Single-stand-column automatic stereoscopic warehouse stacker

A technology of three-dimensional warehouse and stacker, which is applied in the field of mechanical equipment, and can solve the problems of late stacker and the overall performance of the stacker to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described through the following examples, which are only used to explain the present invention and will not constitute any limitation to the present invention.

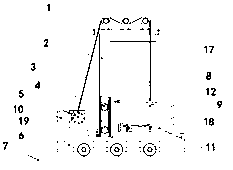

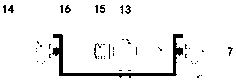

[0015] Attached below Figure 1-2 Describe the embodiment of a single column automatic three-dimensional warehouse stacker of the present invention, including a fixed pulley (1), a column (2), a steel wire rope (3), a guide wheel (4), a lifting mechanism (5), and a horizontal walking mechanism (6), steel rail (7), lifting box (8), storage and retrieval mechanism (9), first motor (10), fork (11), second motor (12) main shaft (13), active steel wheel (14), the third electric motor (15), sprocket wheel (16), first distance sensor (17), second distance sensor (18), electric control cabinet (19).

[0016] Preferably, the horizontal traveling mechanism (6) is installed on the rail (7), the column (2) is installed in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com