Enhanced type shrinkage-compensating ultrahigh-performance concrete hollow plate hinge joint structure

An ultra-high-performance, shrinkage-compensating technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as bending resistance and shear bearing capacity deviation, achieve high connection strength, good mechanical performance, and avoid shrinkage cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

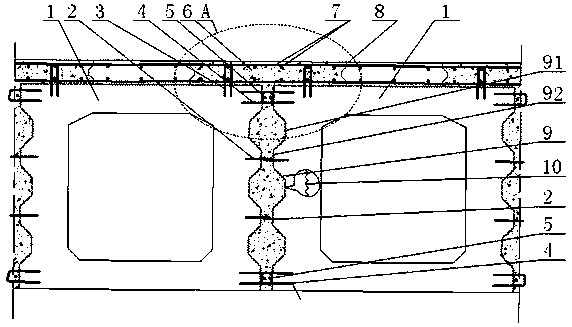

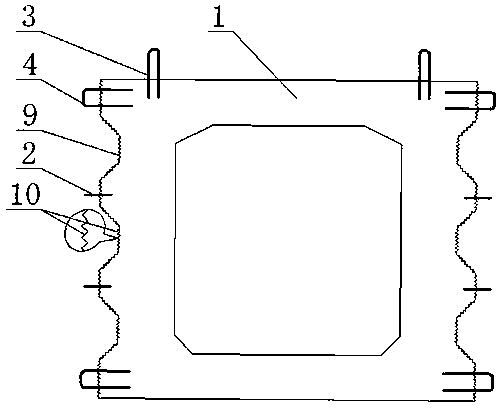

[0031] refer to Figure 1~2 : The reinforced shrinkage-compensated ultra-high-performance concrete hollow slab hinged joint structure of the present embodiment includes web annular anchor bars 4 and plate top annular anchor bars 3 distributed on the outer sides of the webs of two adjacent concrete hollow slabs 1 at the upper and lower ends , seam top steel bar 11 mesh 7, key tooth anchor bar 2 and longitudinal steel bar 5, and the shrinkage-compensating ultra-high-performance concrete 6 cast in the hinge joint of adjacent concrete hollow slabs; the top of the concrete hollow slab 1 is provided with a seam top Steel bars 11 mesh 7 and slab top annular anchor bars 3, slab top annular anchor bars 3 are located on both sides of the hinge joint, and are connected with the seam top steel bars 11 mesh 7; the outer surface of the web of the concrete hollow slab 1 is provided with key teeth 9. The key tooth anchor bar 2 is embedded in the concrete hollow plate 1 located at the protrusi...

Embodiment 2

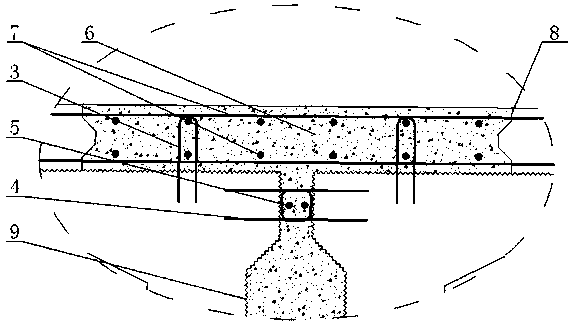

[0042] refer to Figure 4~5 : Compared with Embodiment 1, the reinforced shrinkage-compensated ultra-high-performance concrete hollow slab hinged joint structure of the present embodiment has the following differences:

[0043] The shrinkage-compensating ultra-high-performance concrete 6 is ultra-high-performance concrete with an expansion agent added, and the expansion agent is UEA expansion agent, and its addition amount is 8% W / W of the ultra-high-performance concrete cementitious material, and the ultra-high performance The glue ratio of concrete is 0.18.

[0044] The hinged joint structure also includes a seam top anchor bar 11, which is embedded in the hinge joint of the adjacent concrete hollow slab 1, and the lower end of the seam top anchor bar 11 is handed over to the web annular anchor bar 4, Its upper end is handed over with seam top reinforcing bar 11 mesh 7.

[0045] The construction method of the hinged joint structure comprises the following steps:

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com