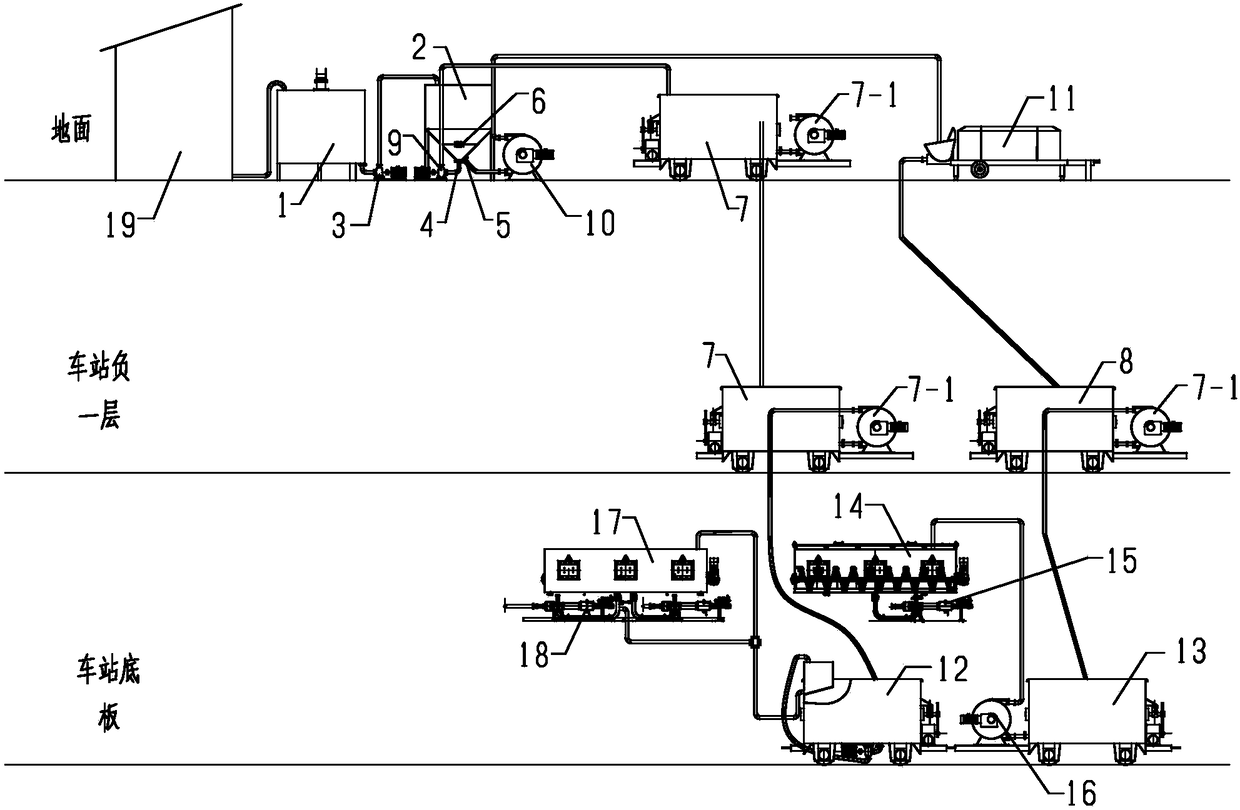

Novel grouting system and grouting technology for effectively controlling land subsidence

A technology of ground subsidence and grouting system, applied in underground chambers, wellbore linings, tunnel linings, etc., can solve the problems of difficult settlement, effective control of land subsidence, etc., to prevent further expansion of subsidence, avoid land subsidence, and achieve ideal results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

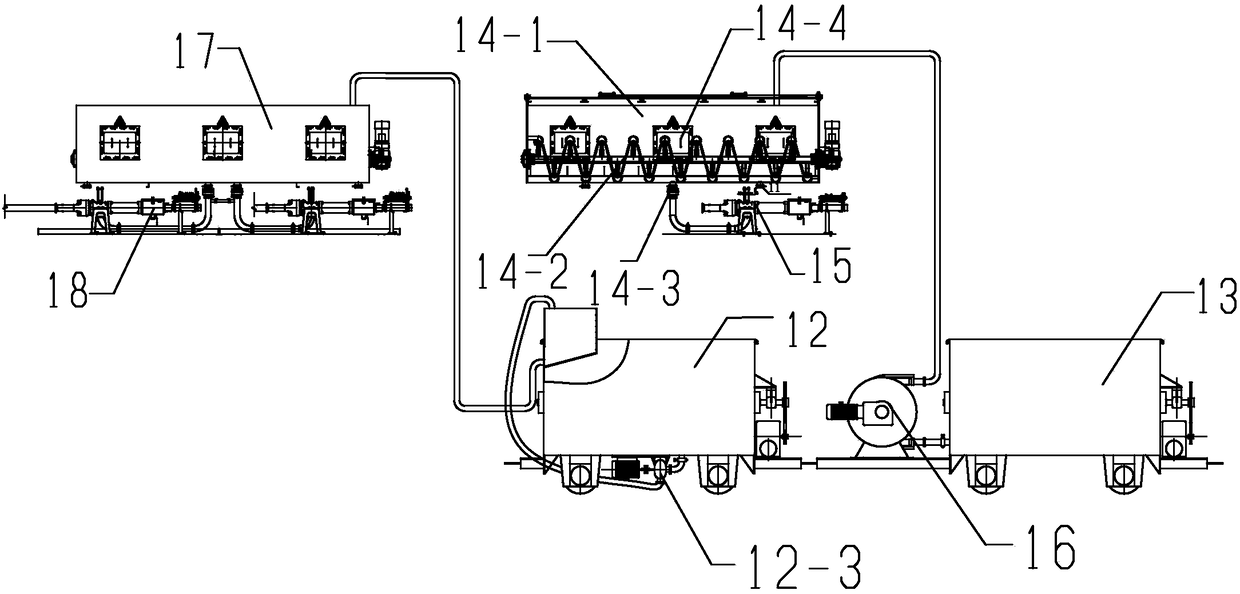

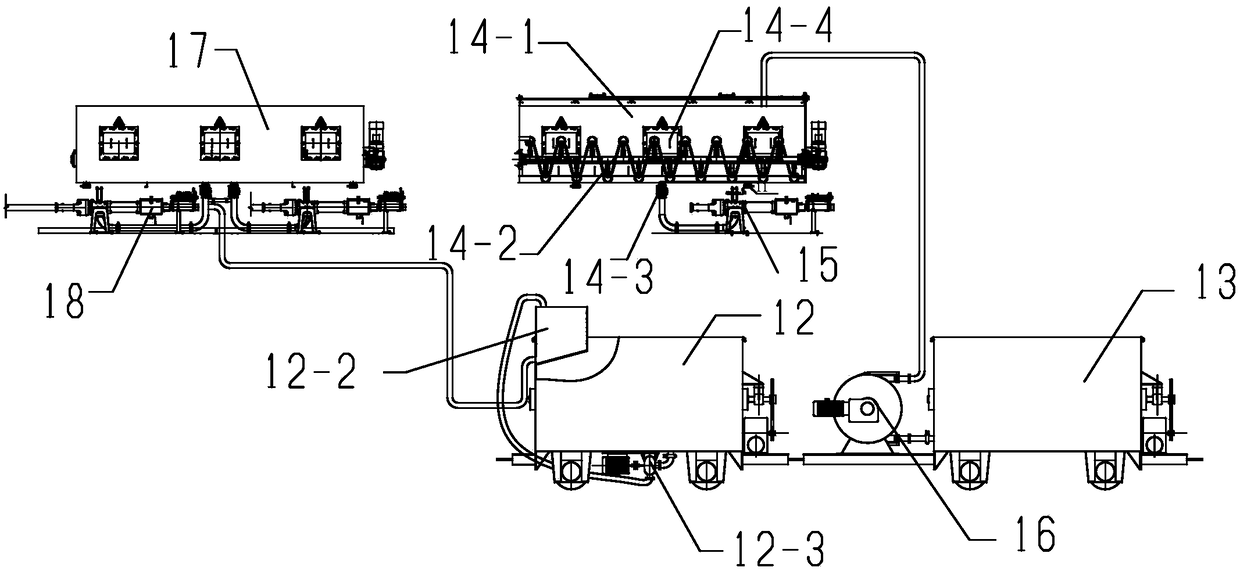

[0032] Embodiment 1: This embodiment is aimed at the machine-weighted section of the Shenzhen World Convention and Exhibition Center. The stratum in this shield section passes through four subway operation lines in the upper soft and lower hard strata, which has extremely high requirements for settlement control and difficult shield tunneling construction. The settlement control of the upper soft and lower hard strata itself is a major problem in the field of shield tunneling construction, and the construction of the upper soft and lower hard stratum passing through the existing line is even more difficult. There is a project in Shenzhen that passes through an unoperated subway line in a similar stratum. The settlement control has seriously exceeded the standard, and the post-processing is difficult and expensive. The inventor adopts the method among the present invention to carry out timely radial grouting, and its specific process steps are as follows:

[0033] (1) Prepare n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com