Tunnel waterproof material laying device

A waterproof material and laying device technology, which is applied in the direction of tunnels, tunnel linings, mining equipment, etc., can solve problems such as difficulty in meeting construction progress and construction quality, large error in manual lap joint size, and long construction time, so that it is not easy to loosen or Effects of drop, efficiency improvement, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

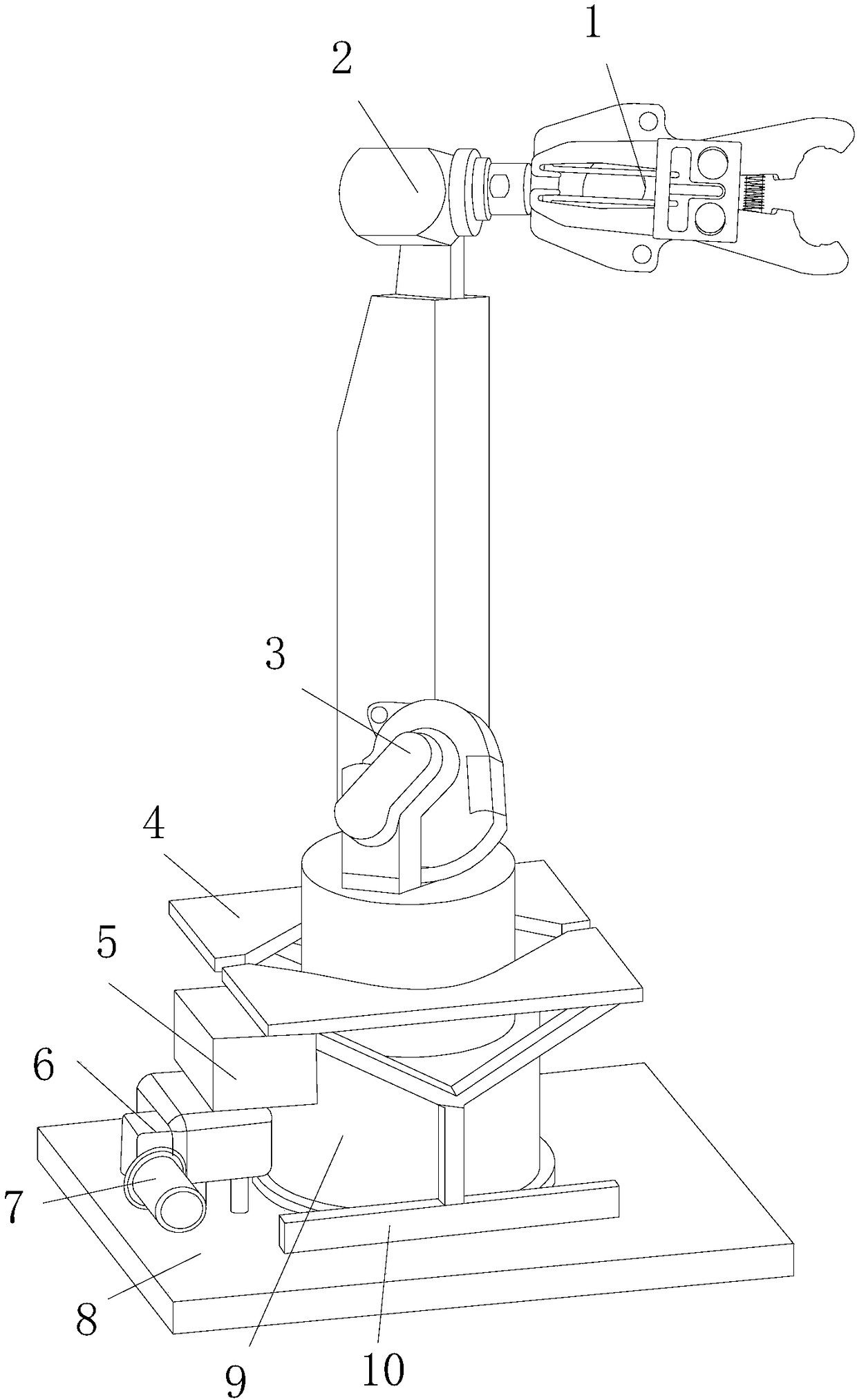

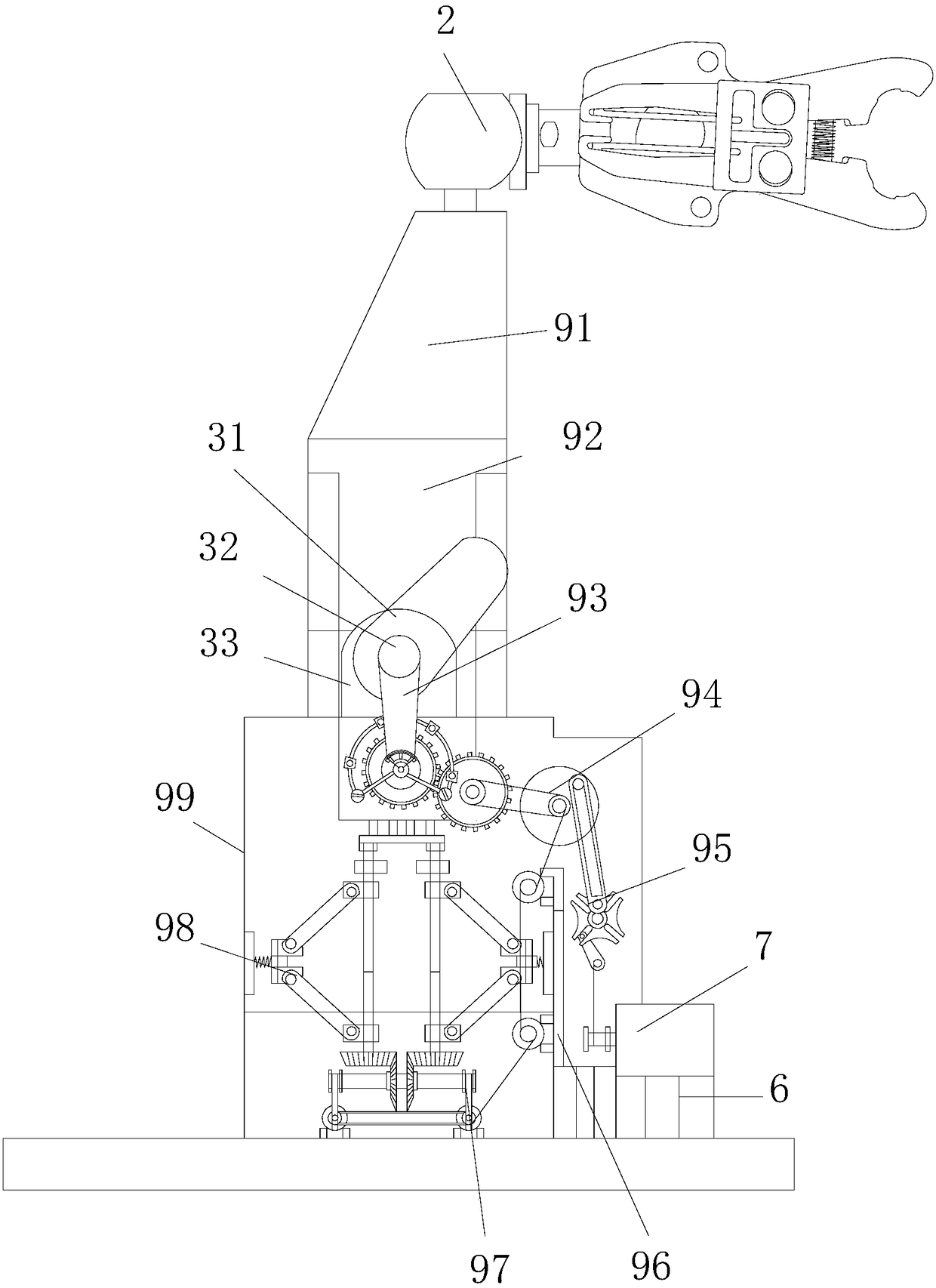

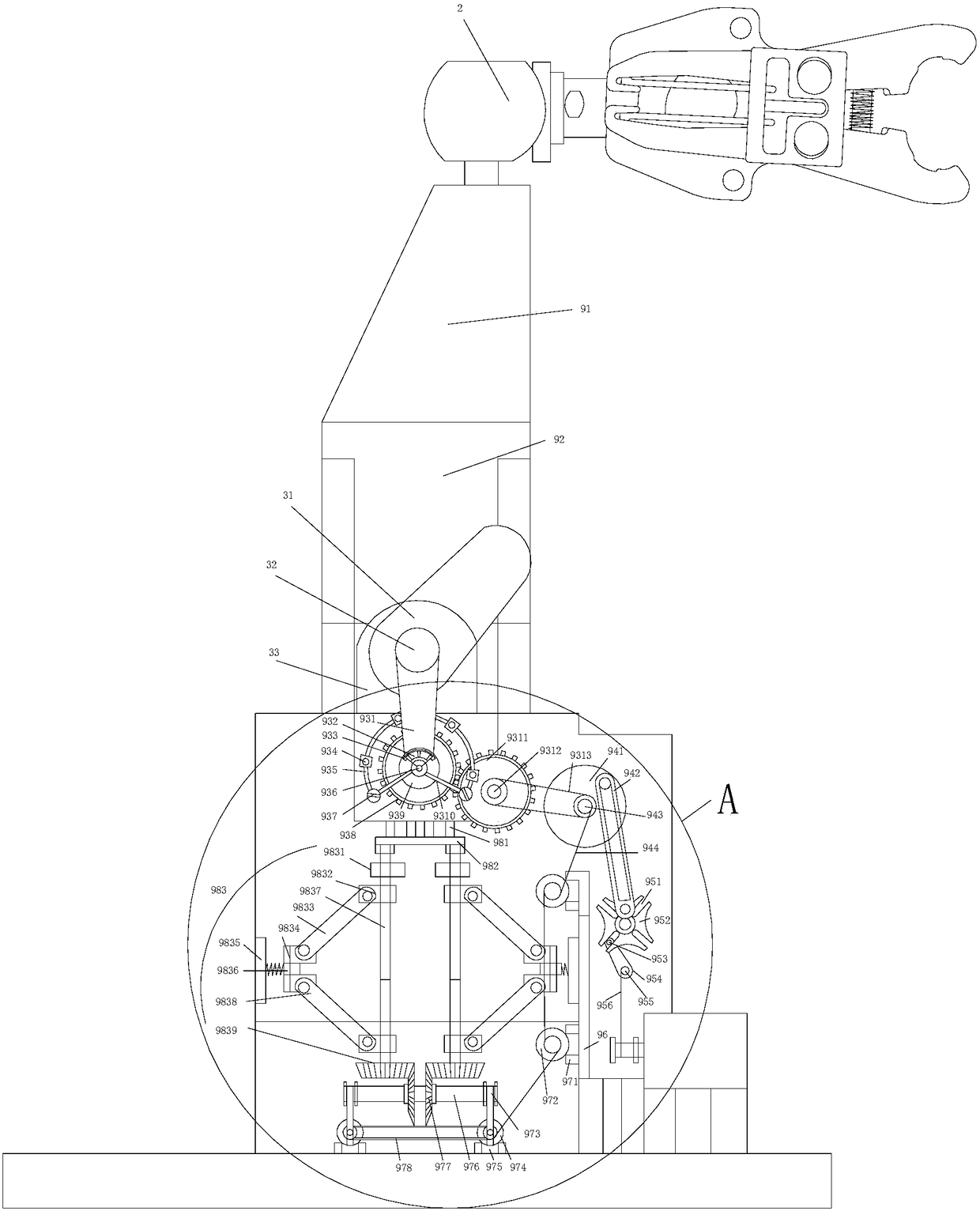

[0025] see Figure 1-Figure 4 , The present invention provides a tunnel waterproof material laying device, the structure of which includes a clamping manipulator 1, a mounting head 2, a rotating head 3, a splint 4, a small shell 5, a bracket 6, a motor 7, a bottom plate 8, a lifting and rotating system 9, Underframe 10, the bottom plate 8 is provided with a lifting and rotating system 9 in the middle, and a splint 4 is sandwiched at one-third of the lifting and rotating system 9, and the splint 4 is fixed on the bottom plate 8 through the underframe 10 A small housing 5 is arranged next to the lifting and rotating system 9, and the small housing 5 is fixed on the bottom plate 8 through the vertical bottom plate 8 of the bracket 6. The lifting and rotating system 9 is mechanically connected with the motor 7, and the The top of the lifting and rotating system 9 is provided with a rotating head 3, the rotating head 3 cooperates with the lifting and rotating system 9, and the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com