Air electrode and manufacturing method thereof

A technology of air electrode and manufacturing method, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, etc., and can solve the problems of unstable gas-liquid-solid three-phase interface, reduced reaction site, and large internal resistance of air electrodes, etc. problems, achieve the effect of maintaining the balance of the gas-liquid-solid three-phase interface, stabilizing the reaction site, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

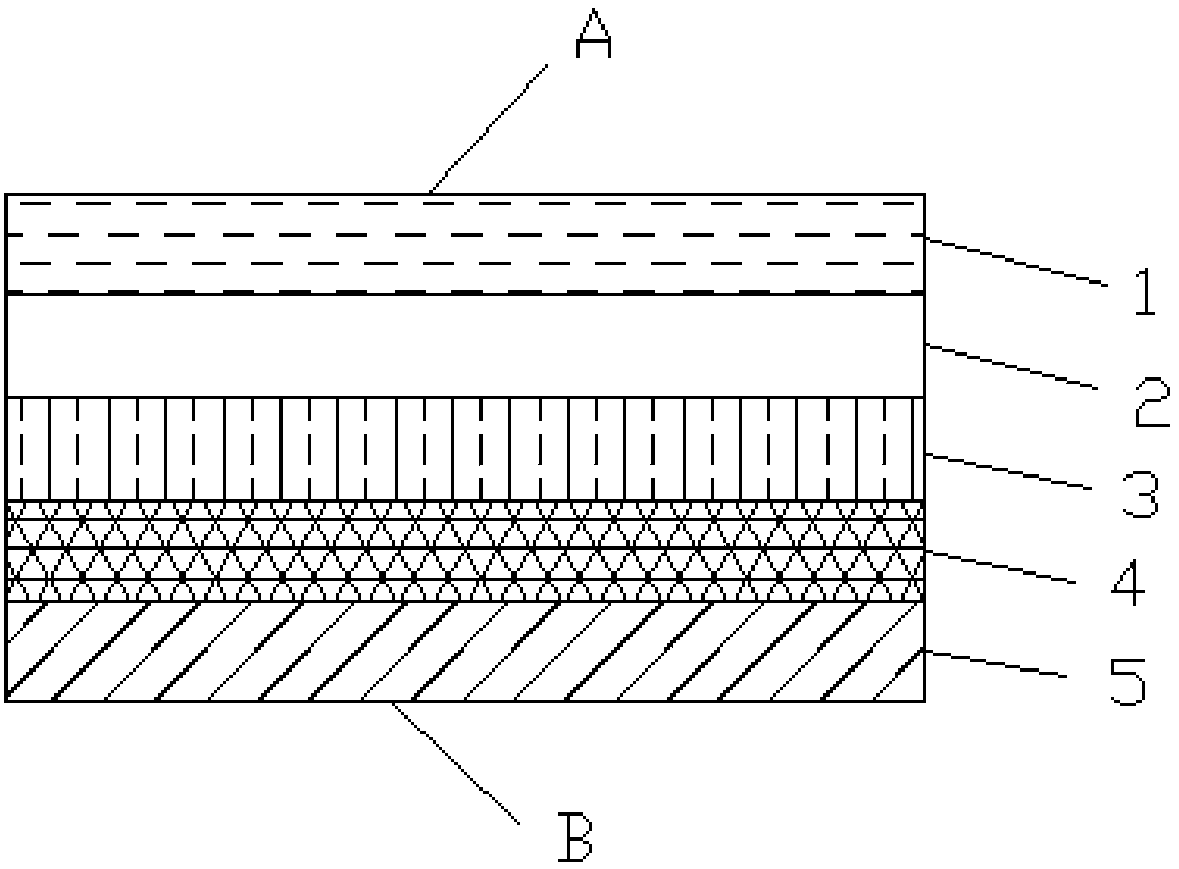

[0040] (1) Mix 30g of activated carbon, 30g of manganese dioxide, and 30g of graphite with 10g of polytetrafluoroethylene emulsion (solid content: 30%) and roll to make catalytic layer 1 for later use;

[0041] (2) Select 30g of activated carbon, 20g of manganese dioxide, and 30g of graphite to mix with 20g of polytetrafluoroethylene emulsion (solid content: 30%) and roll to form the reflection layer 2 for later use;

[0042] (3) Mix 10g of activated carbon with 40g of carbon black, then add 50g of polyvinylidene fluoride emulsion (solid content: 60%), mix and roll to form a hydrophobic layer 3 for later use;

[0043] (4) Select 70g of carbon black and 30g of polyvinylidene fluoride emulsion (solid content: 60%) to mix and roll to form a breathable protective layer 5 for later use;

[0044] (5) The catalytic layer 1, the reaction layer 2, and the hydrophobic layer 3 are sequentially arranged on the upper side of the current collector 4, and the breathable protective layer 5 is...

Embodiment 2

[0046] (1) Select 50g of activated carbon, 30g of carbon-supported platinum and 10g of graphite and mix them with 10g of polyvinylidene fluoride emulsion (solid content: 40%) to mix and roll to form catalytic layer 1 for later use;

[0047] (2) Mix 50g of activated carbon, 30g of carbon-supported platinum, and 20g of graphite, and then mix with 10g of polyvinylidene fluoride emulsion (solid content: 50%) to form a reflection layer 2 for later use;

[0048] (3) Select 10g of activated carbon and 40g of carbon black to mix, then add 50g of polytetrafluoroethylene emulsion (solid content: 60%) and mix and roll to form a hydrophobic layer 3 for later use;

[0049] (4) Select 70g of carbon black and 30g of polytetrafluoroethylene emulsion (solid content is 40%) mixed and rolled to make breathable protective layer 5 for later use;

[0050] (5) The catalytic layer 1, the reaction layer 2, and the hydrophobic layer 3 are sequentially arranged on the upper side of the current collector...

Embodiment 3

[0052] (1) Mix 20g of activated carbon, 35g of platinum on carbon, and 25g of graphite with 20g of polytetrafluoroethylene emulsion (solid content: 30%) and roll to make catalytic layer 1 for later use;

[0053] (2) Select 40g of activated carbon, 20g of carbon-supported platinum, and 20g of graphite to mix and then mix with 20g of polytetrafluoroethylene emulsion (solid content: 30%) and roll to form the reflection layer 2 for later use;

[0054](3) Select 20g of activated carbon and 50g of carbon black to mix, then add 30g of polytetrafluoroethylene emulsion (solid content is 40%), mix and roll to form a hydrophobic layer 3 for later use;

[0055] (4) Select 75g of carbon black and 25g of polytetrafluoroethylene emulsion (solid content is 35%) mixed and rolled to make breathable protective layer 5 for later use;

[0056] (5) The catalytic layer 1, the reaction layer 2, and the hydrophobic layer 3 are sequentially arranged on the upper side of the current collector 4, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com