A multifunctional mechanical workbench capable of multi-angle machining work

A multi-angle and multi-functional technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of inconvenient processing, poor operation effect, difficult operation, etc., to improve operation efficiency, convenient operation and time saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

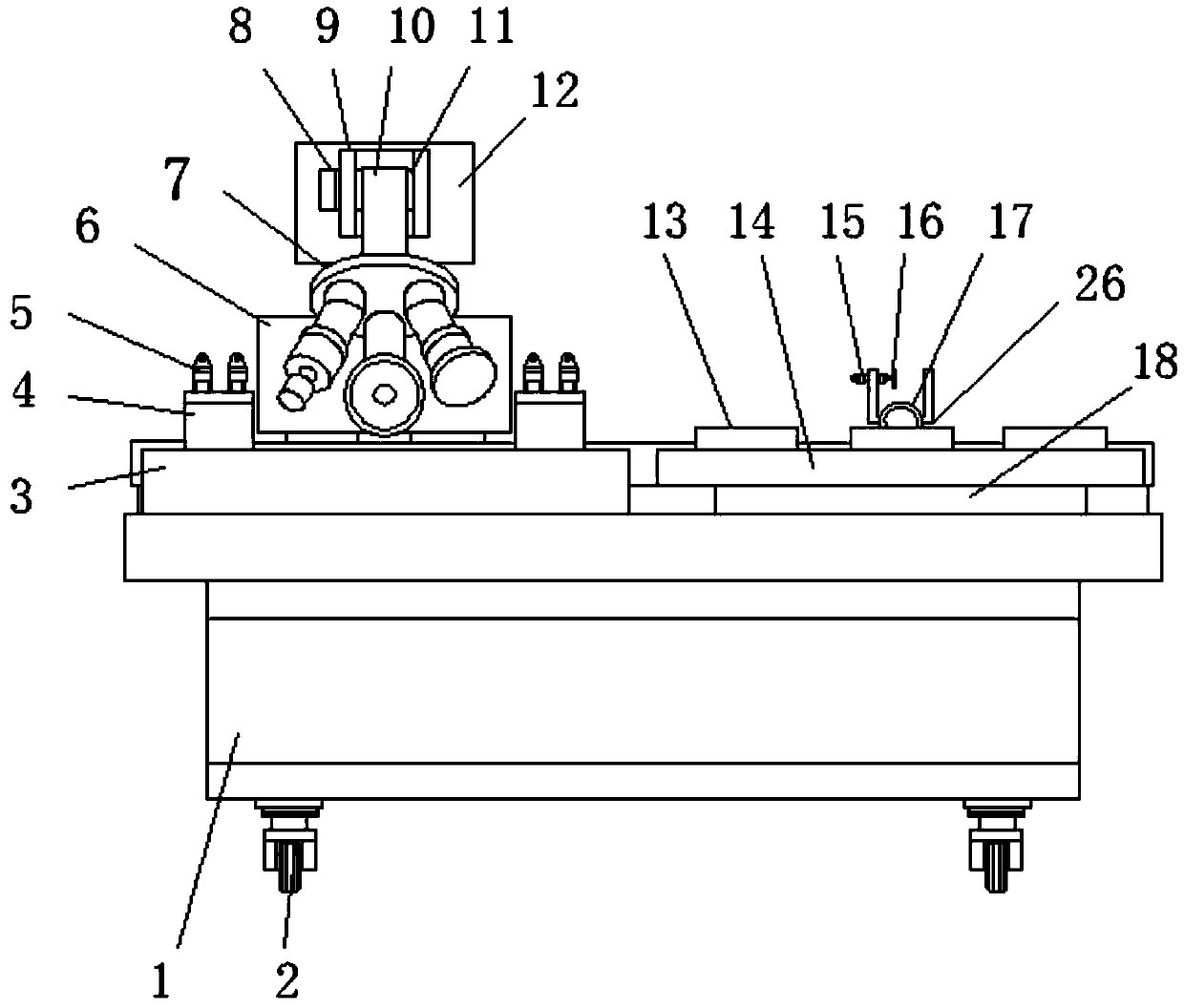

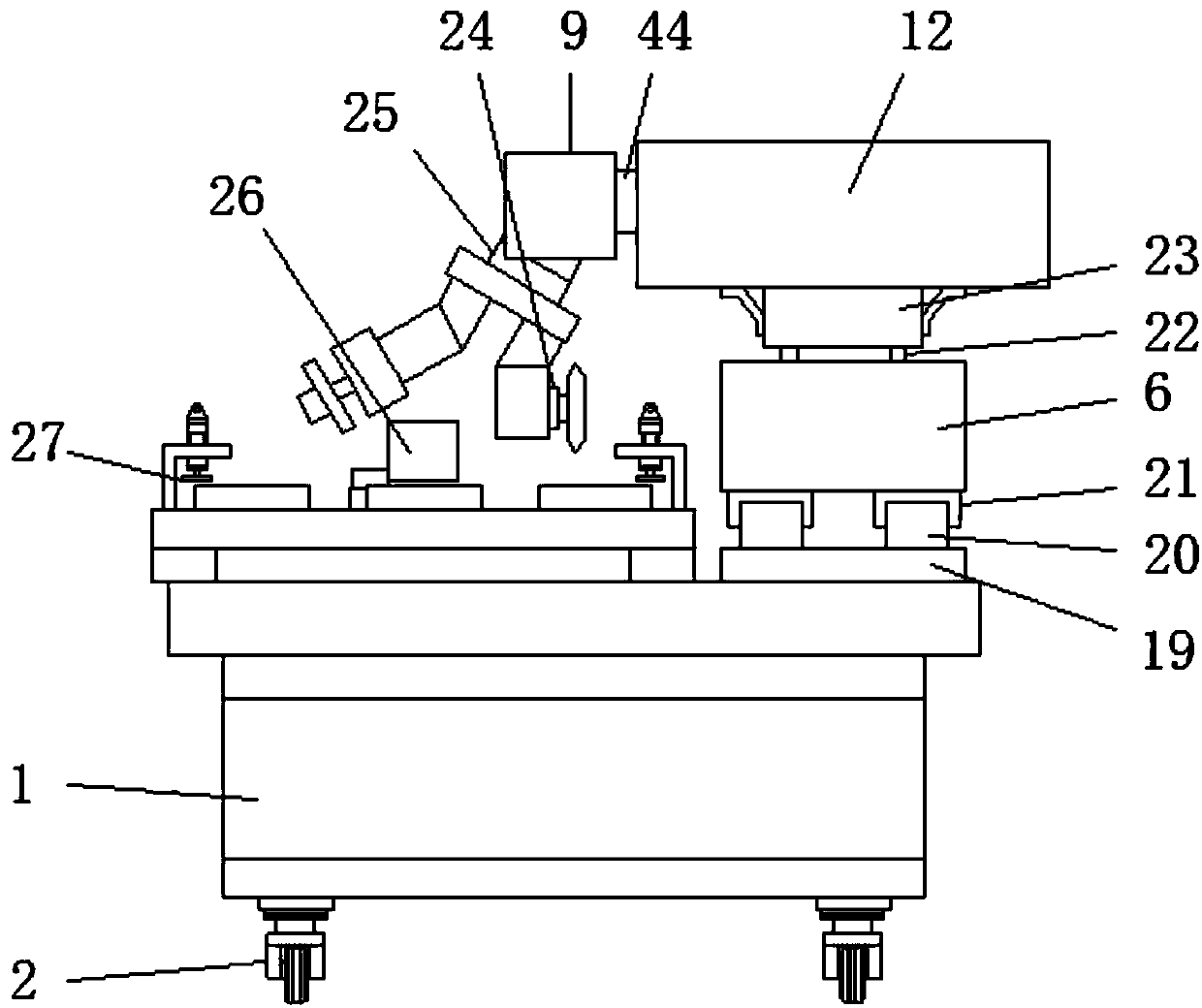

[0027] Example 1, such as figure 1 , Figure 5 First, the cutting object is placed on the cutting table 3, and the object is fixed on the cutting table 3 by the L-shaped splint 4 and the first pneumatic cylinder 5. First, the third rotating motor 25 drives the turntable 7, and the cutting blade 34 is adjusted to the working position. The first electromagnetic slide rail 20 and the first electromagnetic slide block 21 can be used to move to the designated position above the cutting table 3, and the second electromagnetic slide rail 39 and the second electromagnetic slide block 40 make the sliding column 44 slide, further to The position of the cutting blade 34 is adjusted, and then the lifting air cylinder 42 drives the cutting blade 34 to move up and down, so that the cutting blade 34 is in contact with the parts to be cut, and drives the cutting blade 34 to run to cut the parts. And the first electromagnetic slider 21 drives the cutting part to move.

Embodiment 2

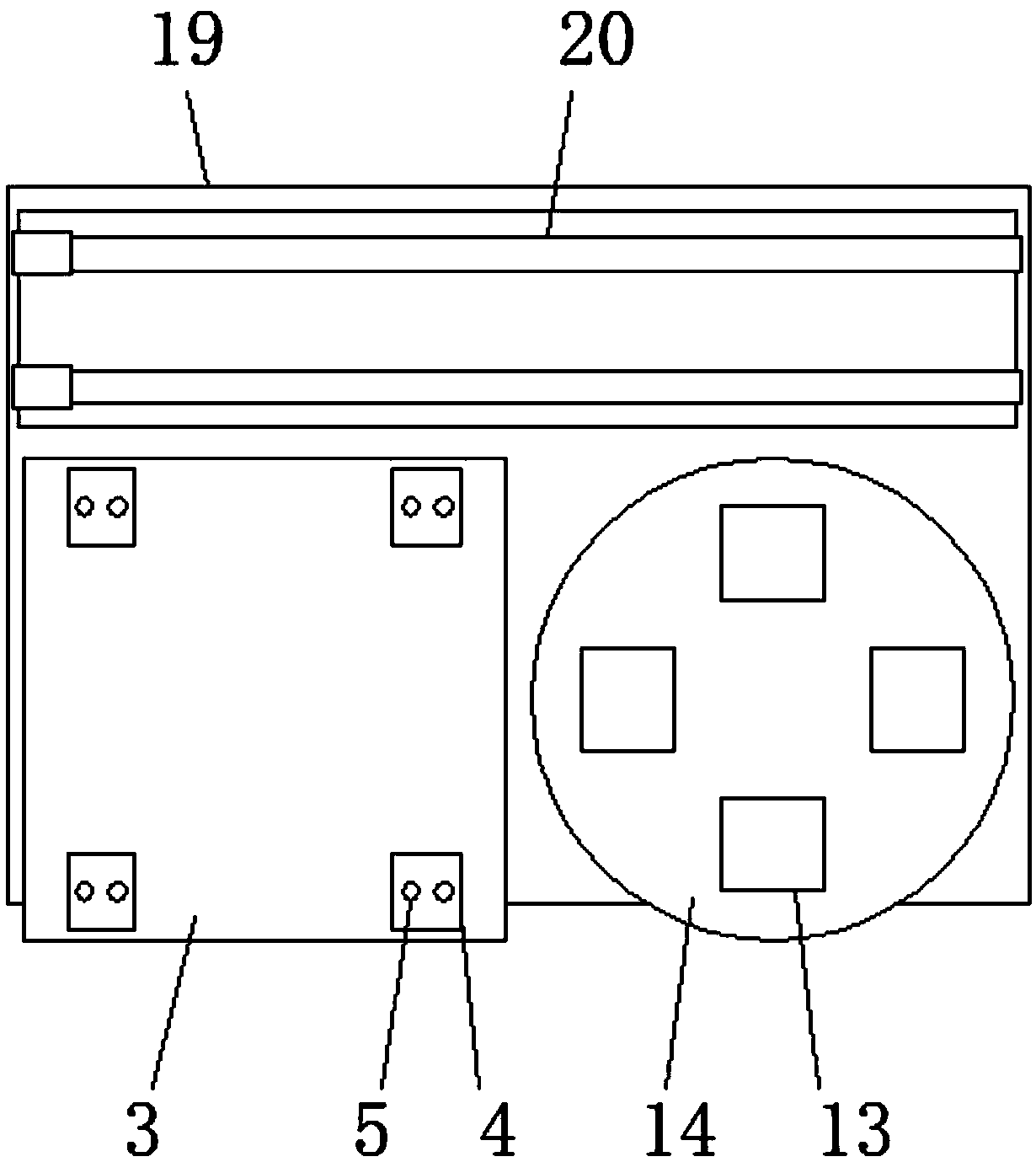

[0028] Example 2, such as figure 1 , Figure 4 When the regular object is polished, the grinding piece can be placed inside the placement groove 13, the object is fixed inside the placement groove 13 by the fixed spring 45 and the splint 46, and then passed through the first electromagnetic slide rail 20 and the first electromagnetic slide block 21. Adjust the position of the second mounting base 12, adjust the sliding column 44 with the second electromagnetic slide rail 39 and the second electromagnetic slider 40, so that the working part is located above one of the placement slots 13, driven by the third rotating motor 25 The turntable 7 rotates to adjust the grinding head 31 to the working position. The lifting air cylinder 42 controls the lifting of the working position to adjust the grinding head 31 to a specified height. The first grinding motor 30 drives the first grinding motor 30 to grind the object. At the same time, other stations are loaded. After the polishing is...

Embodiment 3

[0029] Example 3, such as figure 1 , Figure 4 When it is necessary to polish irregular objects, the irregular objects are placed inside the U-shaped splint 26, and the object is fixed by the second air cylinder 15 and the splint 16. The disc 35 is adjusted in the working position, and the grinding head 31 or the grinding disc 35 is driven by the first grinding motor 30 and the second grinding motor 36 respectively to grind the specified position. When grinding at different angles is required, the first The rotating motor 8 drives the rotating shaft 11 to rotate, thereby adjusting the inclination angle of the working part. At the same time, the second rotating motor 17 drives the fixed part to rotate, thereby adjusting the inclination angle of the object. The fourth rotating motor 48 drives the fixed part to rotate, so that different surfaces of the object can be polished.

[0030] Working principle: Before use, move the device to the designated position through the universa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com