Stamping and drawing oil and preparation method thereof

A technology of stamping stretching and vegetable oil, applied in the field of stretching oil, which can solve the problems of high extreme pressure performance and cooling performance, which cannot be satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The invention provides a kind of preparation method of stamping drawing oil, comprising:

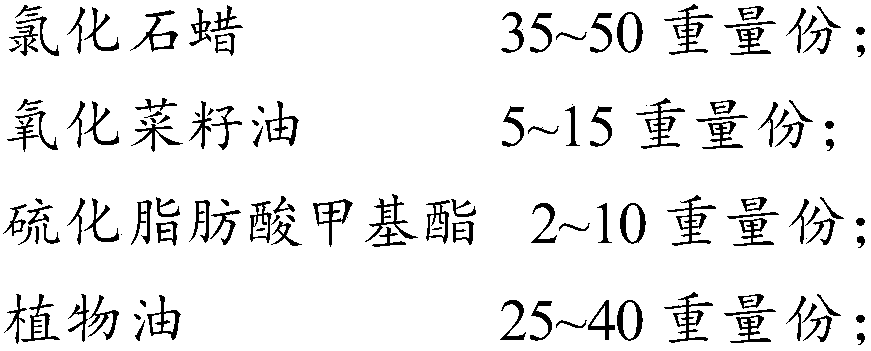

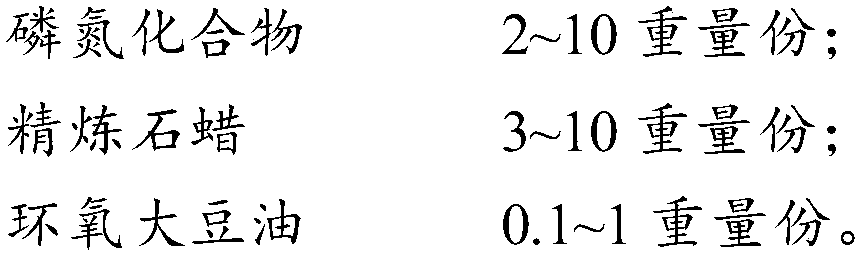

[0061] A) mixing chlorinated paraffin, oxidized rapeseed oil, sulfurized fatty acid methyl ester, vegetable oil, phosphorus nitrogen compound, refined paraffin and epoxidized soybean oil to obtain a mixture;

[0062] B) Heating and stirring the mixture to obtain stamping oil.

[0063] The preparation method of the stamping drawing oil provided by the invention firstly mixes chlorinated paraffin, oxidized rapeseed oil, sulfurized fatty acid methyl ester, vegetable oil, phosphorus nitrogen compound, refined paraffin and epoxidized soybean oil to obtain a mixture.

[0064] Wherein, the refined paraffin is fully refined paraffin, and the refined paraffin is preferably pulverized; the pulverized particle diameter is less than or equal to 1cm

[0065] The above-mentioned reaction of the present invention is preferably carried out in a reactor, and the present invention does not limit t...

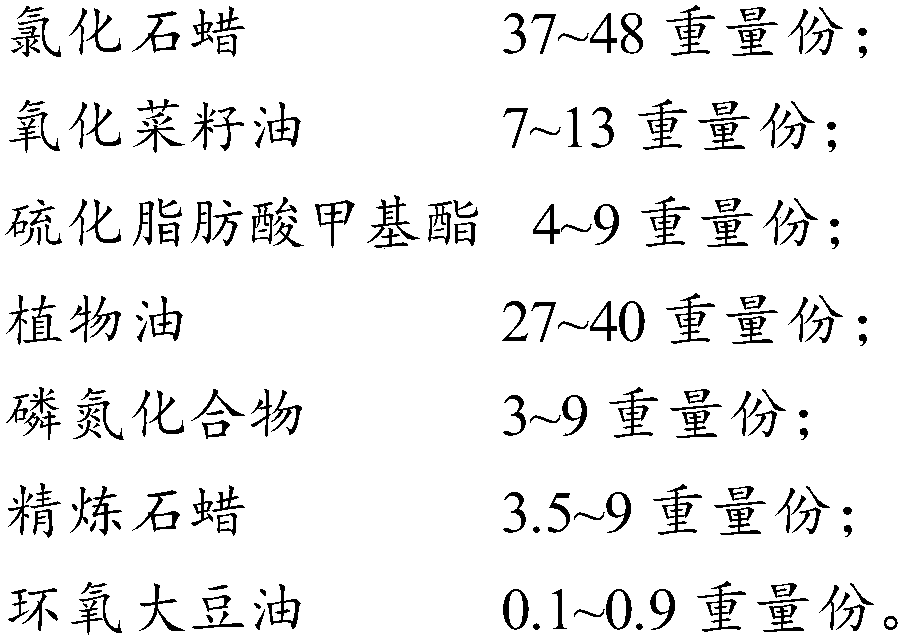

Embodiment 1

[0073]

[0074] Process:

[0075] The refined paraffin is crushed; the above raw materials are added to the production kettle in turn; the temperature is raised to 50-60°C, and stirred for 60 minutes until the product is uniform and transparent. The four-ball data of the product is PB:804N, PD:3920N

Embodiment 2

[0077]

[0078] Process:

[0079] Refined paraffin wax crushed the above raw materials and added them to the production kettle in turn; raised the temperature to 50-60°C and stirred for 60 minutes until the product was uniform and transparent. The four-ball data of the product is PB:980N; PD:4900N

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com