A plug-in throttle valve group for a rod-type hydrostatic cylinder

A technology of restrictors and cartridge valves, which is applied in fluid pressure actuation devices, servo motor components, fluid pressure actuation system testing, etc., can solve the problems of heavy overall structure, no significant improvement in cost performance, complicated use, etc., and achieve Easy mass production, novel structure, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

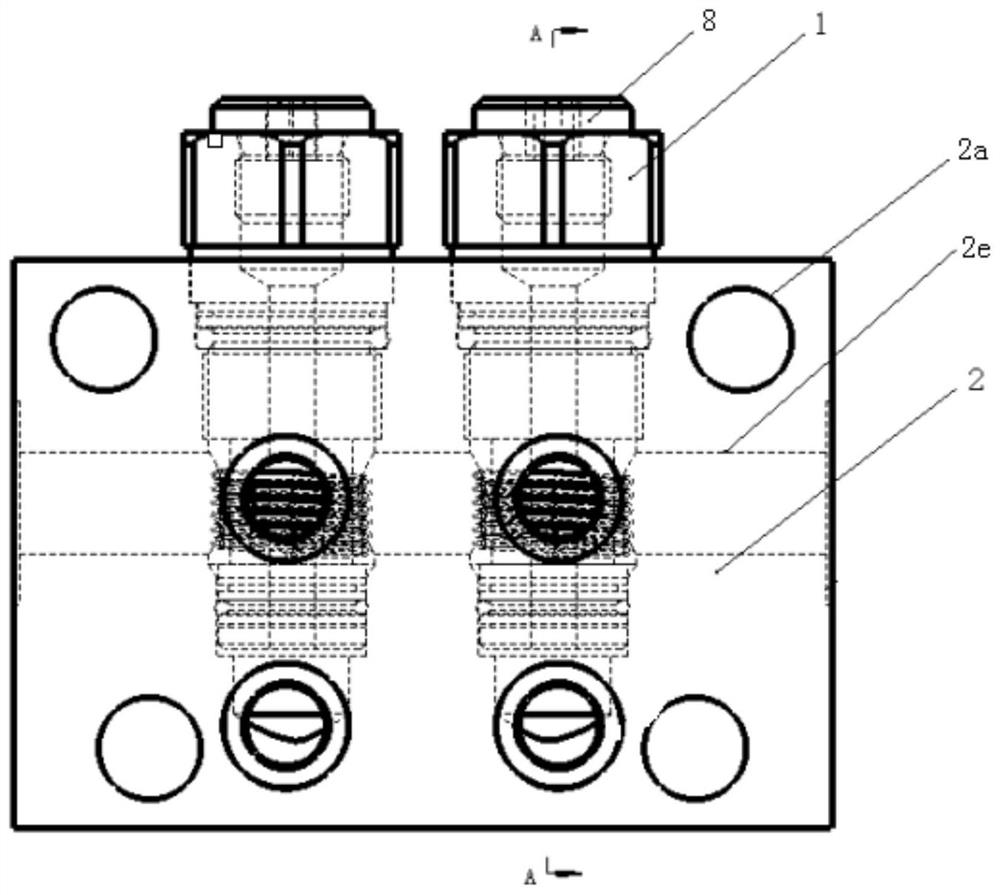

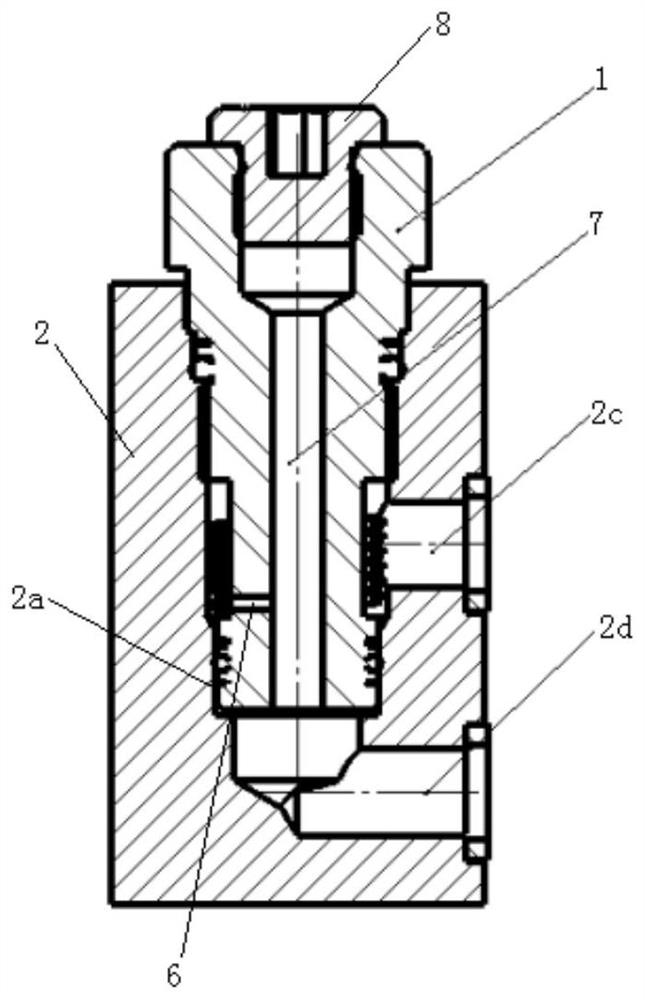

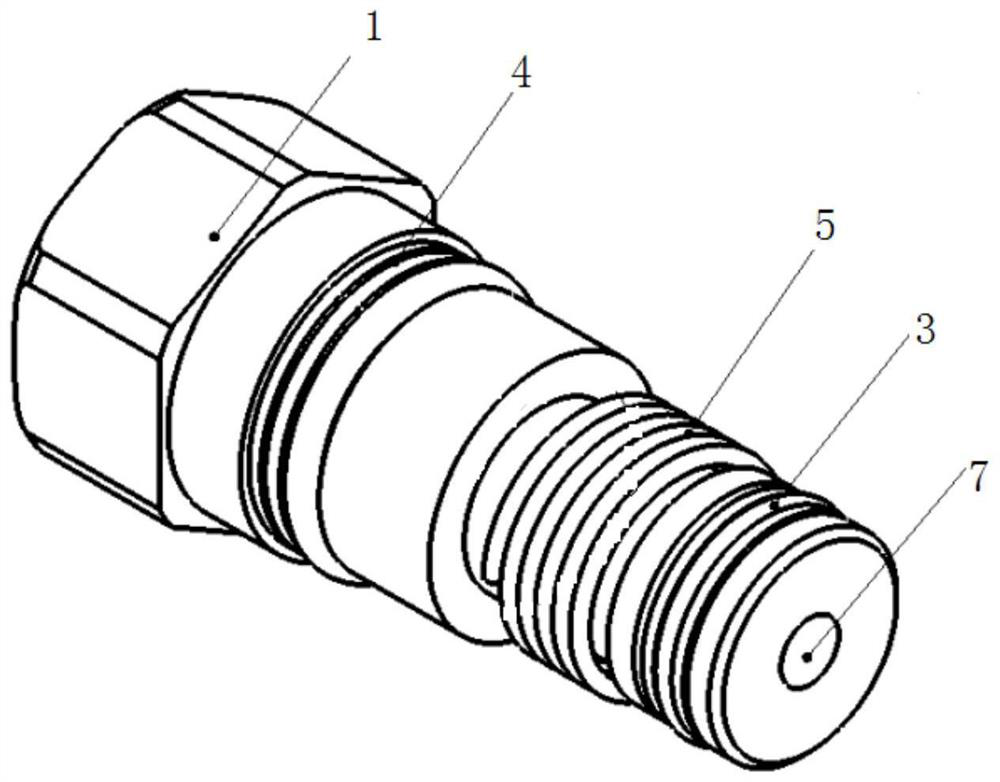

[0022] combine figure 1 — image 3 As shown, a plug-in throttle valve group for a rod-type hydrostatic cylinder is mainly composed of a throttle 1, a cartridge valve body 2, an inner seal ring 3, an outer seal ring 4, a capillary tube 5, and a plug 8 composition.

[0023] The cartridge valve body 2 is provided with a throttle installation hole 2a, and the throttle 1 is inserted into the throttle installation hole 2a of the cartridge valve body 2 through threads, and the throttle 1 is inserted into the throttle installation hole 2a And the two are installed together by threading. The cartridge valve body 2 is provided with a valve body installation hole 2b, which is used to install itself on the end cover of the tie rod type oil cylinder.

[0024] Have an axial through hole in the restrictor 1 as the pressure measuring center hole 7, and the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com