Novel hydraulic strain clamp

A tension-resistant clamp and hydraulic technology, which is applied in the direction of adjusting/maintaining mechanical tension, can solve the problems of poor electrical connection between the drainage clamp and the pipe body, unfavorable long-term stable operation of the power supply line, and affecting the quality of the electrical connection, so as to prevent sand Dust enters the contact surface of the fittings, reduces the duration of acid rain, and has the effect of large contact area of the fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

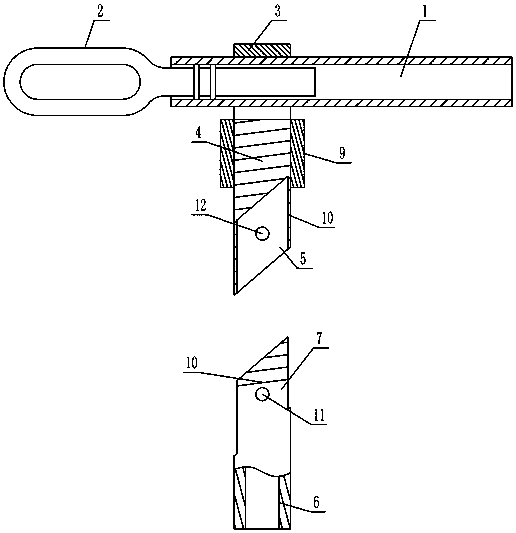

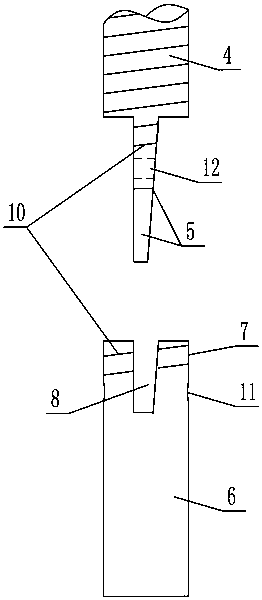

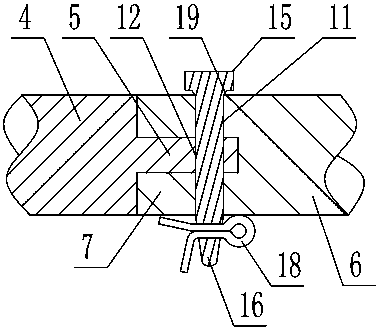

[0033] As shown in the figure, the new hydraulic tension clamp includes a pipe body 1, a steel anchor 2 is inserted at one end of the pipe body 1, and the outer periphery of the pipe body 1 is fixed with a vertically downward drainage stud 4 through a fixing sleeve 3. The lower end surface of the drainage stud is an inclined plane 01 arranged obliquely relative to the axial direction of the drainage stud. The end of the drainage stud 4 is fixed with a vertically arranged inserting plate 5. The inserting plate 5 is a metal plate with a parallelogram shape. The plate 5 includes an upper end surface corresponding to the inclined surface 01, a lower end surface 02 facing downwards, a front plate surface 03 and a rear plate surface 04 with the largest area, and a left side extending downwards corresponding to the arc-shaped outer wall of the drainage stud 4. The arc surface 05 and the right arc surface 06 have six board surfaces, the left arc surface and the right arc surface are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com