Pretreatment device for methomyl manufacturing wastewater

A pretreatment device and technology for producing wastewater, applied in water/sewage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of large-scale promotion without utilization, high energy consumption, high equipment cost, etc. Achieve the effect of strong practicability, low energy consumption and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

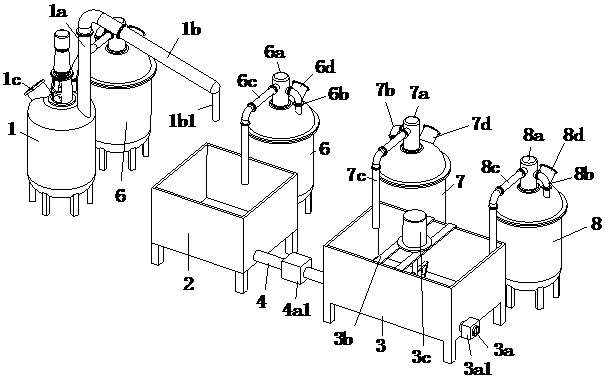

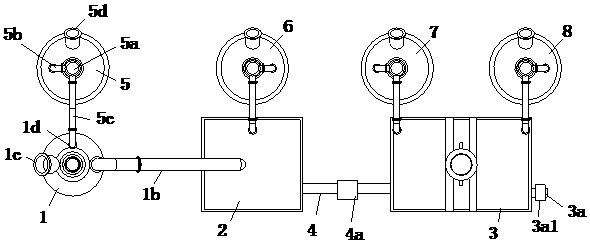

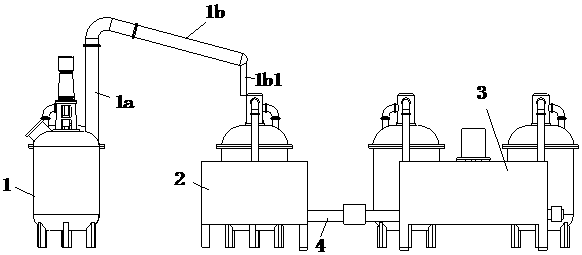

[0020] refer to Figure 1 to Figure 3 A pretreatment device for wastewater produced by methomyl is shown, including an electric heating reactor 1, an alkali hydrolysis tank 2 and an aeration tank 3, and the top of the electric heating reactor 1 is provided with a vertically upwardly arranged first pipeline 1a, the top of the first pipeline 1a is connected with a condensation pipe 1b, the condensation pipe 1b is inclined to the direction of the alkaline hydrolysis tank 2 and is arranged downward, the bottom end of the condensation pipe 1b is provided with a drip tube 1b1, and the drip tube 1b1 is located in the alkaline hydrolysis tank 2, the alkaline hydrolysis tank 2 and the aeration tank 3 are set with an open top, and the alkaline hydrolysis tank 2 and the aeration tank 3 are communicated through the second pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com