Adjustable resonance frequency method of series induction heating power supply based on current compensation

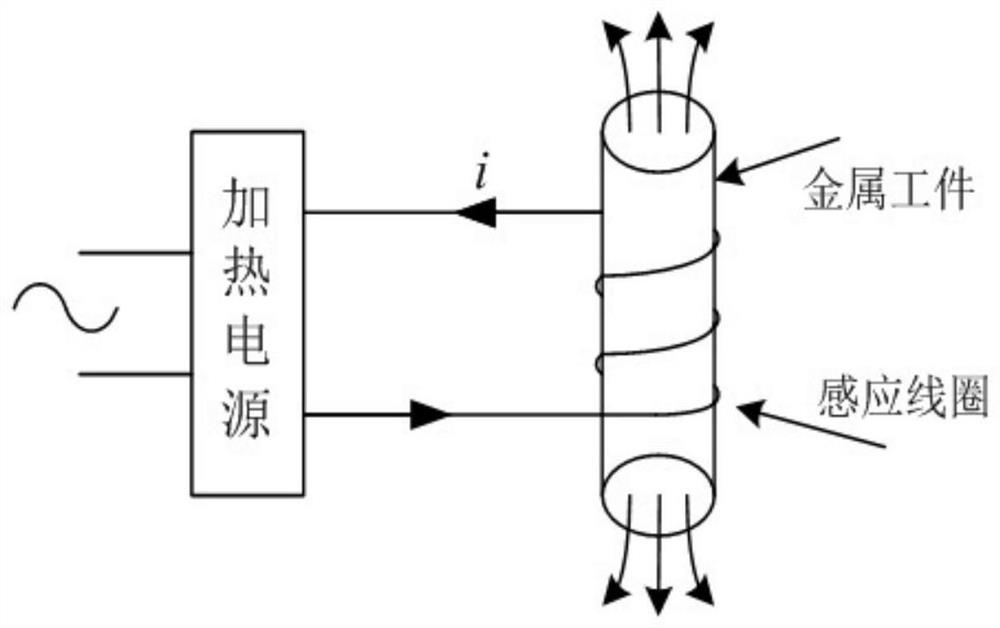

A technology of induction heating power supply and resonant frequency, which is applied in the direction of induction heating, induction heating control, induction current source, etc., can solve the problems of large frequency change, low accuracy, large fluctuation, etc., to ensure the process level and reduce the Harmonic pollution, ensure the effect of heating depth requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

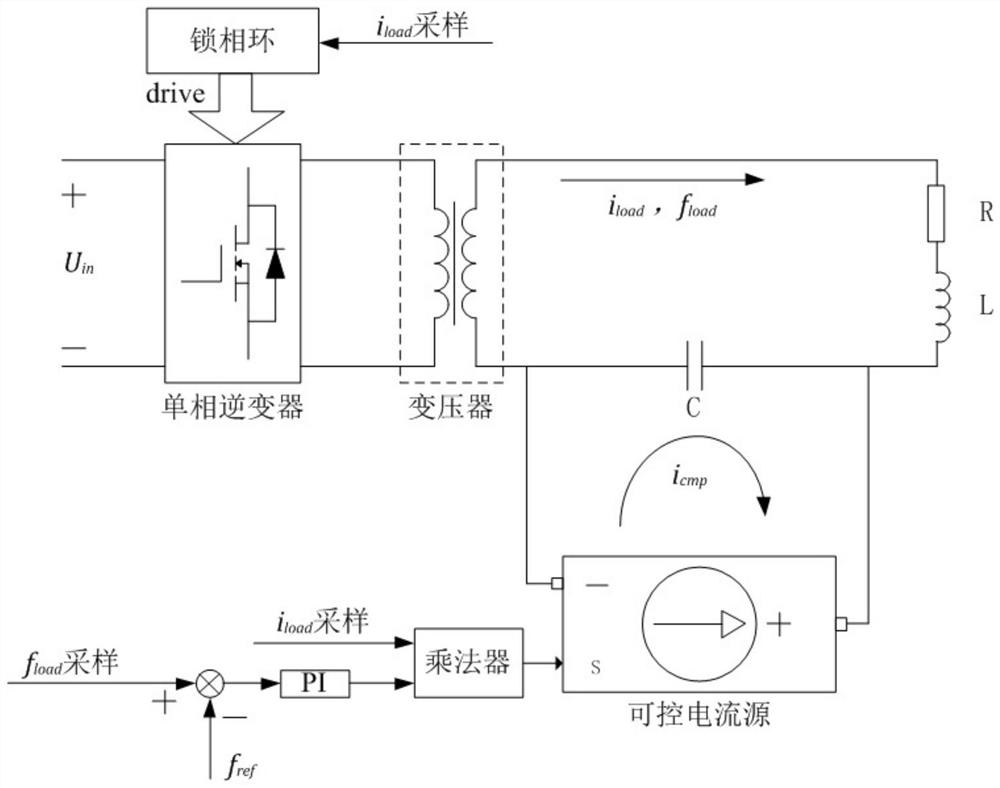

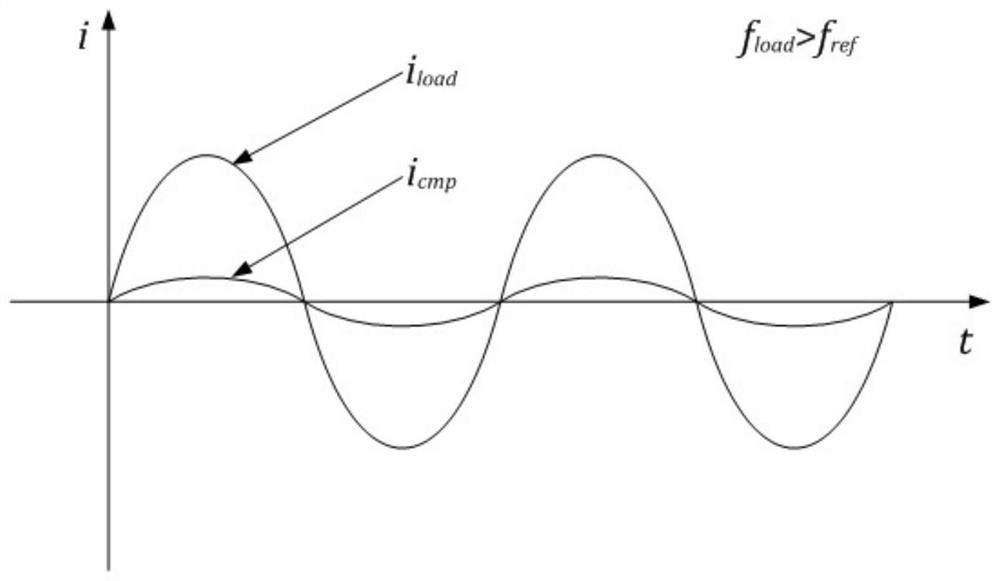

[0033] Such as figure 2 , the method for adjusting the resonant frequency of the series induction heating power supply based on current compensation in this embodiment includes a DC voltage source Uin, a single-phase inverter, a transformer, a resistor R, an inductor L, a capacitor C, a phase-locked loop, and a PI controller , a multiplier, and a controllable current source; wherein the resistance R and the inductance L are equivalent loads of the induction heating system, and are connected in series with the capacitance C to form an RLC resonant circuit. image 3 and Figure 4 It shows the output compensation current i of the adjustable capacitor when the frequency is too high or too low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com