Hot air type asphalt pavement heating device for thermal regeneration of old asphalt pavement

A technology for asphalt pavement and heating equipment, which is used in roads, roads, road repair and other directions, can solve the problems of damage, complex structure and high cost, and achieve the effects of reducing production costs, prolonging mixing time, and reducing thermal insulation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

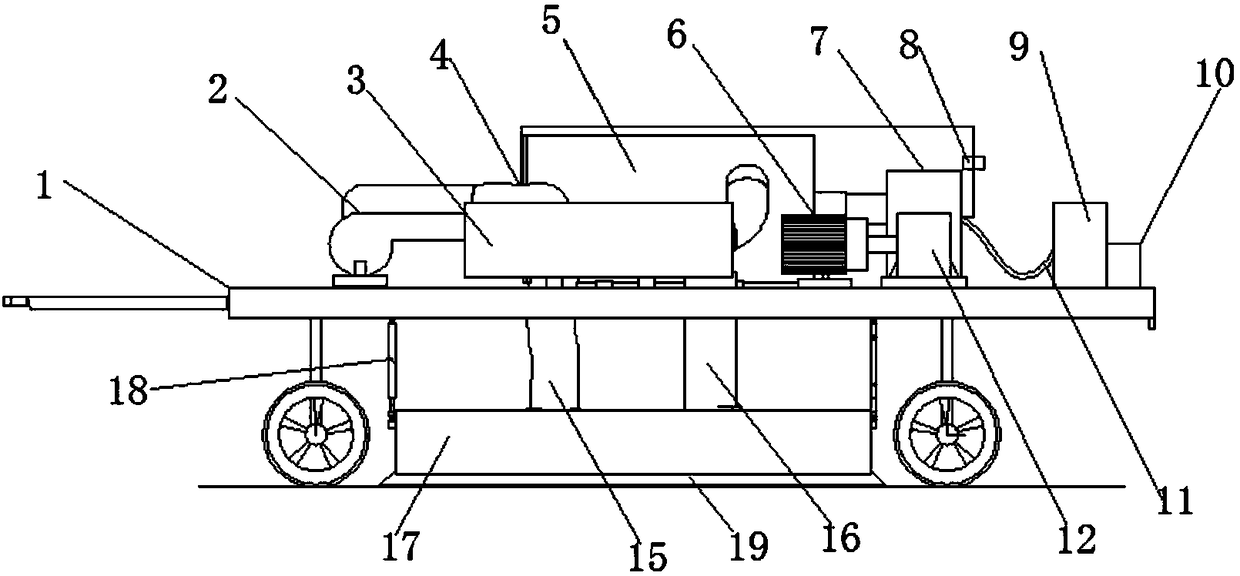

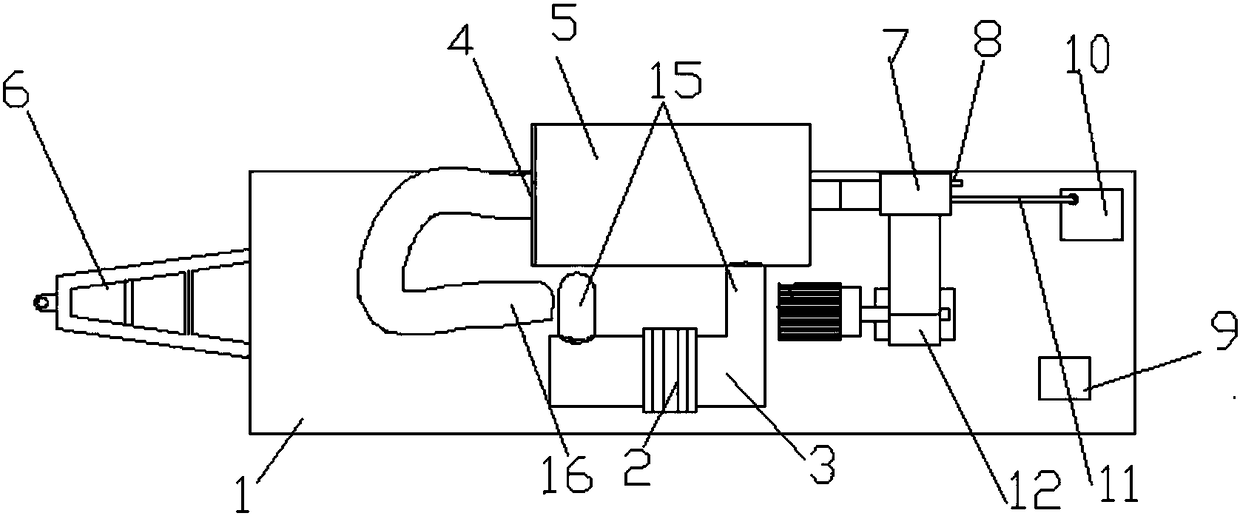

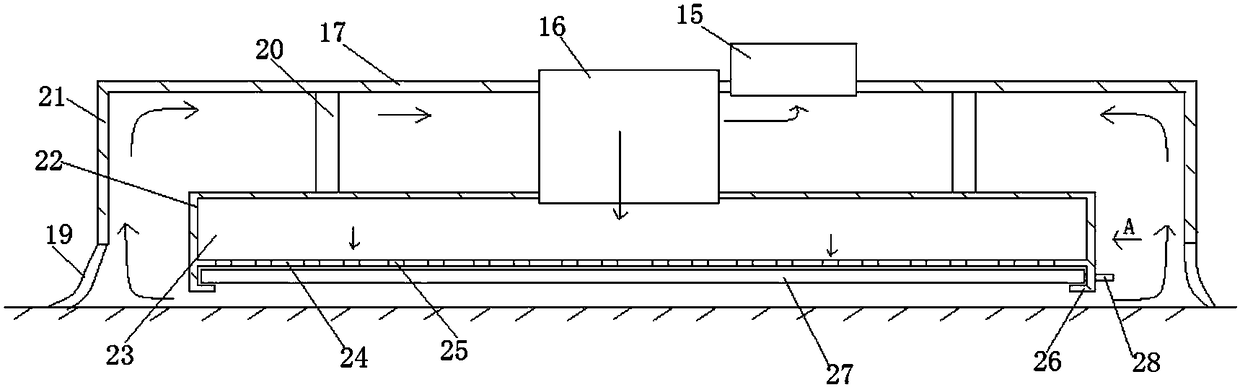

[0027] Such as Figure 1 to Figure 7 As shown, the present invention discloses a hot air type asphalt pavement heating equipment for thermal regeneration of old asphalt pavement, including a chassis vehicle 1, a hot air generating device is installed on the chassis vehicle 1, and the hot air generating device includes a For heating the air to generate the hot blast stove 5 of hot blast; the bottom of the chassis vehicle 1 is movably equipped with a bottomless hot blast cover 17, and the hot blast cover 17 is provided with the first air outlet hole 25 for delivering hot blast to the ground, The hot blast stove 5 provides hot blast to the first air outlet 25 through the hot blast delivery pipe 16; the wind shield 19 that can contact the ground is arranged around the hot blast cover 17, and the hot blast cover 17 is connected to the hot blast stove 5 through a hot blast recovery pipe 15 .

[0028] Chassis vehicle 1 among the present invention can be powered vehicle or unpowered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com