Wheel excavator and walking steering method thereof

An excavator and wheeled technology, which is applied in the field of wheeled excavators and their walking and steering, can solve the problems of complex structure of the steering drive axle, high manufacturing cost, and out-of-synchronization of walking, and achieve uniform force, small turning radius, and smooth steering. small radius effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

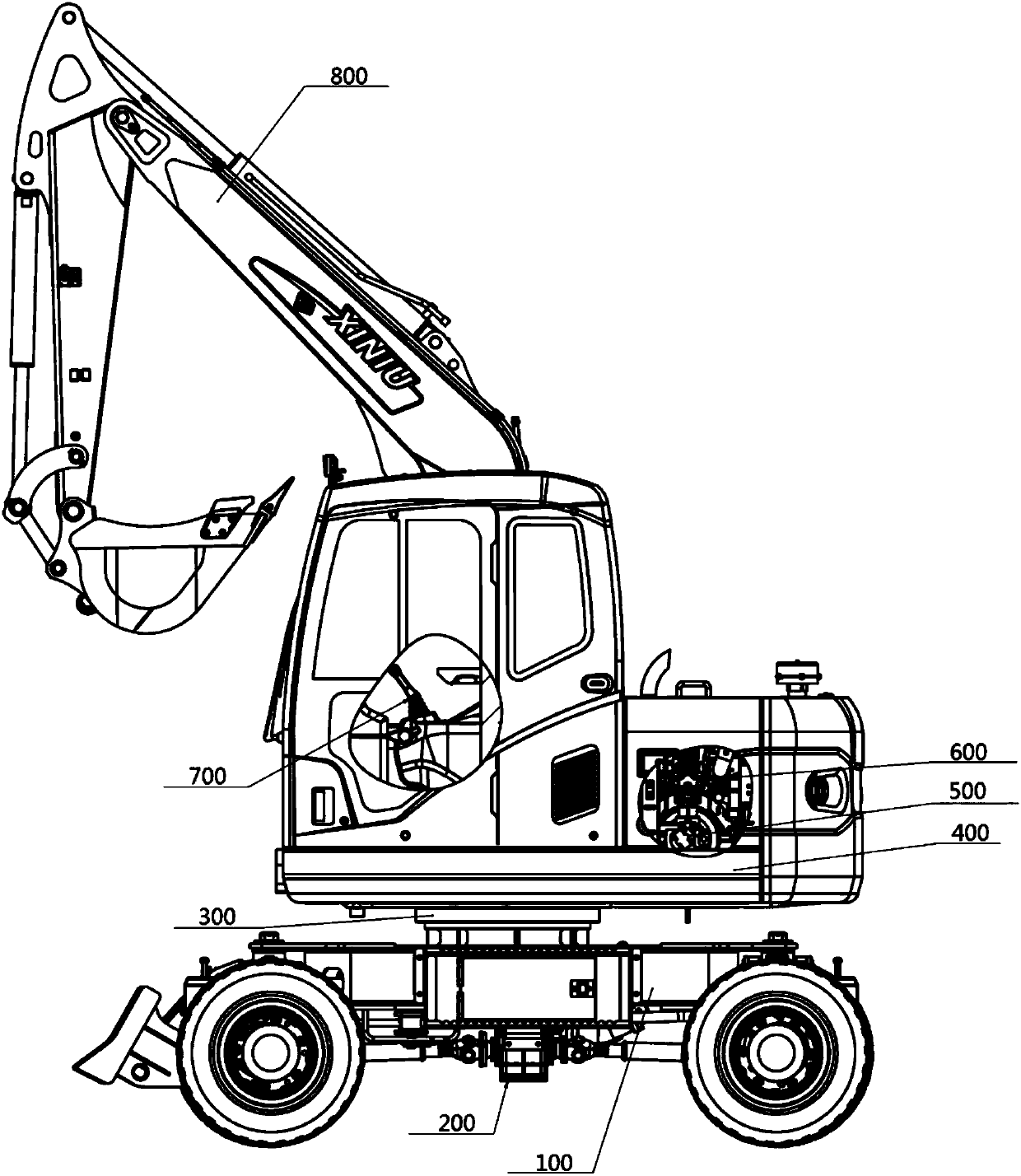

[0054] A wheeled excavator comprises a walking chassis 100, conventional devices such as an upper turntable 400 and an operating device 700 are arranged above the walking chassis, such as figure 1 .

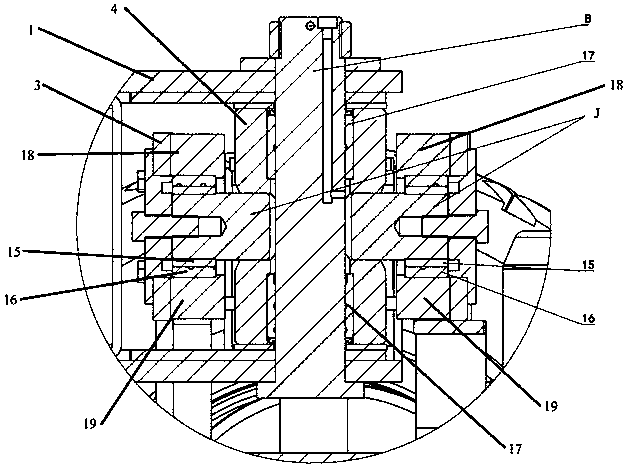

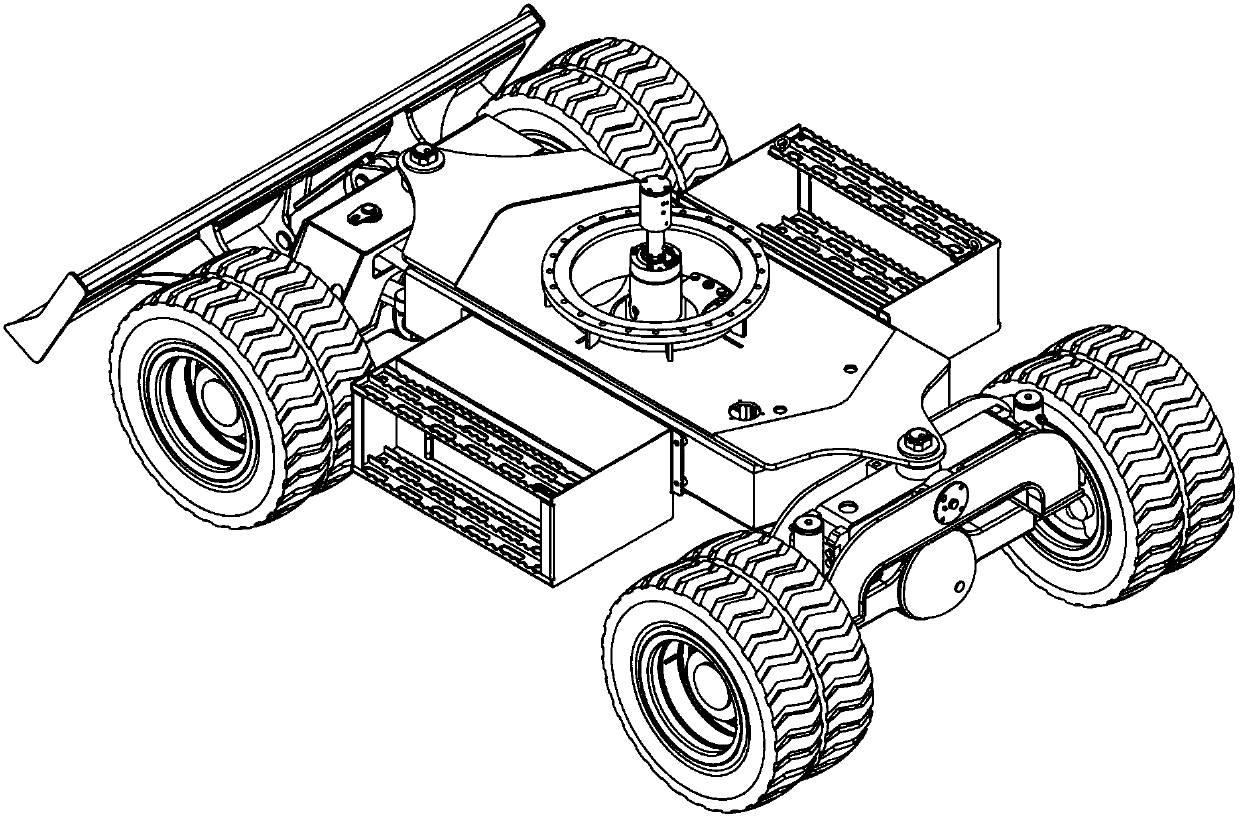

[0055] The walking chassis includes a main frame 1, the two ends of the main frame 1 are provided with a front bridge frame 2 and a rear bridge frame 3, the front bridge frame 2 is provided with a front bridge frame 14, and the rear bridge frame frame 3 is provided with a rear bridge frame 13; The main frame 1 is connected, and the rear bridge is connected with the main frame through the rear vertical shaft.

[0056] The main frame 1 is provided with a steering cylinder 7, a front connecting rod 10, a hinged rod 11, and a rear connecting rod 12. One end of the cylinder barrel of the steering cylinder 7 is connected with the main frame 1 through the rear shaft G of the steering cylinder, and one end of the piston rod of the steering cylinder 7 is It is hinged with the front bridg...

Embodiment 2

[0059] A wheeled excavator, its structure is as described in Embodiment 1, the difference is that the position where the front connecting rod is hinged with the front bridge frame and the position where the piston rod of the steering cylinder is hinged with the front bridge frame coincide, as Figure 8b Among them, one end of the piston rod of the front connecting rod and the steering cylinder is hinged to the front bridge through the steering cylinder, the front axle C of the front connecting rod at the same position. When the piston rod of the steering cylinder controls the rotation of the front axle by telescoping, the reaction time of the front connecting rod can be saved.

Embodiment 3

[0061] A wheeled excavator, its structure is as described in Embodiment 1, the difference is that the steering cylinder and the front connecting rod are not in the same horizontal plane. Such as Figure 8a , Figure 8b As shown, the two have a staggered distribution in the horizontal direction to avoid mutual influence on the transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com