Pervious concrete and production method thereof

A technology of permeable concrete and concrete, which is applied to ceramic products, other home appliances, and cohesive pavement paved on site. The effect of freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

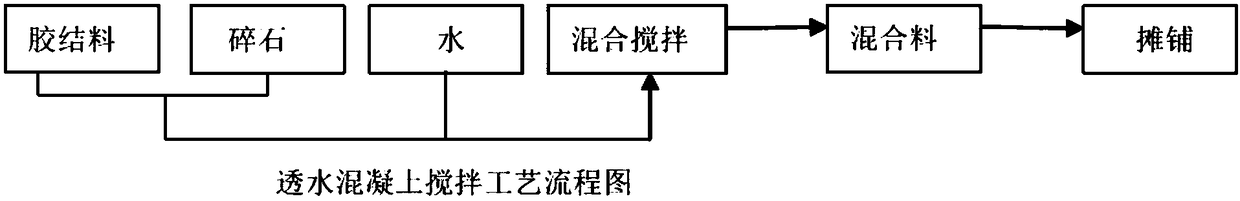

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0049] The object of the present invention is to provide a kind of permeable concrete and preparation method thereof, specifically:

[0050] 1) Preparation before construction

[0051] Cement: choose portland cement above grade 42.5, or slag cement or rapid hardening cement; in order to improve its strength, a small amount of highly active mixed materials, such as silica fume, can be added.

[0052] Aggregate: The gradation of aggregate is an important indicator to determine its strength and water permeability. In order to ensure strength and good water permeability, coarse aggregate should use a single particle size with a small particle size; such as 10-20mm. In addition, there are corresponding requirements for the strength of the aggregate itself, particle shape (needle, flake content) and mud content.

[0053] Admixtures: including high-efficiency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com