Automatic blanking device for conveying battery pieces

An automatic feeding and conveying device technology, which is applied in the field of solar cells, can solve the problems of equipment suspension, waste of production time, and increased labor costs, and achieve the effects of reducing labor costs, equipment suspension, and cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

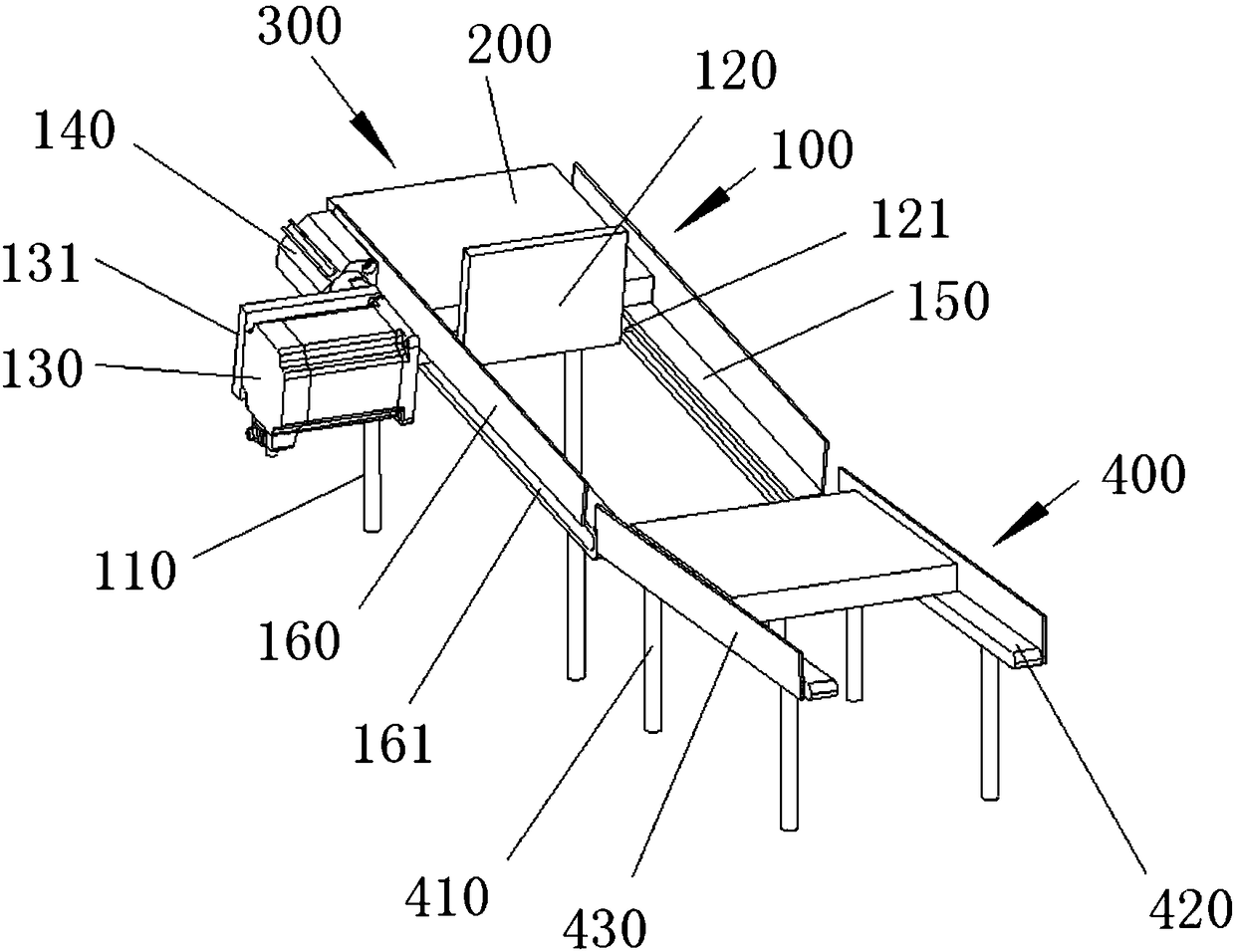

[0033] Such as figure 1 and figure 2 As shown, the automatic unloading device for conveying battery sheets in this embodiment includes:

[0034] The first conveying device 100, the first conveying device 100 comprises a first support 110, a turning block 120, a turning drive 130, a linear reciprocating drive 140 and two first conveyor belts 150, and two first conveying belts 150 are arranged on the first support 110. The side plate 160, the two first conveyor belts 150 are arranged between the two first side plates 160, the two first conveyor belts 150 are arranged side by side at intervals, the turning stopper 120 is slid on the two first side plates through the rotating shaft 121 160, and the width of the steering block 120 is less than the distance between the two first conveyor belts 150, the steering drive 130 drives the steering block 120 to turn over, and the linear reciprocating drive 140 drives the steering block 120 to reciprocate along the conveying direction,

...

Embodiment 2

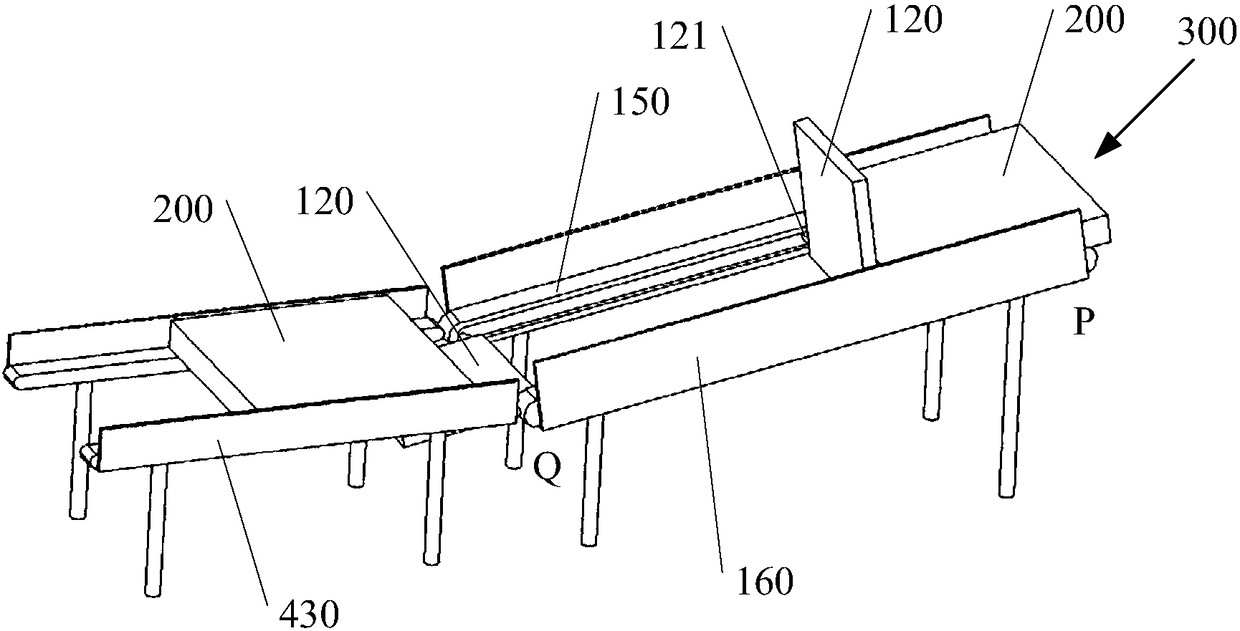

[0043] Such as image 3 As shown, the principle of this embodiment is the same as that of Embodiment 1, the difference is:

[0044] In the automatic unloading device for conveying battery sheets in this embodiment, the steering block 120 is vertically fixed on the two first conveyor belts 150 , and the width of the steering block 120 is smaller than the distance between the two first conveyor belts 150 . The turning stopper 120 can move synchronously with the first conveyor belt 150 .

[0045] In this embodiment, there are two turning blocks 120 , one turning block 120 is set at the input end of the first conveyor belt 150 , and the other turning block 120 is set at the output end of the first conveyor belt 150 . The two steering blocks 120 are cyclically alternated, which greatly shortens the production time and improves the working efficiency.

Embodiment 3

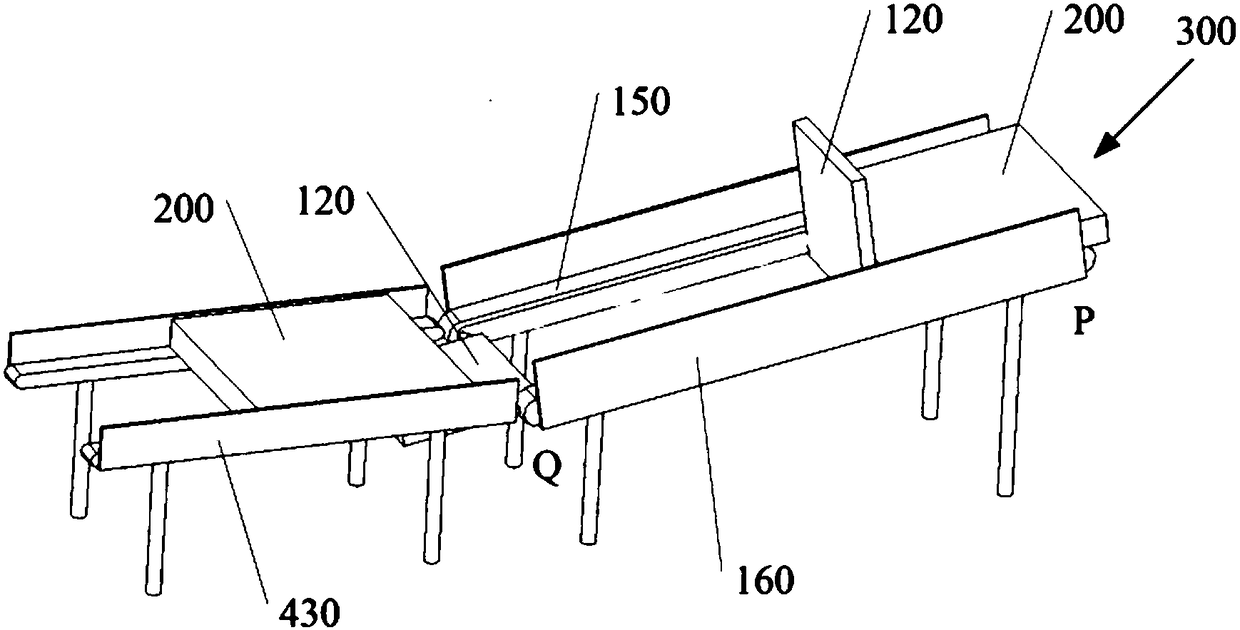

[0047] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 2, the only difference is:

[0048] In the automatic unloading device for conveying battery sheets in this embodiment, the input end of the second conveyor belt 420 is docked with the output end of the first conveyor belt 150, and there is a certain distance between them; the edge of the turning stopper 120 The length in the conveying direction is smaller than the docking distance and greater than the thickness of the stacked battery sheets 200 , and the length of the battery sheets 200 along the conveying direction is greater than the docking distance.

[0049] The turning block 120 in this embodiment is relatively short in length, and directly passes through the butt joint distance between the input end of the second conveyor belt 420 and the output end of the first conveyor belt 150 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com