Mounting and lifting method for movable formwork for bridge construction

A mobile formwork and bridge construction technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that the mobile formwork cannot be installed economically and effectively, and it is difficult to install, and achieves high construction efficiency, time saving and high efficiency. cost, effectiveness of avoiding security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

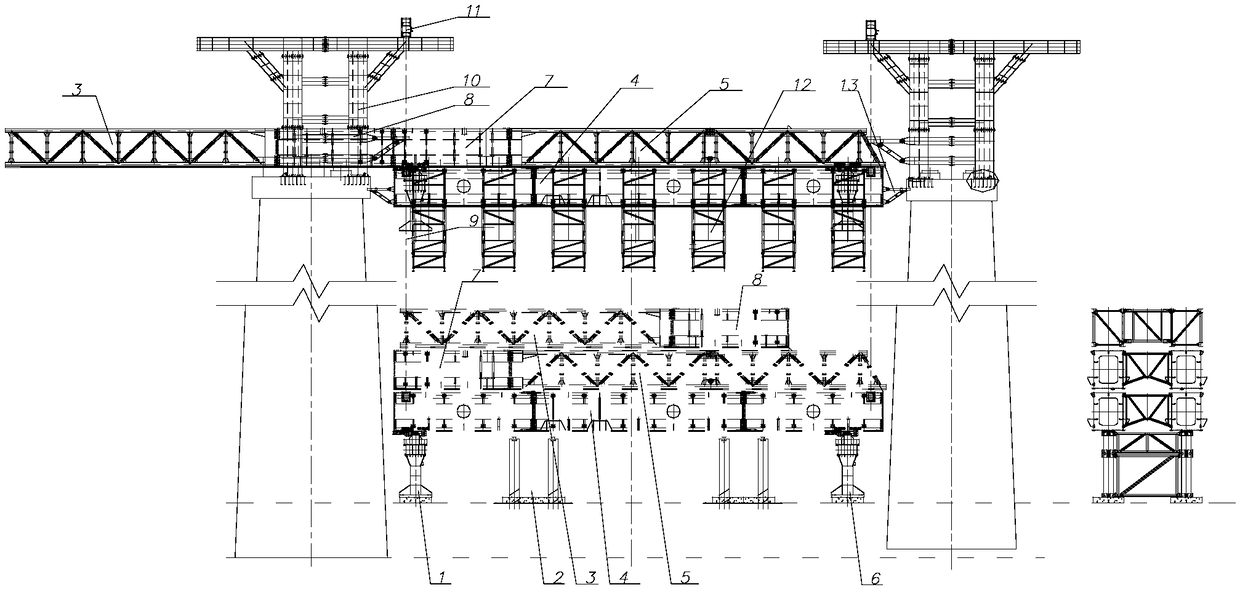

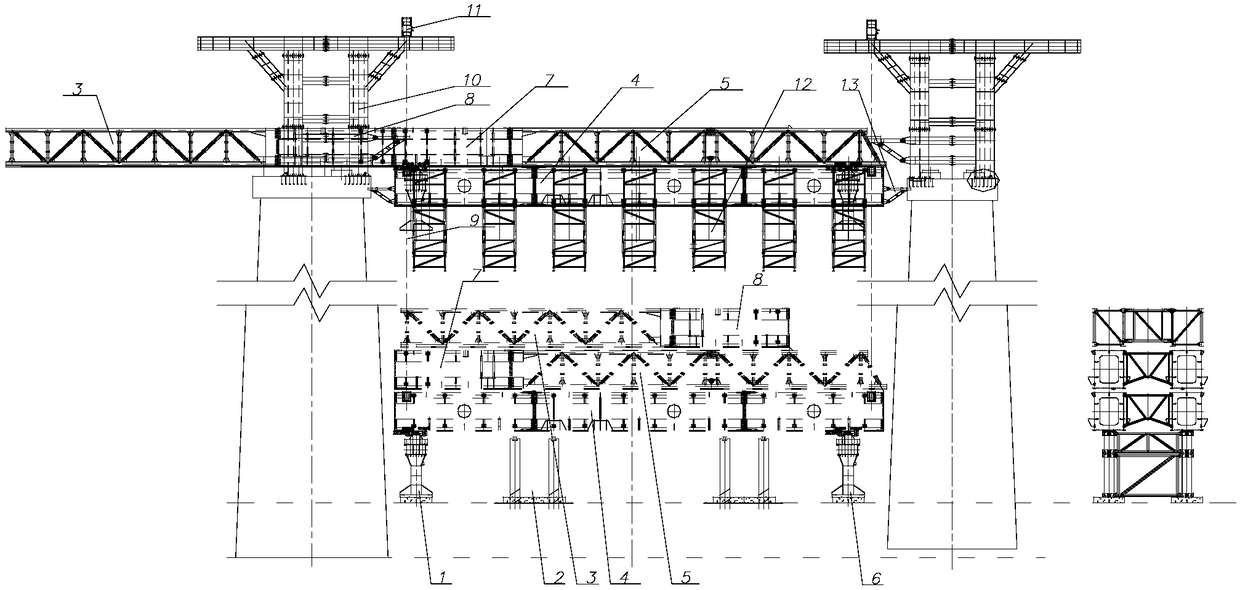

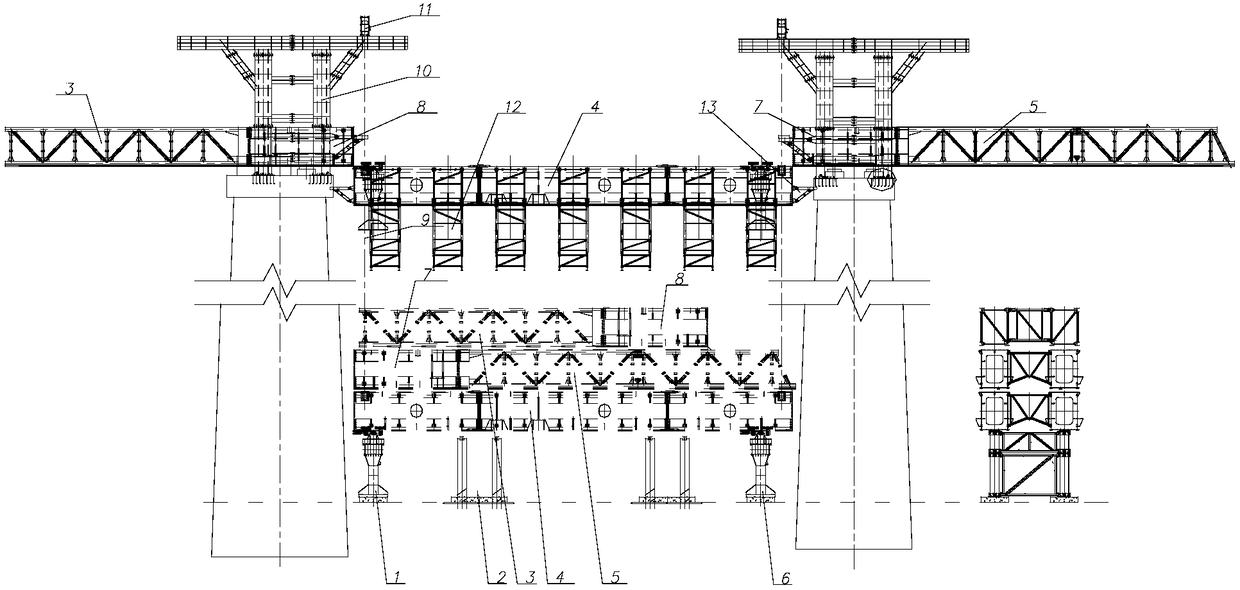

[0020] Please also see figure 1 , figure 2 , image 3 and Figure 4 , the installation and lifting method of the mobile formwork for bridge construction is a method for bridge construction for the mobile formwork. The mobile formwork includes rear main legs 1, rear guide beam 3, main beam 4, front guide beam 5, front main support Leg 6, main beam head connecting section 7, main beam tail connecting section 8, hanging outer rib 12, outer mold system and inner mold system, and stabilizer struts 13 are equipped on both sides of the main girder 4, and the stabilizer struts 13 can be stretched laterally The support rod of the stabilizing strut 13 is an oil cylinder piston rod, and the cylinder barrel of the oil cylinder piston rod is fixedly fitted on the front end and the rear end of the girder 4, and the rod end of the oil cylinder piston cylinder is used to support the pier body of the pier, stabilizing the support The effect of bar 13 is mainly used for stably supporting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com