A Slurry Recovery System for Selective Laser Melting Forming

A recycling system and laser melting technology, applied in the field of additive manufacturing, can solve the problems of difficult to handle slurry, waste, difficult recycling and reuse of metal powder and reinforcement materials, etc., and achieve the effect of reducing the cost of SLM molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

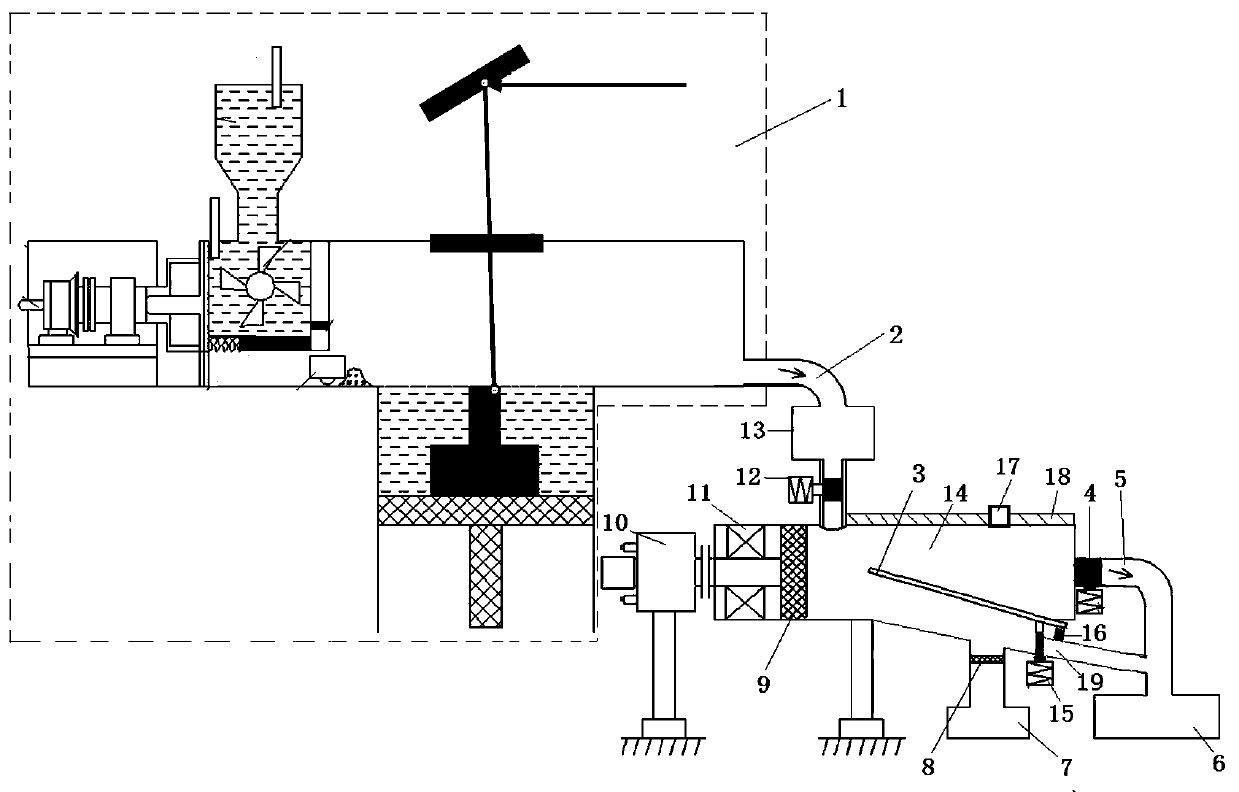

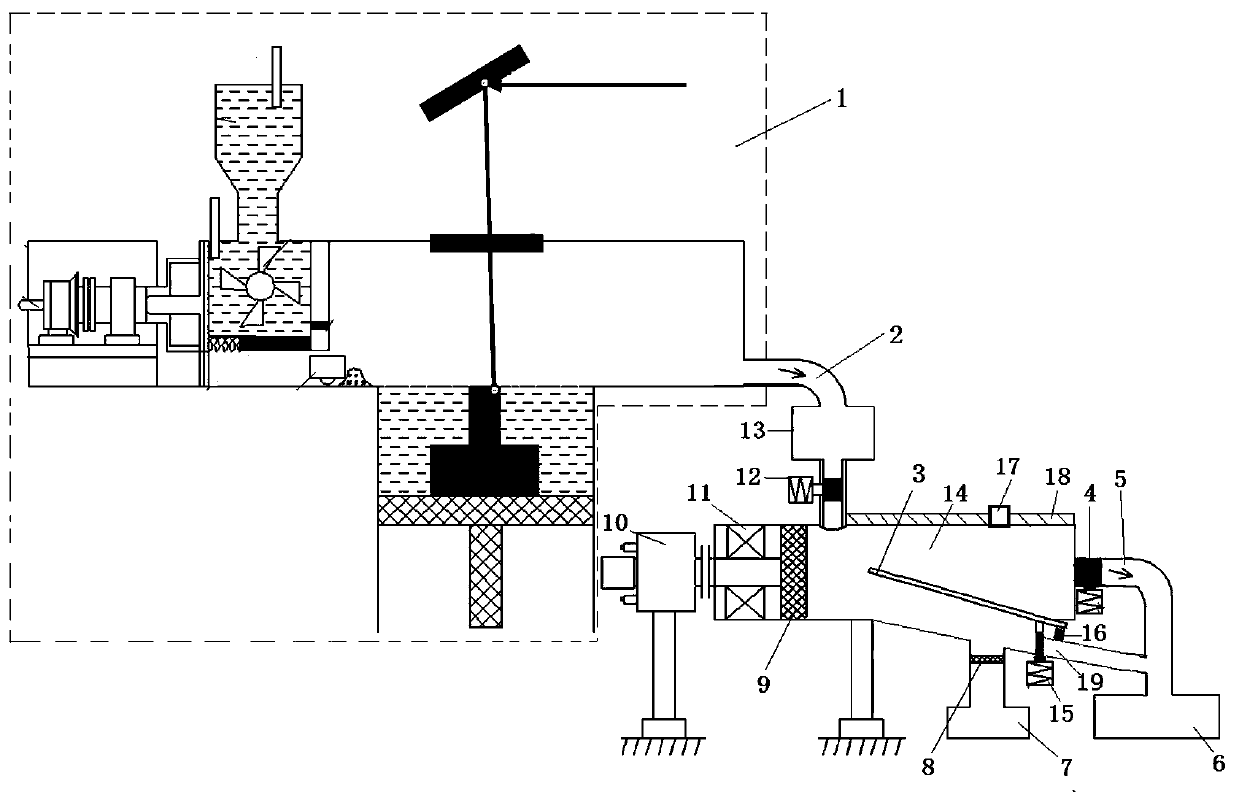

[0025] The structure of selective laser melting forming slurry recovery system is as follows: figure 1 shown. The main body of the slurry recovery system is a solid-liquid separation chamber 14 . The forming system 1 is sealed and connected with the material receiving port 2, the sealing grade is IP67, the material of the material receiving port 2 is aluminum alloy tube, and the material receiving angle is 75°. A transfer bin 13 is installed at the lower end of the material receiving port 2, the material receiving port 2 is sealed and connected with the transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com