Sintered product bearing mechanism

A bearing mechanism and product technology, applied in the field of sintering technology, can solve the problems of low yield rate, easy deformation and fracture of the bearing plate, etc., and achieve the effect of improving yield rate, reducing local stress, and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

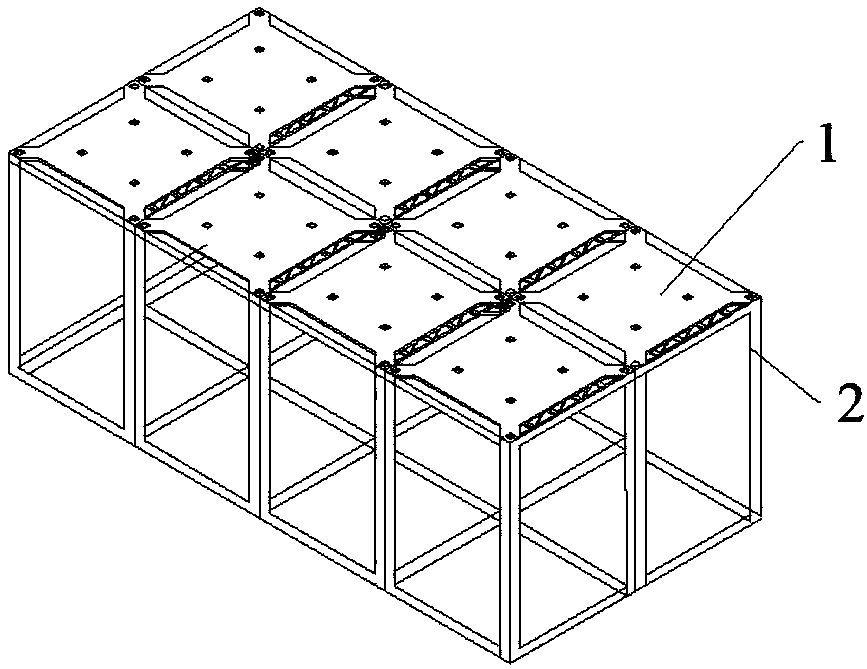

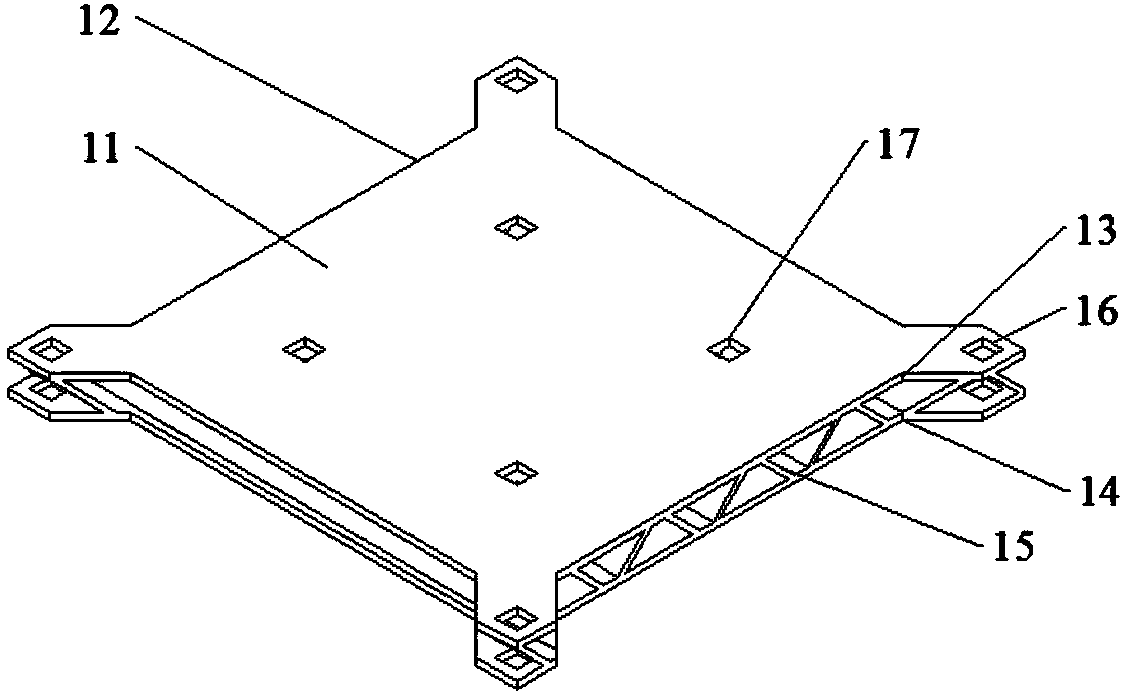

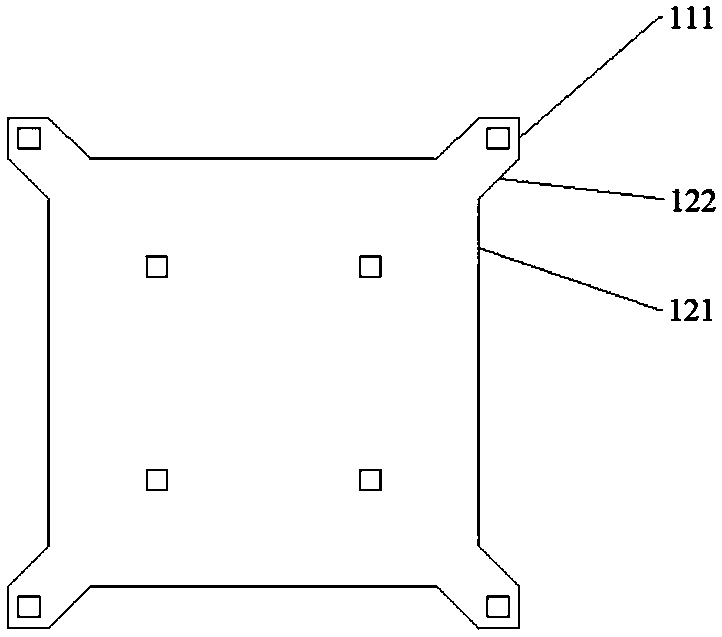

[0027] see figure 1 , is a structural schematic diagram of a sintered product carrying mechanism, composed of figure 1 It can be seen that the sintered product carrying mechanism provided by the present application includes a carrying plate 1 and a sintering frame 2 used in conjunction with the carrying plate 1, wherein the carrying plate 1 includes a square carrying body 11 and a Fire path groove 12 on four sides. In this embodiment, the carrying plate 1 can be made in the following manner. The material of the carrying plate 1 is formed into a square plate-shaped carrying body 1, and then a certain amount of material is cut off from the four sides of the square to form four flames. groove 12, and then through mechanical processing, the edge of the material is polished to a larger rounded corner, and finally formed figure 2 The structure of the carrier plate 1 is shown.

[0028] The carrying body 11 includes a carrier layer 13 in contact with the sintered product, a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com