Sandwich type prefabricated concrete inner wallboard structure, manufacture and assembly method

A precast concrete and concrete interior technology, applied to walls, building components, building structures, etc., can solve the problems of large area of precast concrete inner wall panels, inconvenient transportation and hoisting, unfavorable large-scale production, etc., to achieve convenient mass production and Transportation and storage, thermal insulation and sound insulation performance are good, and the effect of promoting recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] like Figure 1-Figure 15 As shown, the sandwich type prefabricated concrete inner wall panel structure, production and assembly method of the present invention are as follows:

[0039] (1) Structure and manufacturing process of sandwich precast concrete interior wall panels

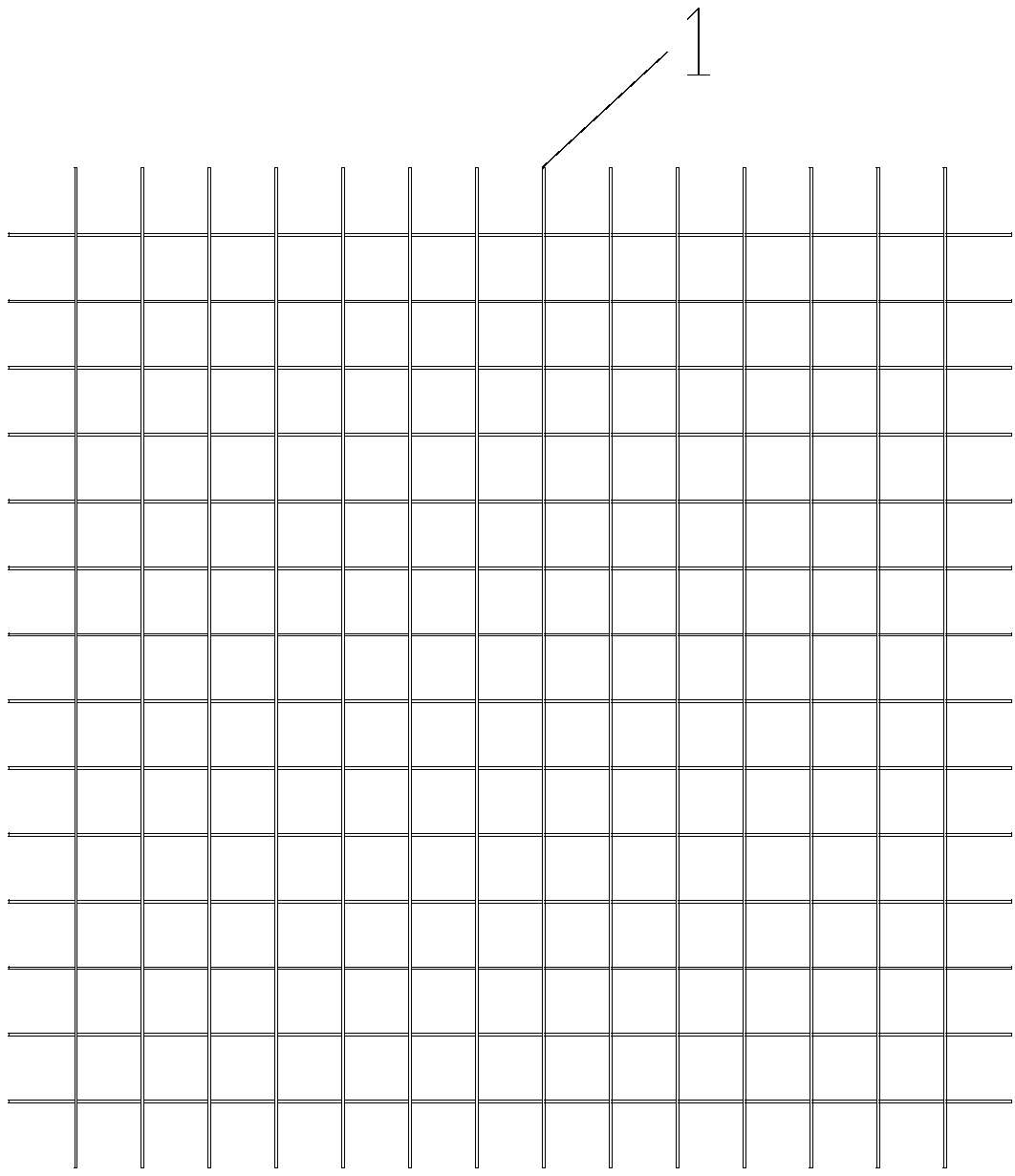

[0040] like figure 1 As shown, the single-layer reinforcement mesh 1 (reinforcement mesh for short) of the concrete inner wall panel is formed by vertically arranging criss-cross thin steel bars with a diameter of 4 mm, and the spacing of the thin steel bars is 150 mm.

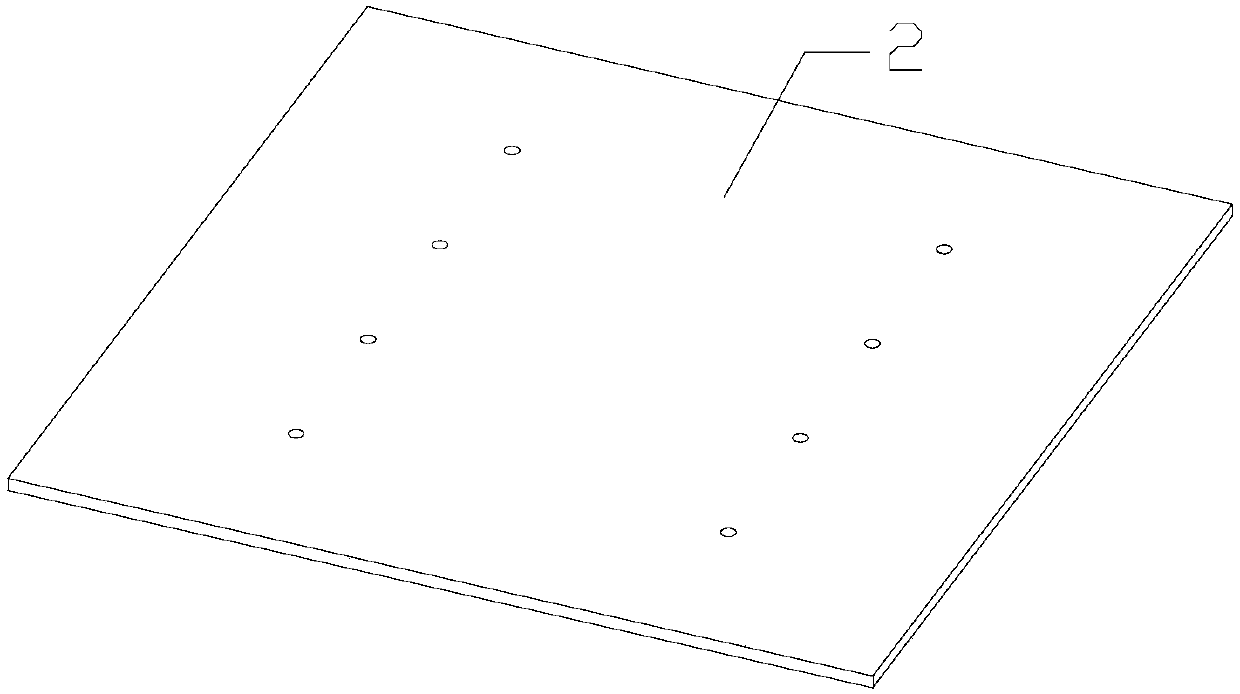

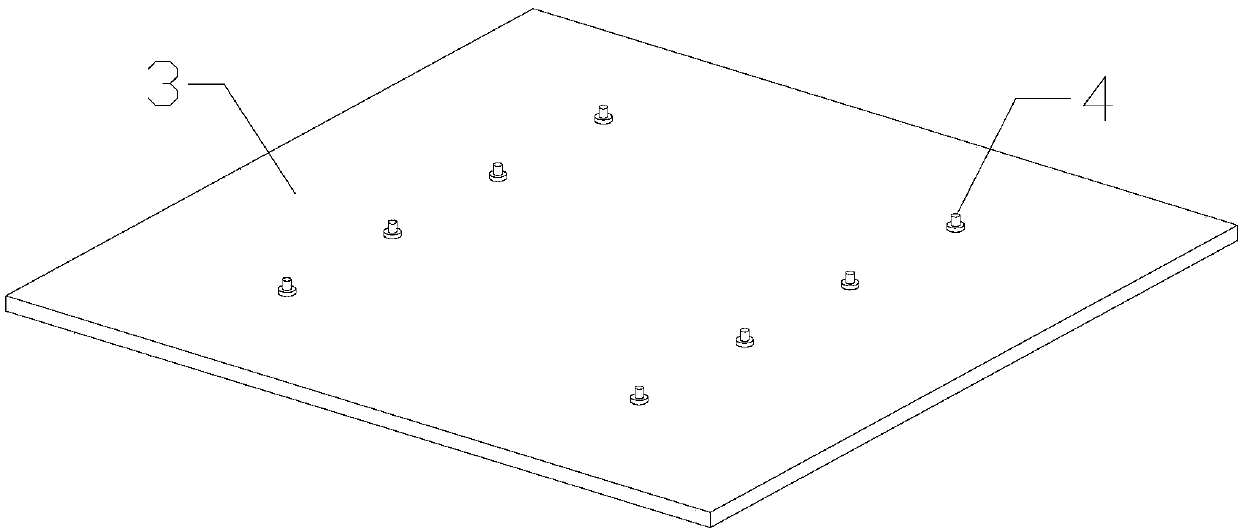

[0041] like Figure 2-Figure 3 As shown, the non-threaded T-screw 4 is welded with the steel plate 2 with holes to form the bottom formwork 3 of the concrete inner wall panel. On the other side of the steel plate 2, the nut is welded to the steel plate with holes 2 through holes, and the welding seam is located in the hole of the steel plate 2 with holes, so as to prevent the weld between the bottom template 3 and the nut from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com