Automatic bale plucker

A cotton picking machine and automatic technology, which is applied in the textile field, can solve the problems of no humidity detector, inability to effectively reduce the moisture of cotton raw materials, and no conveyors, etc., to avoid low cotton picking efficiency, fast and convenient cotton raw materials, The effect of fast and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

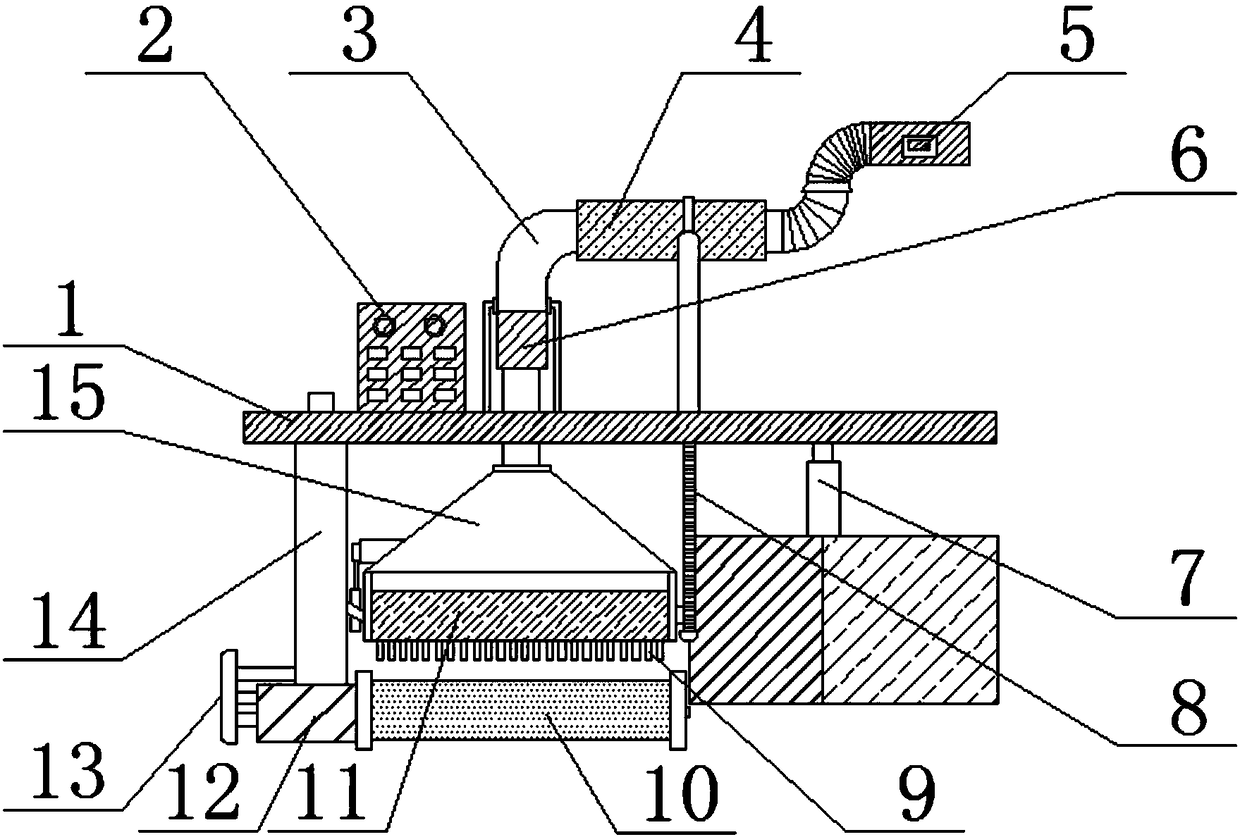

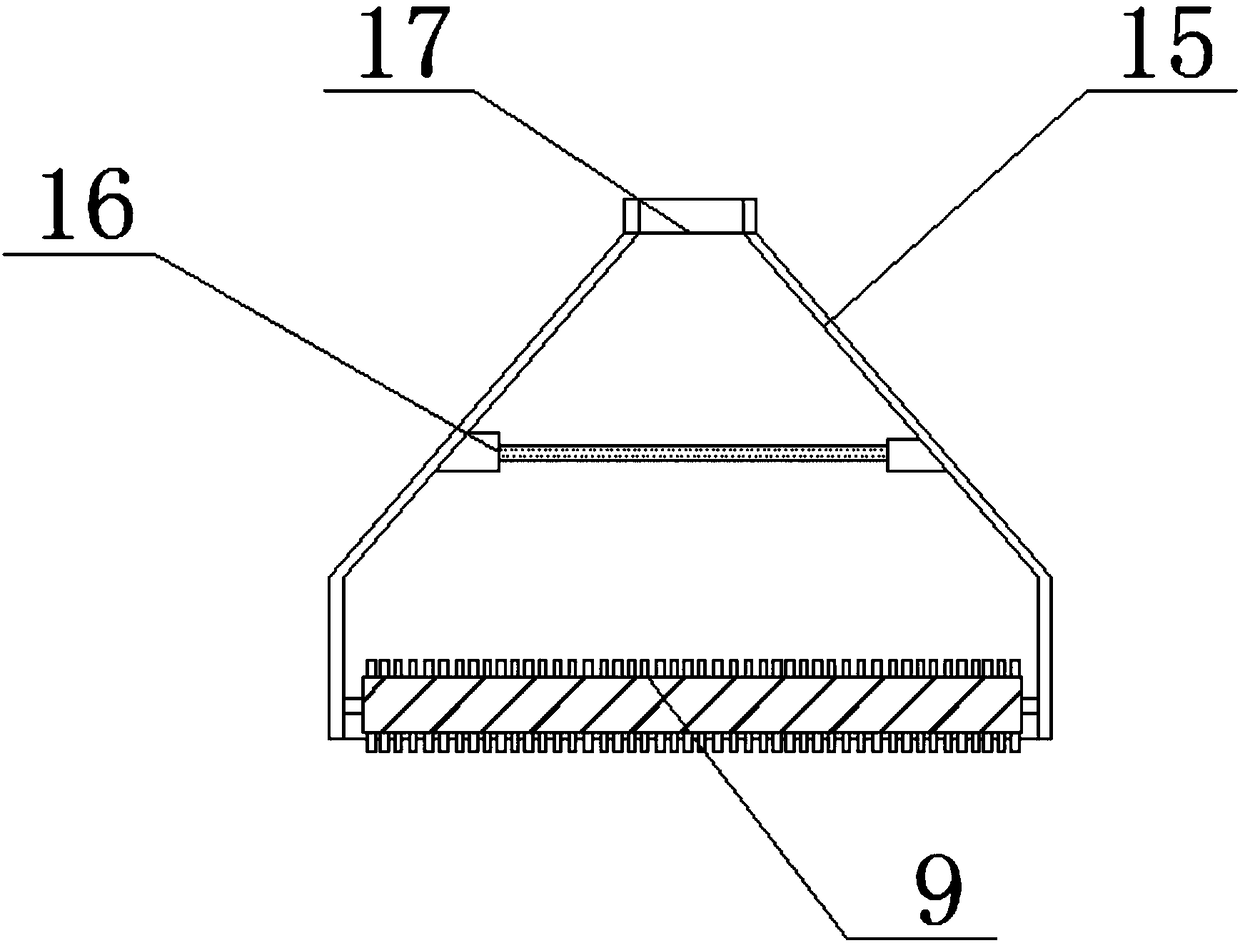

[0020] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, an automatic plucking machine, comprising a support platform 1, the upper end of the support platform 1 is provided with a control switch 2, and the lower end of the support platform 1 is provided with a bracket 14, and one part of the control switch 2 The side is provided with telescopic pipe 6, and the upper end of telescopic pipe 6 is connected with cotton delivery pipe 3, and the lower end of telescopic pipe 6 is connected with grasping cotton hopper 15, and one end of cotton transportation pipe 3 is provided with heating pipe 4, and one side of heating pipe 4 A humidity detector 5 is provided, a beater 11 is arranged at the lower end of the cotton catching hopper 15, and a screw 8 is arranged on one side of the cotton catching hopper 15, a rib 9 is arranged inside the beater 11, and a conveyor 10 is installed below the beater 11 One side of the screw rod 8 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com