Shallow soft-base soil curing technology and system

A curing process and soft foundation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of perishable and odorous pollutants, foul odor of cured soil, and increased construction steps, so as to achieve good curing effect, The effect of simplifying curing construction procedures and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

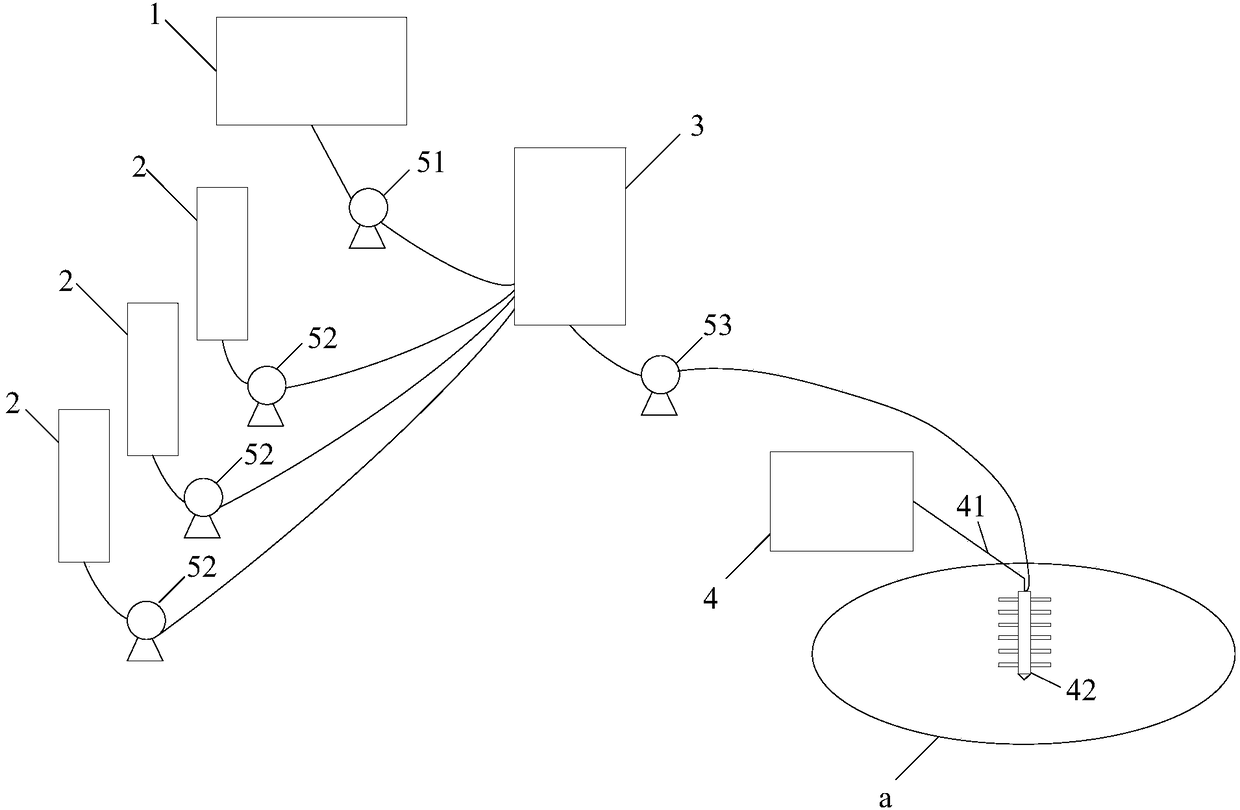

[0046] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] The shallow soft soil solidification process and the shallow soft soil solidification system of the present invention will be described in detail below through examples.

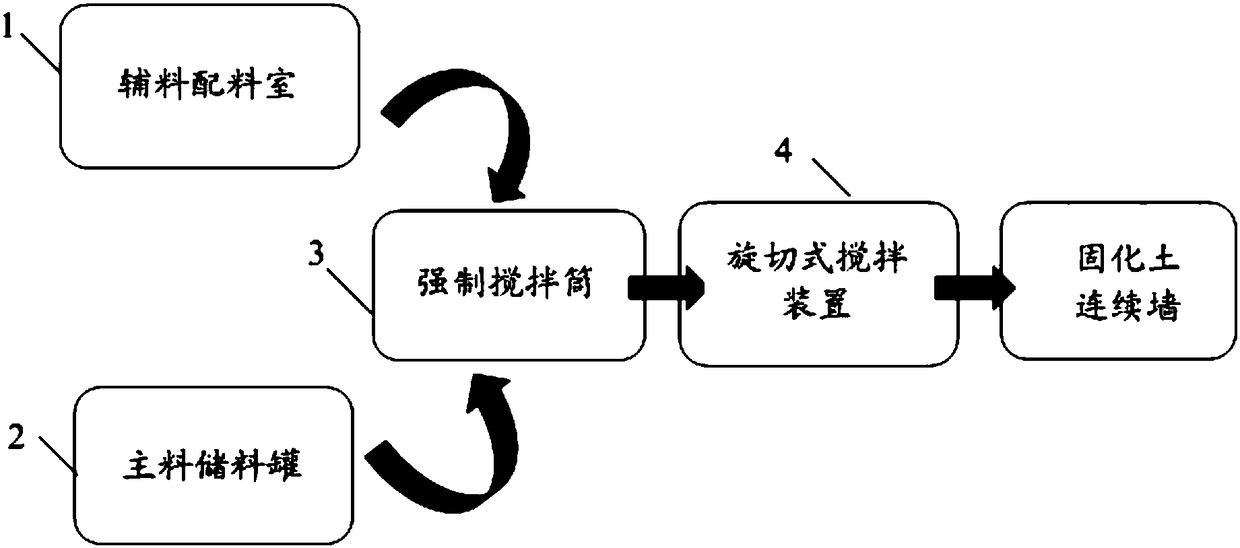

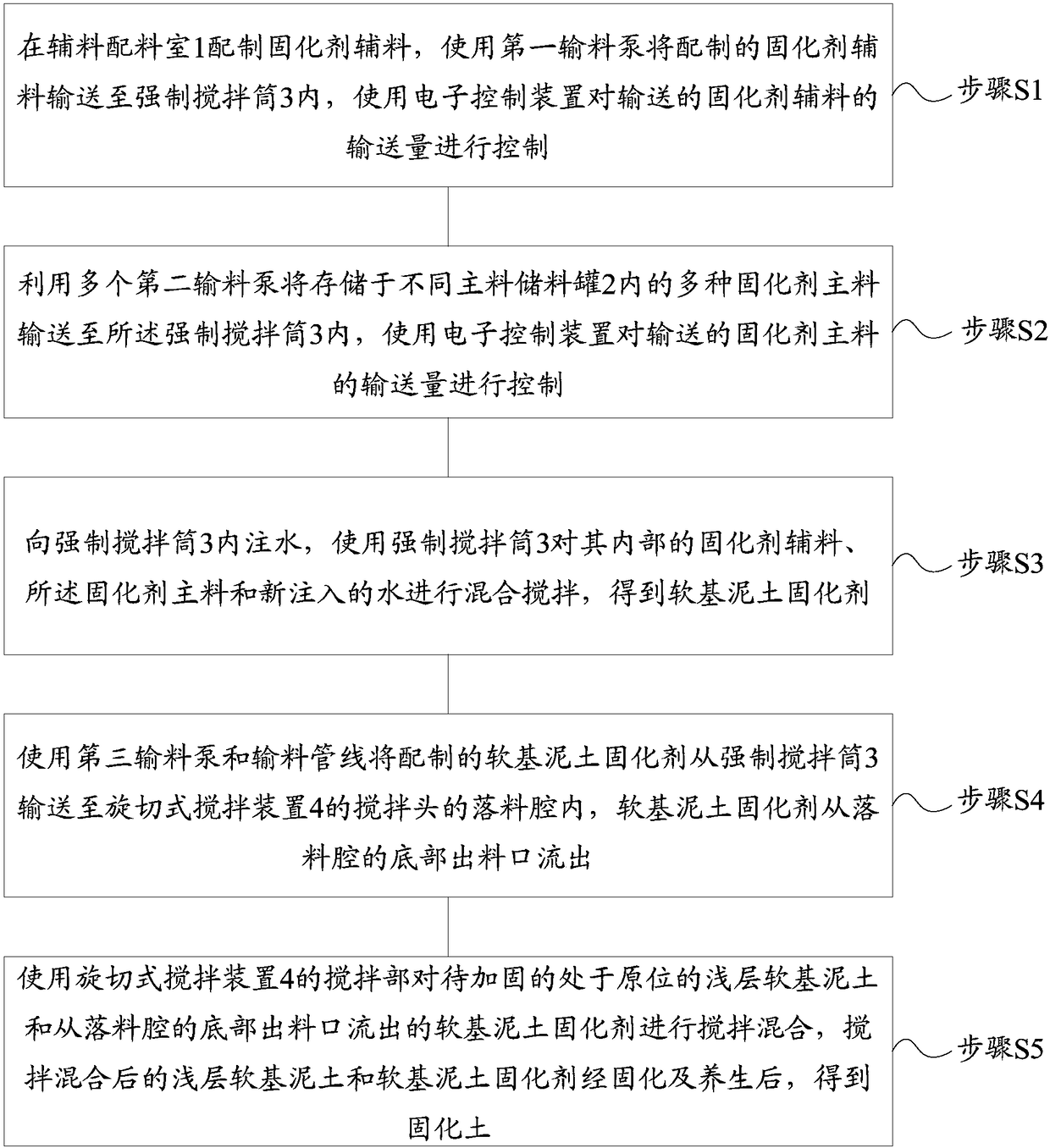

[0048]The embodiment of the present invention provides a shallow soft soil solidification process, which can be used to solidify the shallow soft soil, for example, to solidify the shallow soft soil with a depth of 0-2m.

[0049] Soft foundation soil can include many kinds, such as soft foundation sludge, soft foundation silt and so on. Soft base sludge is produced during the treatment of domestic water and industrial wastewater, such as the sludge produced during the treatment of chemical wastewater. Soft foundation silt is formed by depositing in river...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com