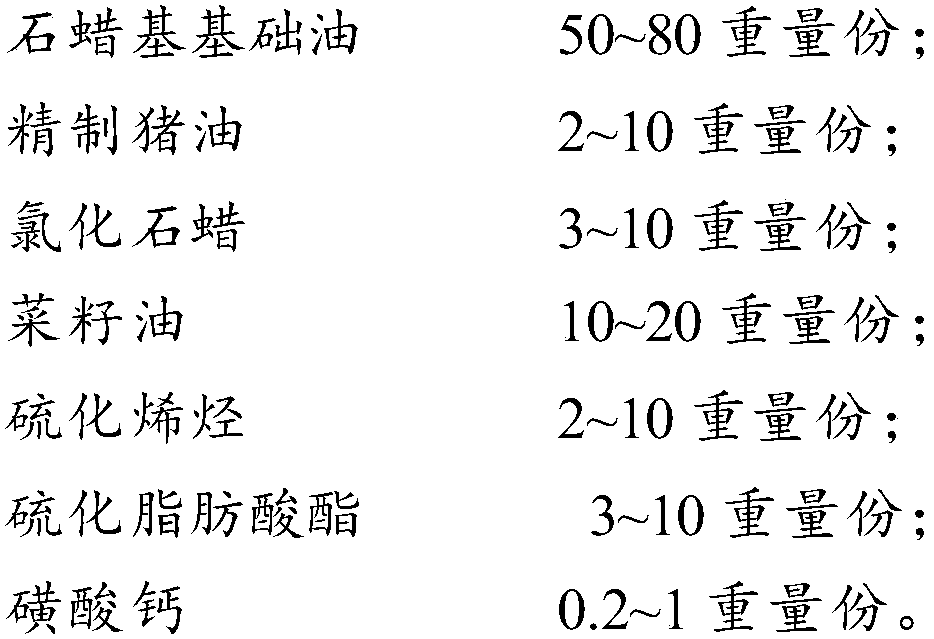

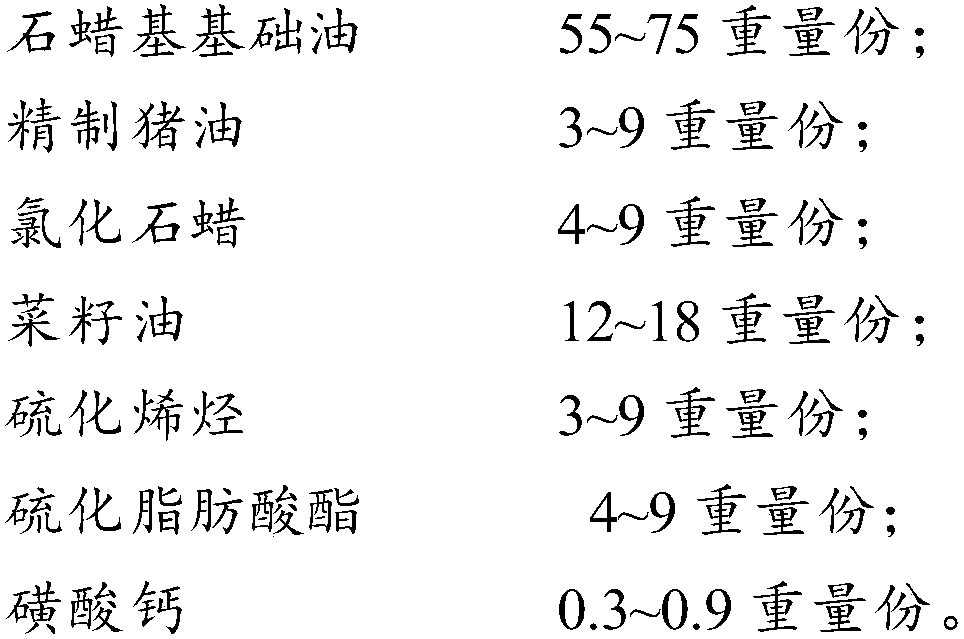

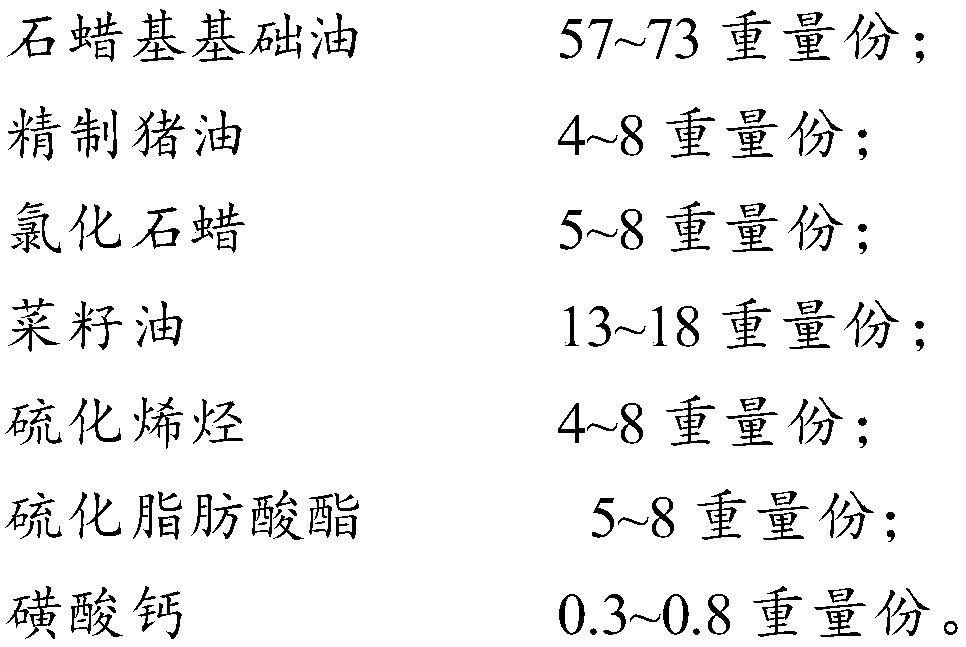

[0060] Wherein, the weight ratio of the paraffin-based base oil, refined lard, chlorinated paraffin, rapeseed oil, sulfurized olefin, sulfurized fatty acid ester and calcium sulfonate is ...

Embodiment 1

[0067]

[0068] The kinematic viscosity of paraffinic base oil at 40°C is preferably 32-100mm 2 / s.

[0069] Process:

[0070] The above raw materials are added to the production kettle in turn; the temperature is raised to 50-60°C, and stirred for 50 minutes until the product is uniform and transparent. The four-ball data of the product is: PB: 696N; PD: 3090N.

Embodiment 2

[0072]

[0073]

[0074] The kinematic viscosity of paraffinic base oil at 40°C is preferably 32-100mm 2 / s.

[0075] Process:

[0076] The above raw materials are added to the production kettle in turn; the temperature is raised to 50-60°C, and stirred for 50 minutes until the product is uniform and transparent. The four-ball data of the product is: PB: 745N; PD: 3920N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com