Patents

Literature

62results about How to "Low personnel requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing alginate for fast preparation of hydrogel

The invention provides a method for preparing alginate of hydrogel quickly, which comprises the following steps: 1. the water-soluble alginate is prepared to 0.1 to 1 percent even aqueous solution; 2. soluble divalent metal salt aqueous solution is added with the stirred alginic acid aqueous solution; and after the mixture is dispersed evenly, the mixture is kept stand to react for 10 to 30 minutes so as to generate jelly; 3. the jelly is dehydrated by an organic solvent to the degree that the water content is between 40 and 70 percent; 4. the dehydrated material is dried to the degree that the water content is between 5 and 15 percent; and 5. the dried material is crashed to 80-250 meshes to obtain finished product. The alginate prepared by the method is added with proper amount of water, and the hydrogel product is produced. The use is convenient and quick and the equipment investment is not needed.

Owner:QINGDAO BRIGHT MOON SEAWEED BIO HEALTH TECH GRP CO LTD

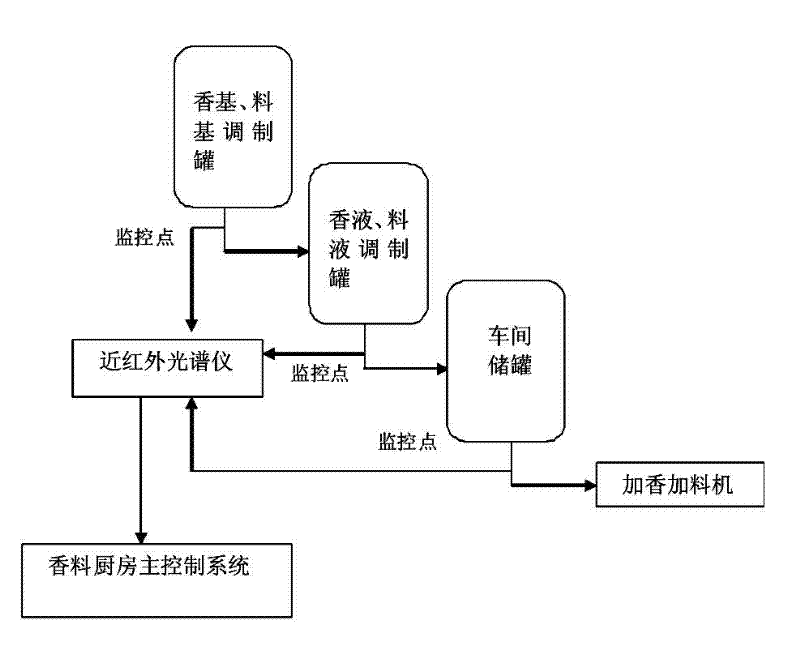

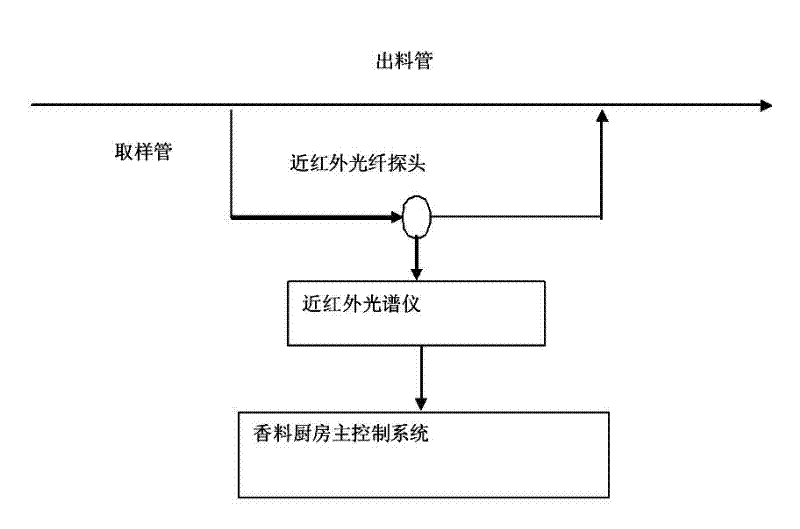

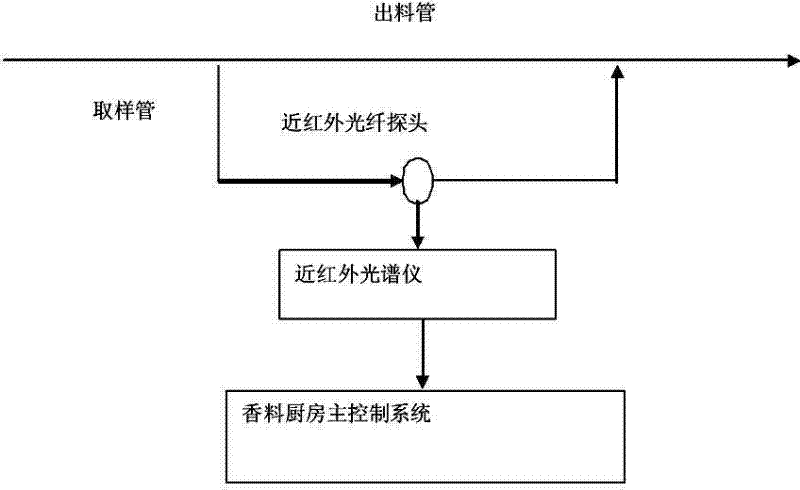

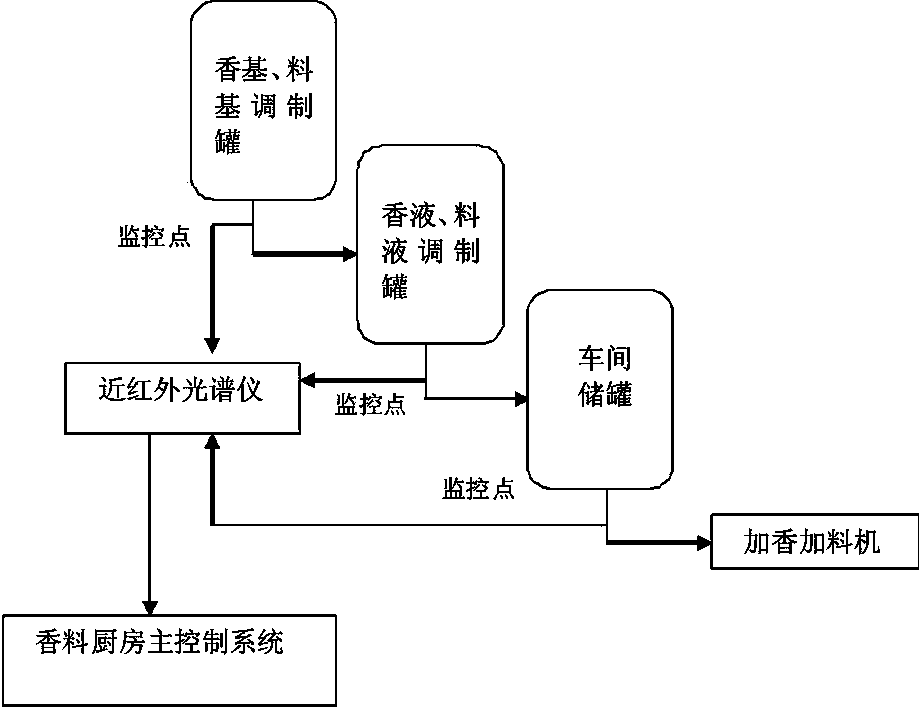

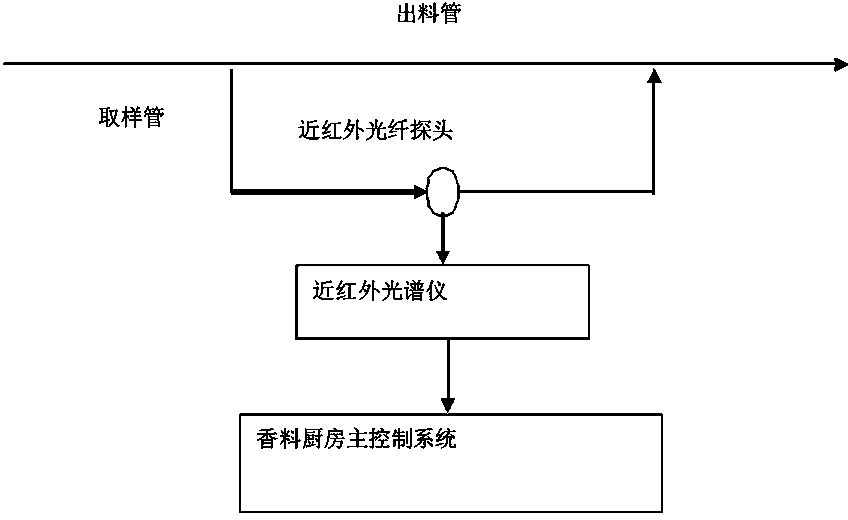

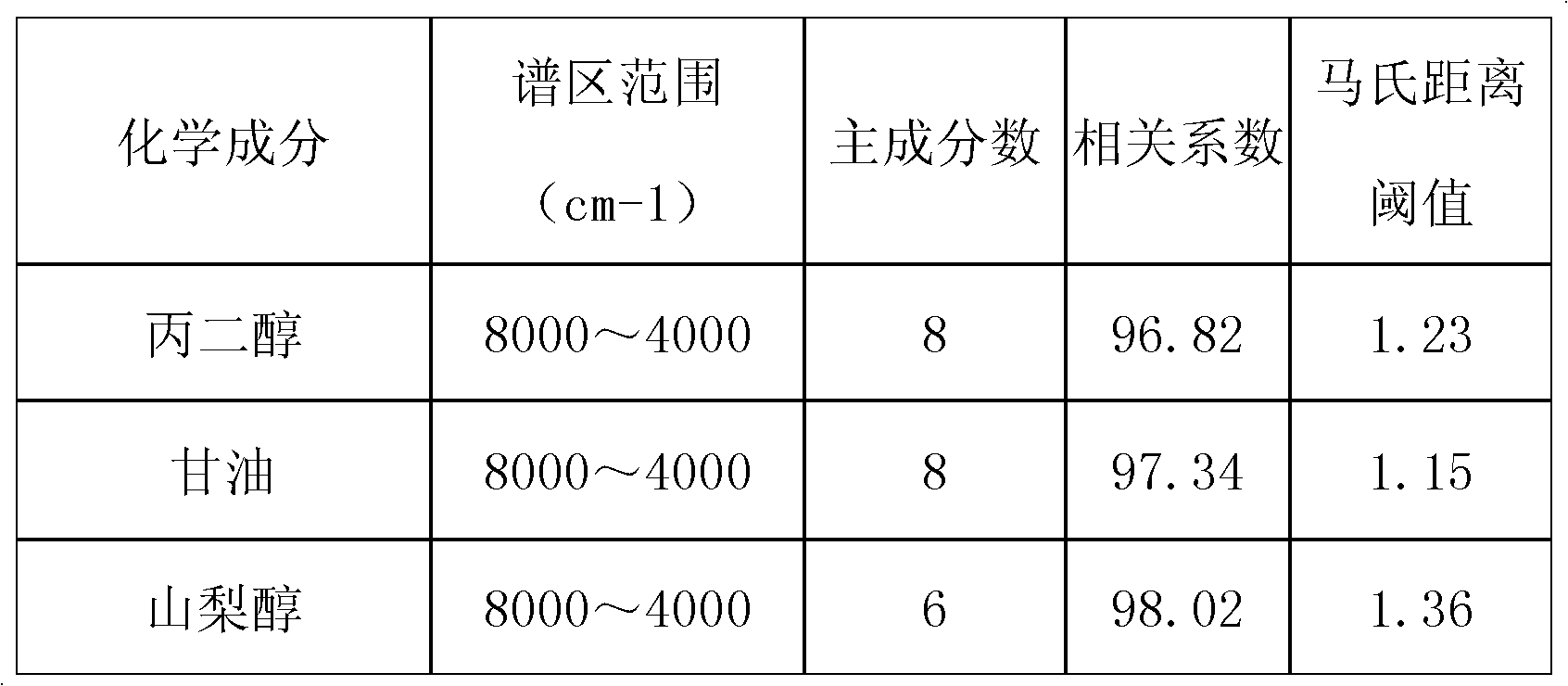

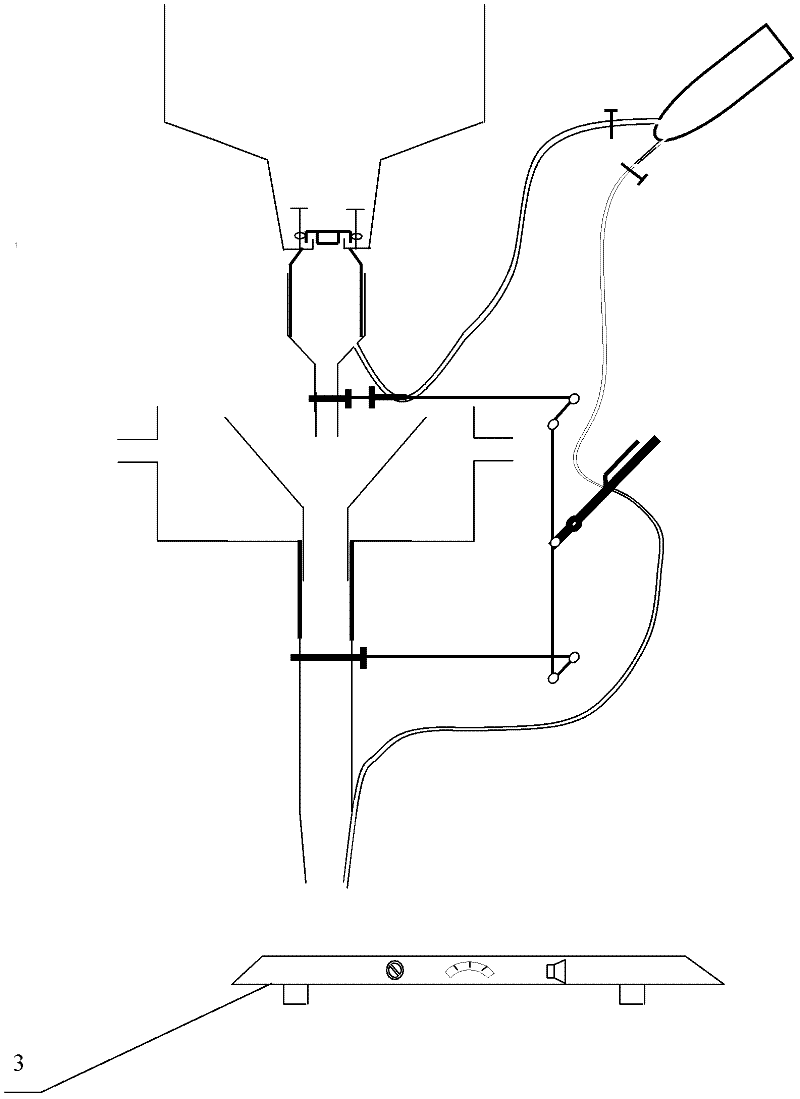

On-line monitoring device and method for preparing tobacco essence perfume

ActiveCN102566533AHigh precisionFast analysisTotal factory controlProgramme total factory controlControl systemMahalanobis distance

The invention discloses an on-line monitoring device for preparing tobacco essence perfume. According to the on-line monitoring device, one or more process monitoring points are provided with sampling pipelines respectively; near infrared optical fiber probes are arranged behind the sampling pipelines respectively; a plurality of near infrared optical fiber probes at different process monitoring points share and are connected with a near infrared spectrometer; and the near infrared spectrometer is connected with a perfume kitchen master control system through a data line. The near infrared spectrum technology is applied to on-line real-time monitoring of the tobacco essence perfume preparation process. After establishing the on-line monitoring device and a model, a quantitative chemical index and a mahalanobis distance of a sample can be obtained in real time by scanning a spectrum of the sample on line and are compared with control requirements; and if abnormity occurs, the master control system alarms to prompt the technical personnel to search the reason.

Owner:CHINA TOBACCO FUJIAN IND

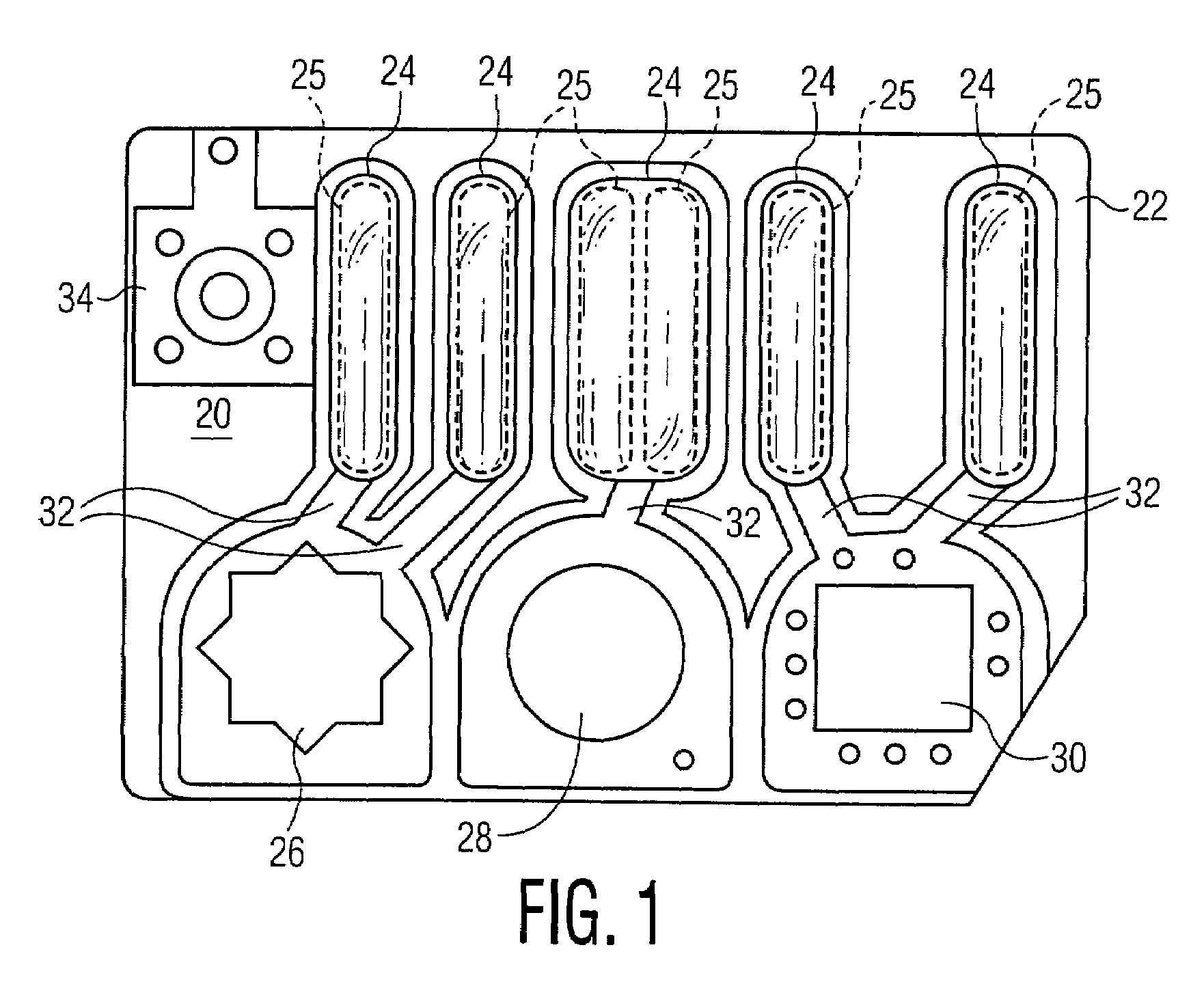

Automated ampoule breaking device

InactiveUS7445753B1Extend the rest timeImprove abilitiesAnalysis using chemical indicatorsLaboratory glasswaresBiomedical engineeringAmpoule

An automated ampoule breaking device includes a carriage having an opening for receiving and securely retaining a substrate in a substantially upright position, wherein the substrate includes at least one flexible compartment each having an outlet at the lower end and at least one ampoule contained therein; and at least one movable projection operatively associated with the carriage, wherein each of the at least one projection adapted for applying sufficient pressure progressing from the upper to the lower end of the corresponding flexible compartment to crush the at least one ampoule and direct the contents of the crushed ampoule out of the respective flexible compartment through the outlet.

Owner:UNITED STATES OF AMERICA

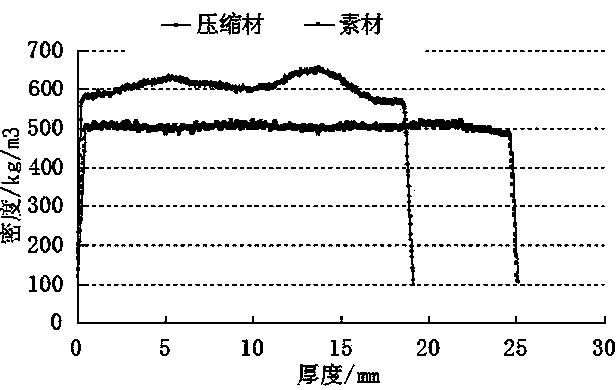

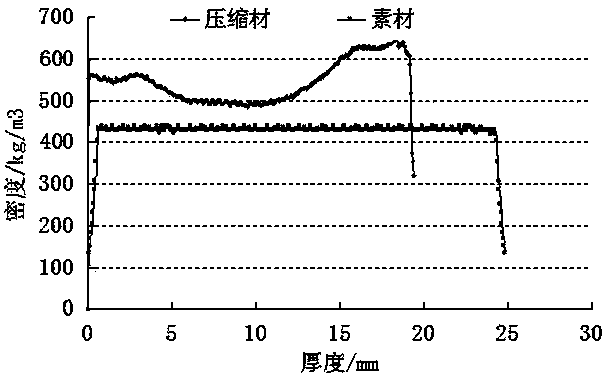

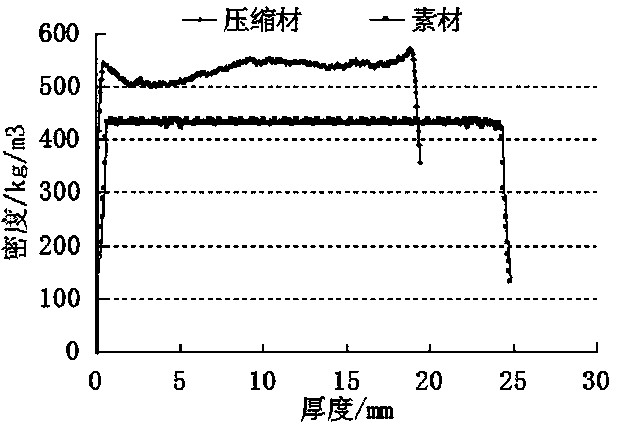

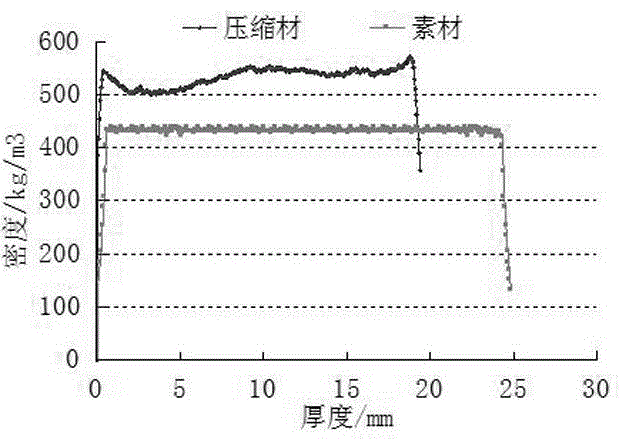

Integral reinforced solid wood section bar and manufacturing method thereof

ActiveCN103481348ASmall volume lossHigh strengthWood working apparatusDomestic articlesSolid woodThermal insulation

The invention belongs to the technical field of function improving and machining of wood and particularly discloses an integral reinforced solid wood section bar and a manufacturing method thereof. The method comprises the steps of under the condition of lower water content (1-3%), adopting a single heating softening molding technology to perform low-compression rate integral compressing treatment on the wood to obtain an integral staypak with the section being uniform in density. According to the method, bursting and bubbling phenomena generated by overhigh steam pressure in the wood can be effectively reduced, the thermal insulation time can be greatly shortened, and the work efficiency is improved. The integral compression wood section bar generated by the method is good in size stability, environment-friendly and healthy, and can be used for manufacturing solid wood floors and solid wood furniture and as indoor decoration materials.

Owner:江门健威家具装饰有限公司

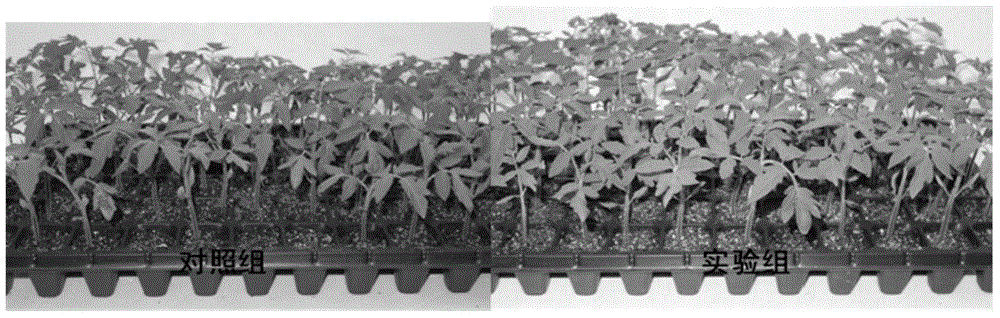

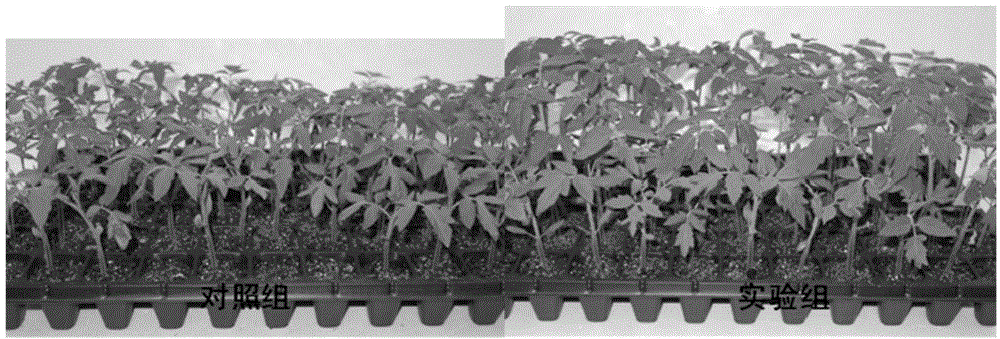

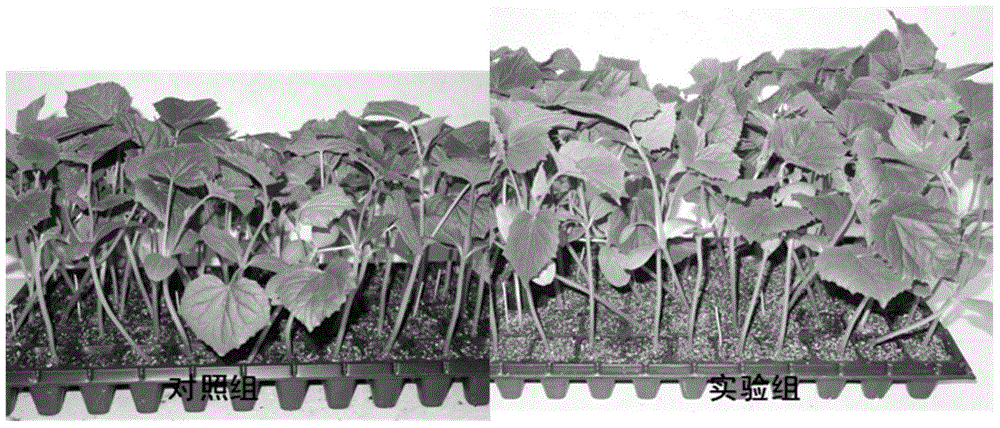

Bacillus amyloliquefaciens, method for preparing solid inoculant thereof and application of solid inoculant

InactiveCN104962492AThe fermentation process is simpleReduce pollutionBiocidePlant growth regulatorsGrowth plantBacillus amyloliquefaciens

The invention relates to bacillus amyloliquefaciens, solid inoculant of the bacillus amyloliquefaciens, a method for preparing the solid inoculant and application of the solid inoculant. The bacillus amyloliquefaciens is kept under CGMCCNO.10045. The bacillus amyloliquefaciens, the solid inoculant, the method and the application have the advantages that a process for fermenting the solid inoculant of the bacillus amyloliquefaciens is simple and is low in environmental pollution and energy consumption, and accordingly the bacillus amyloliquefaciens, the solid inoculant, the method and the application conform to national industrial policies; the solid inoculant of the bacillus amyloliquefaciens has a high effective viable bacterium number and has important application value in the aspect of plant growth promoting and particularly in the aspect of economic plant cultivation.

Owner:CHINA AGRI UNIV

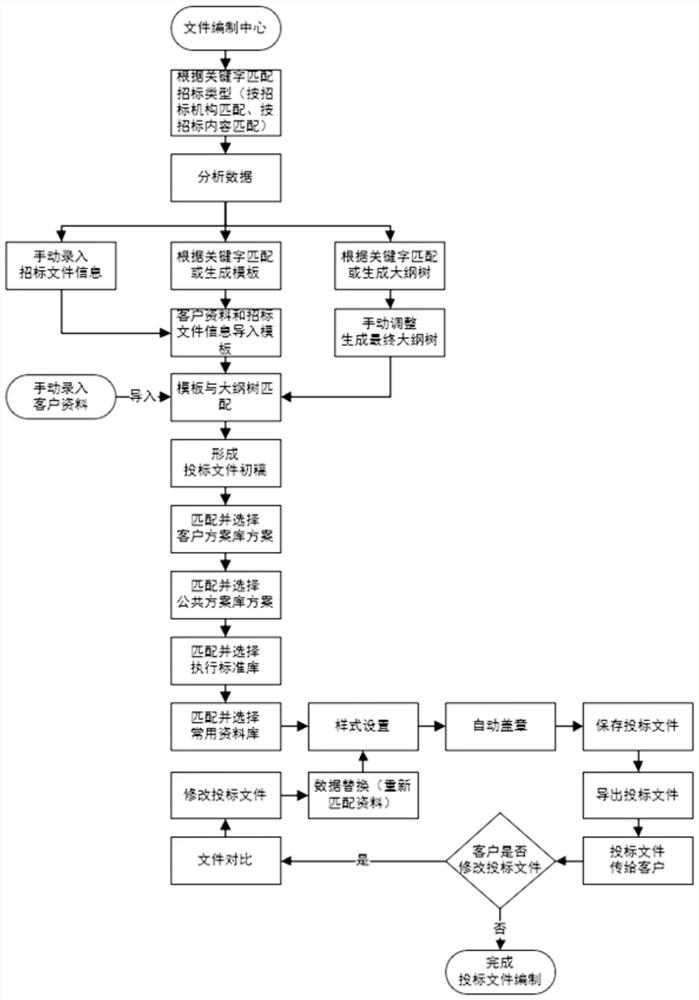

Bidding document automatic generation method, management method, medium and computer

PendingCN112651218AImprove your ability to qualify for winning bidsEasy maintenanceText processingCommerceEngineeringClient data

The invention relates to the technical field of computers, in particular to an automatic bidding document generation method, a management method, a medium and a computer. The generation method comprises steps of keywords being determined according to the content of a bidding document, bidding types being matched according to the keywords, document templates being matched or generated, and outline trees being matched or generated; importing the client data and the bid inviting file information into a document template; matching the document template with the outline tree to form a bidding document first draft; filling and setting the first draft of the bidding file, and then signing to generate the bidding file; confirming the bidding document, and generating a bidding document if the bidding document meets the requirements; if the bidding document does not meet the requirement, modifying the bidding document and re-confirming the bidding document. According to the method, existing bidding documents are carded in a standardized and normalized mode, accumulated bidding document typesetting compilation experience is effectively accumulated and precipitated, a knowledge base is formed, and use of knowledge experience is brought into play; the requirement for personnel outputting high-quality technical bidding documents is greatly lowered, and the competitive power of bidding is improved.

Owner:盘锦丙衡商务服务有限公司

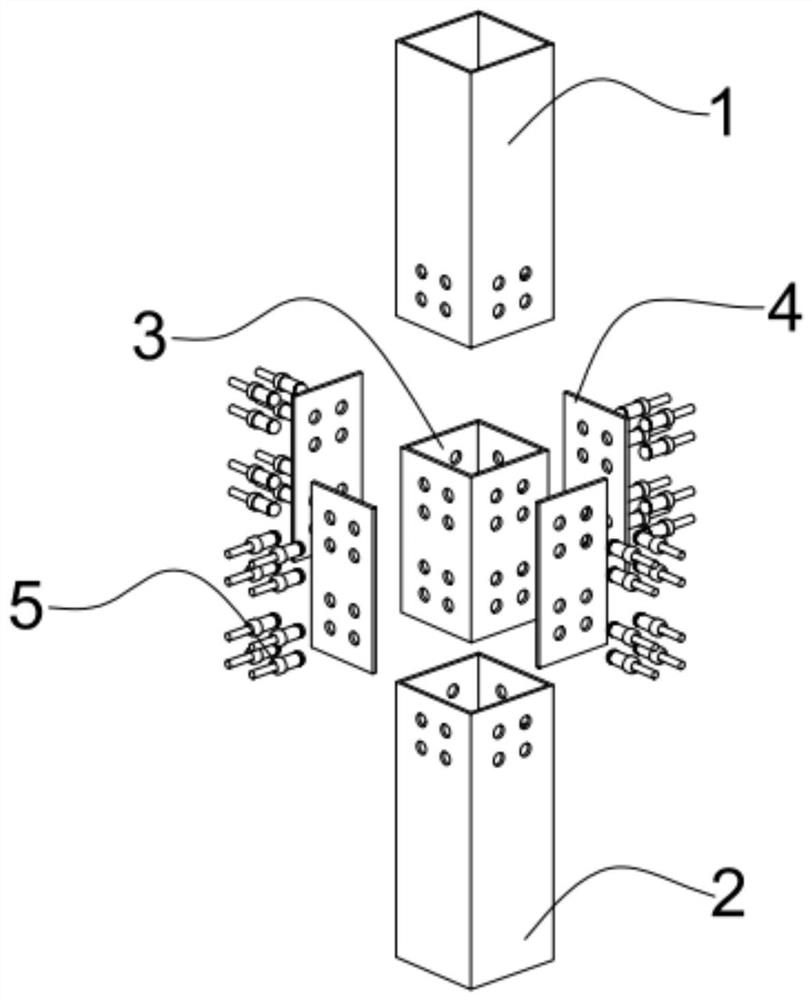

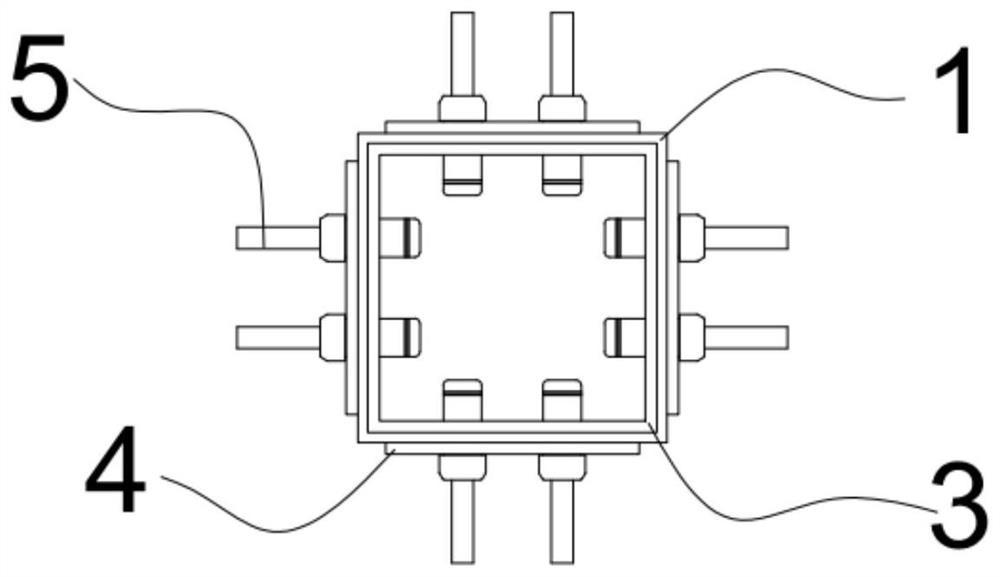

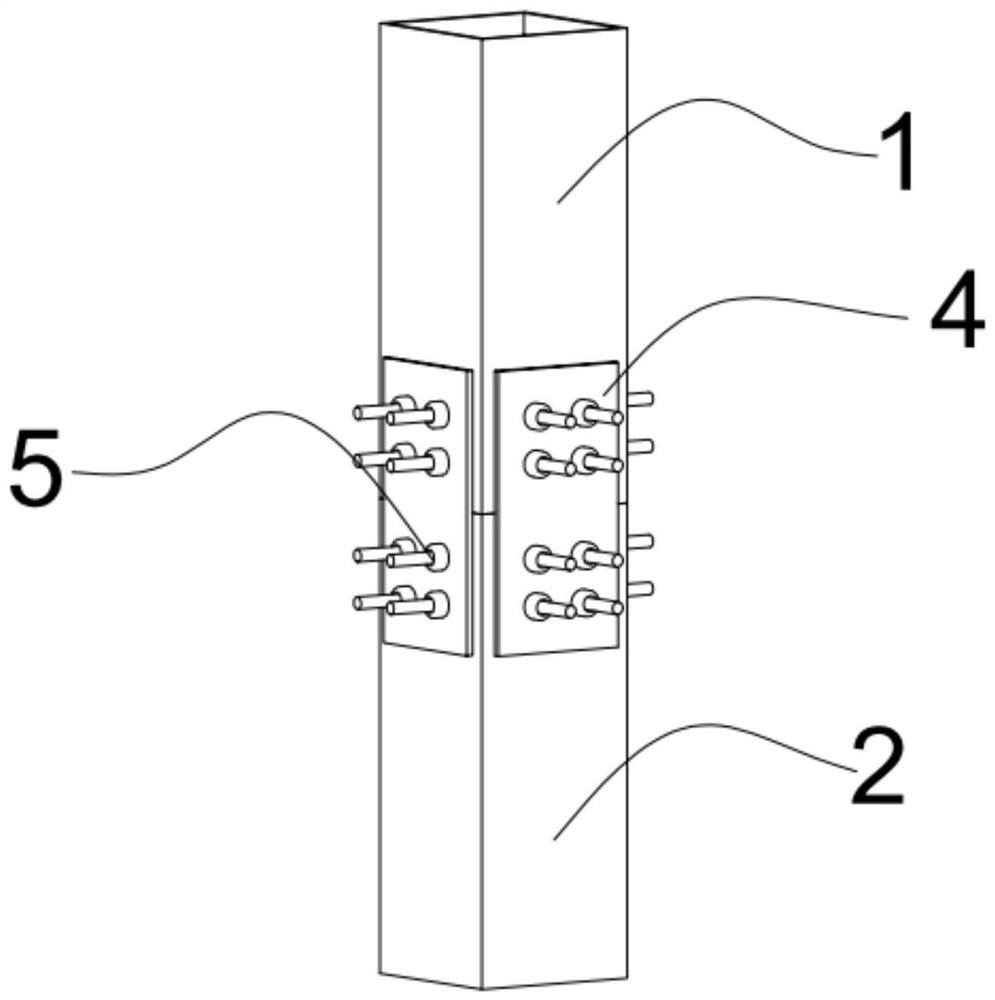

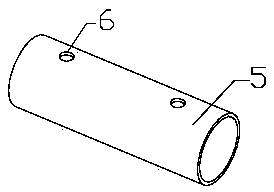

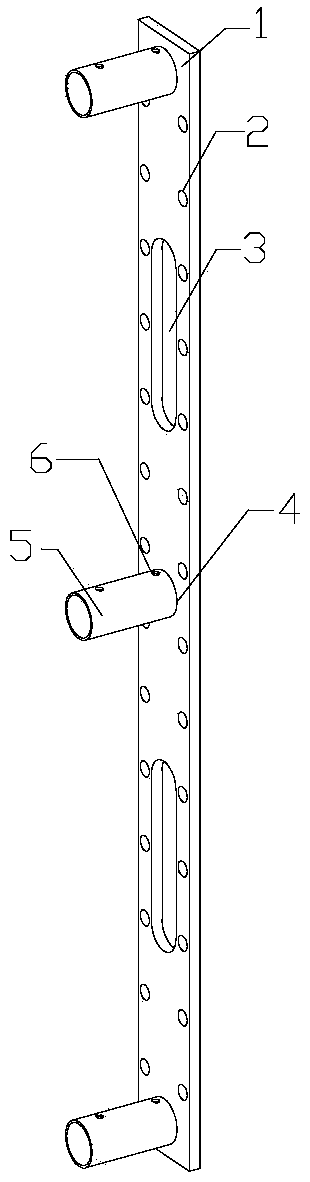

Pillar-to-pillar connecting joint

InactiveCN111809749AFirmly connectedThe power transmission path is clearStrutsPillarsSlag (welding)Classical mechanics

The invention provides a pillar-to-pillar connecting joint. The connecting joint comprises a first steel pillar, a second steel pillar, a connector, ring-grooved rivets and connecting plates; the first steel pillar, the second steel pillar and the connector are in a shape of a hollow pillar and are structurally identical; the first steel pillar and the second steel pillar are respectively sleevedat two ends of the connector; the outer side walls of the connector are attached to the inner side walls of the first steel pillar and the second steel pillar; the end parts of the first steel pillarand the second steel pillar are in contact with each other, and a plurality of the connecting plates are circumferentially arranged at the contact position; a plurality of bolt holes are formed in thefirst steel pillar, the second steel pillar, the connecting plates and the connector; and the steel pillars, the connecting plates and the connector are connected together via the ring-grooved rivets. According to the connecting joint, the bolt holes are formed in the end of sealed-section steel pillars, and the steel pillars, the connecting plates and the connector are connected together via thering-grooved rivets; the joint can realize reliable connection, and the force transmission path is explicit; and the defects of cracks, air holes, slag inclusion, incomplete fusion and incomplete welding which may occur in a welding process are effectively avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

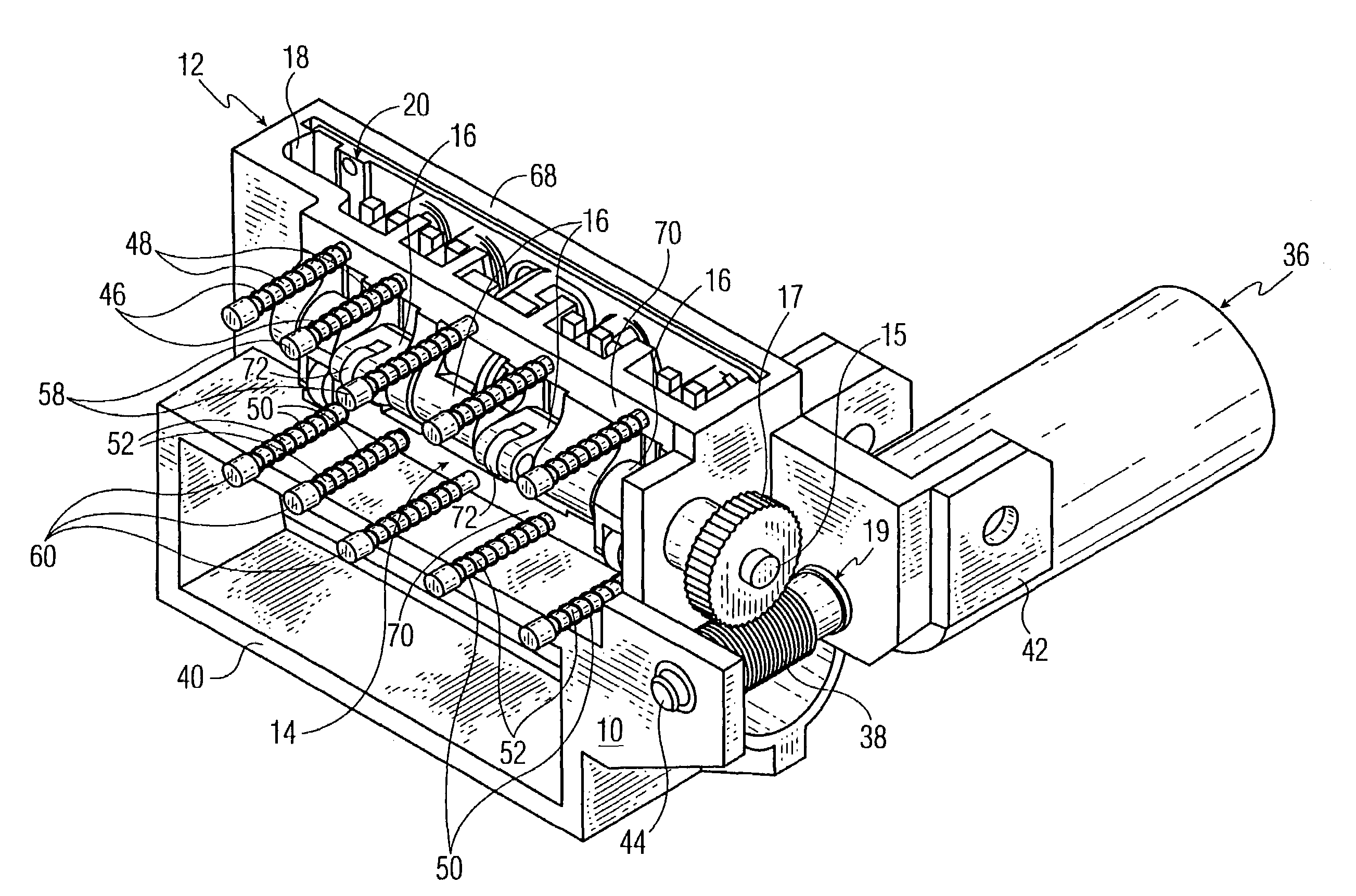

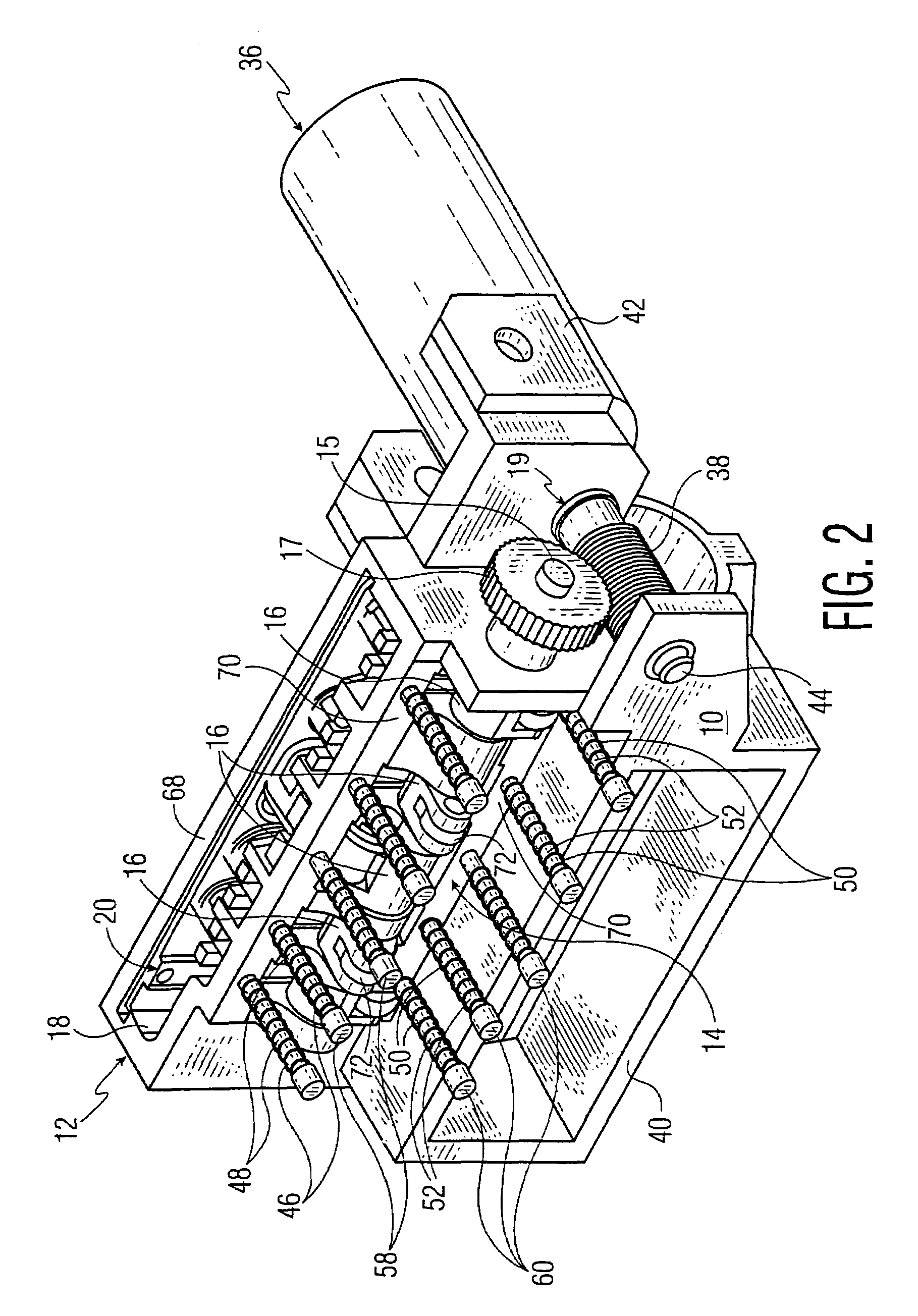

Program programming tooling system

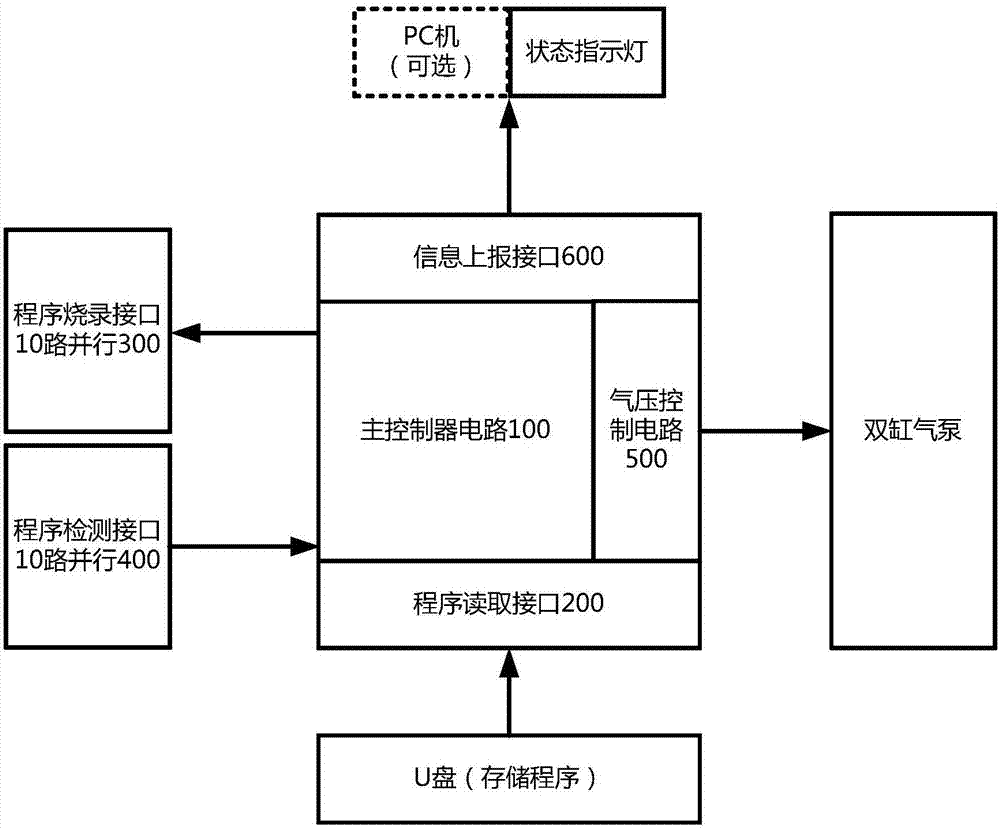

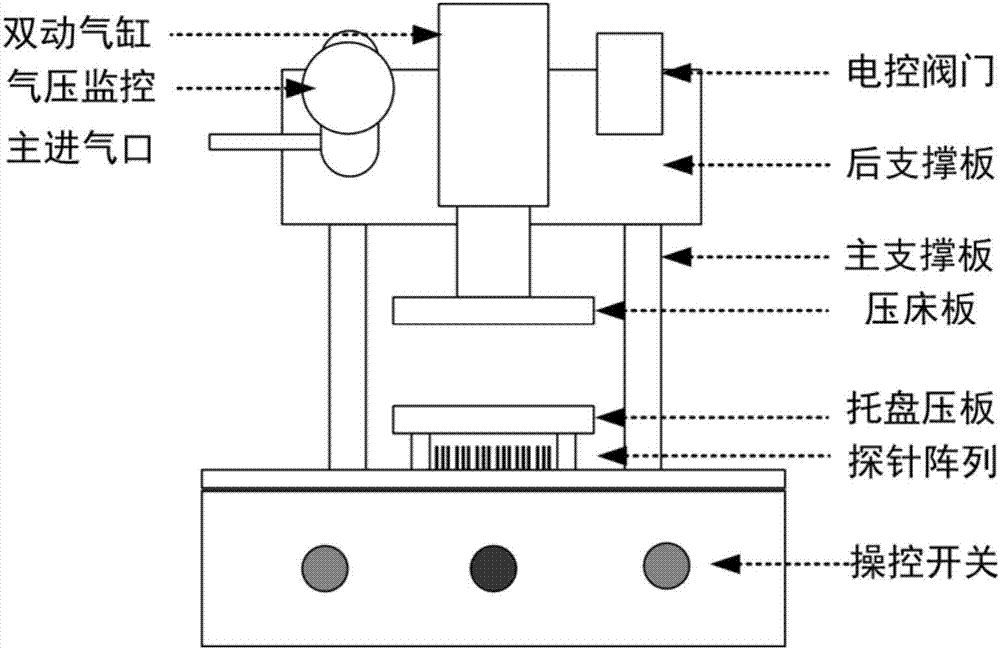

PendingCN107092500AReduce construction costsImprove efficiencyProgram loading/initiatingSoftware deploymentControl engineeringProcess engineering

The present invention proposes a program programming tooling system. The system comprises: a tooling platform, a main controller circuit, a program reading interface, a program programming interface, a program detection interface, an information reporting interface and an air pressure control circuit. The air pressure control circuit is located on the tooling platform, and the air pressure control circuit comprises a main air inlet, a double-action cylinder connected with the main air inlet through the pipeline, an electric control valve located at the front end of the double-action cylinder, and an air pressure monitoring device. The upper and lower movement of the pressing bar is triggered by the air pressure control circuit, and the movement of the press plate is further driven, so that the target chip is fixed on the tray platen, the relative ejector of the probe array is realized while pressing the tray platen downward, and the programming file output to the ejector is programmed to the target chip. According to the system provided by the present invention, the traditional manual pressing bar is replaced by the pneumatic pressing bar; and by introducing pneumatics, the manpower is saved, and the efficiency of automation equipment is higher.

Owner:科芯(天津)生态农业科技有限公司

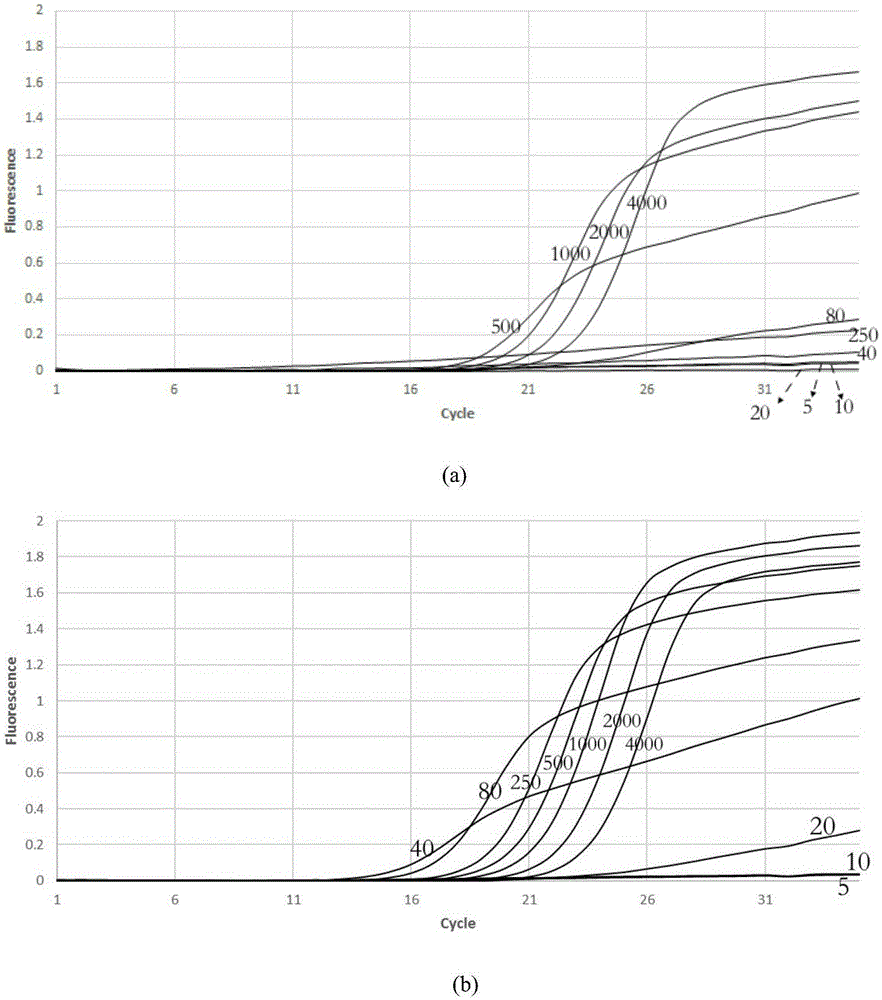

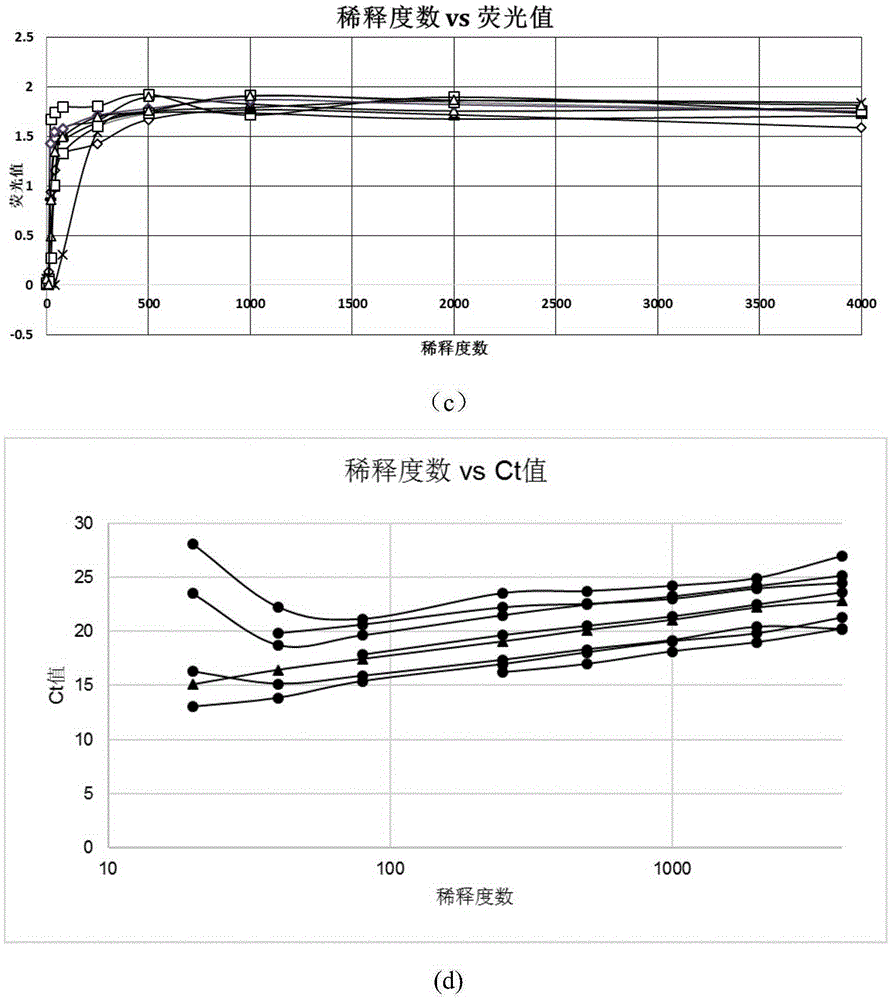

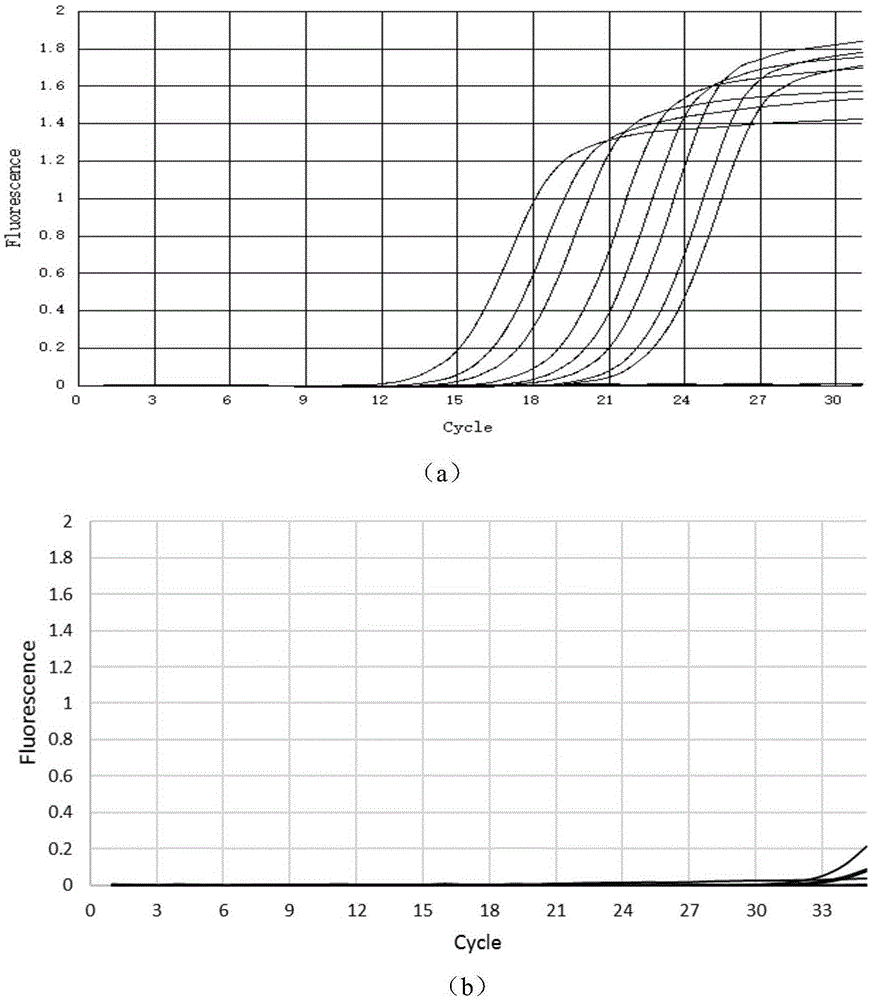

Colorectal cancer detection kit

PendingCN105349686AEasy to operateShort time spentMicrobiological testing/measurementFecesTrue positive rate

The invention belongs to the field of biomedicines, relates to a colorectal cancer detection kit, and more particularly relates to a colorectal cancer detection kit taking excrement as a detection sample. The detection kit is characterized in that an Alu detection reagent and PvPP are contained. Through multi-time exploration in numerous colorectal cancer markers, Alu is discovered that the sample can be directly diluted for PCR amplification detection without going through complex steps of cell disruption, DNA extraction and the like on the premise of proper simple pretreatment, and good sensitivity and specificity are obtained.

Owner:CREATIVE BIOSCIENCES (GUANGZHOU) CO LTD

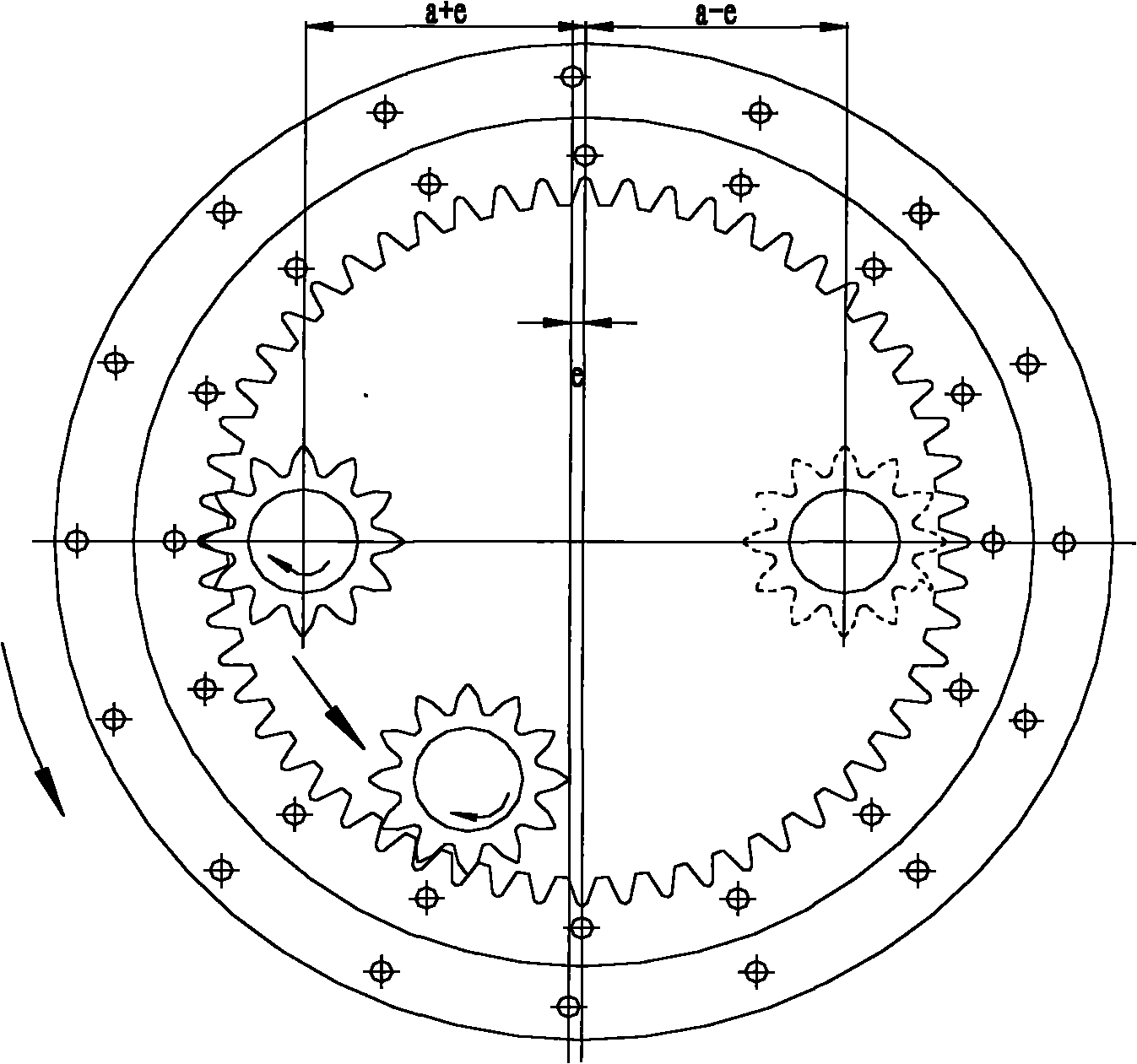

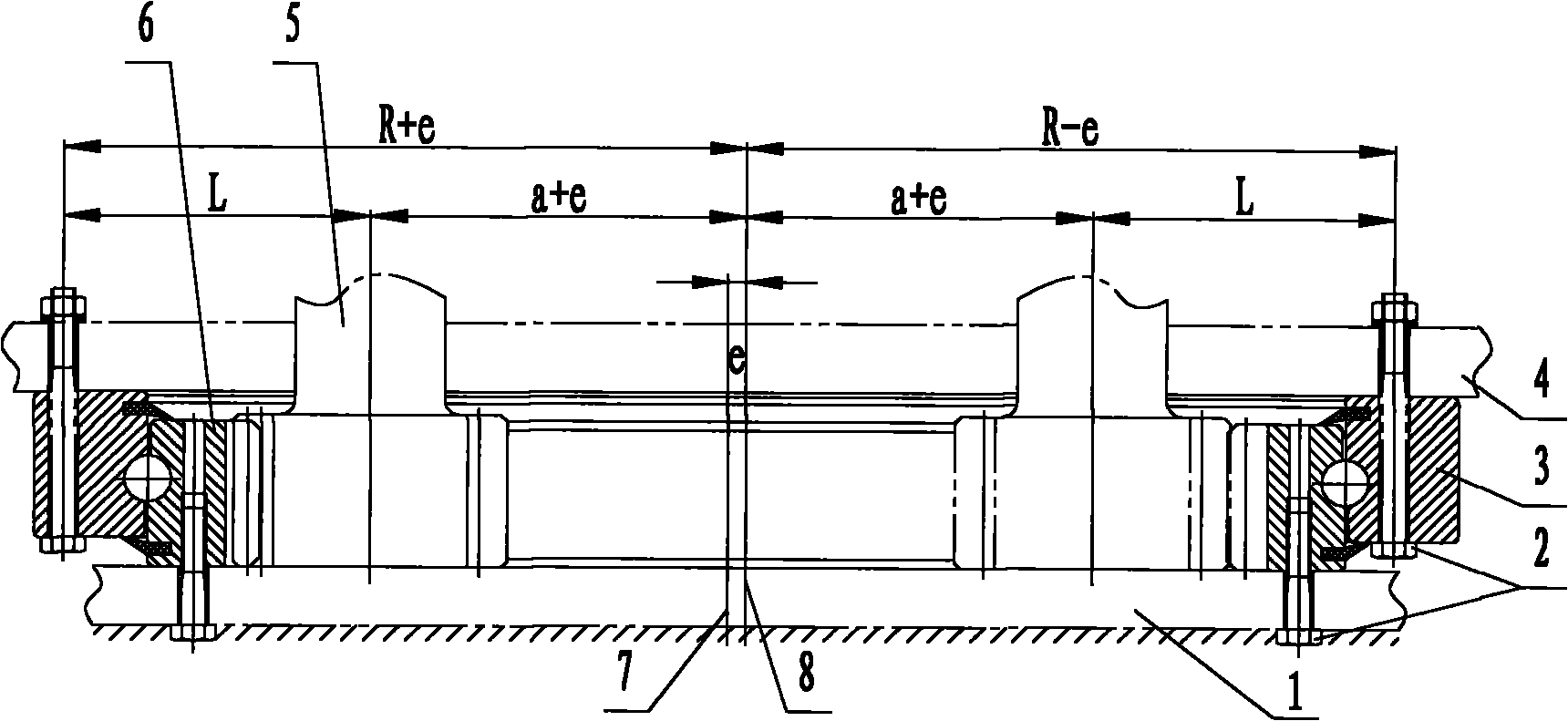

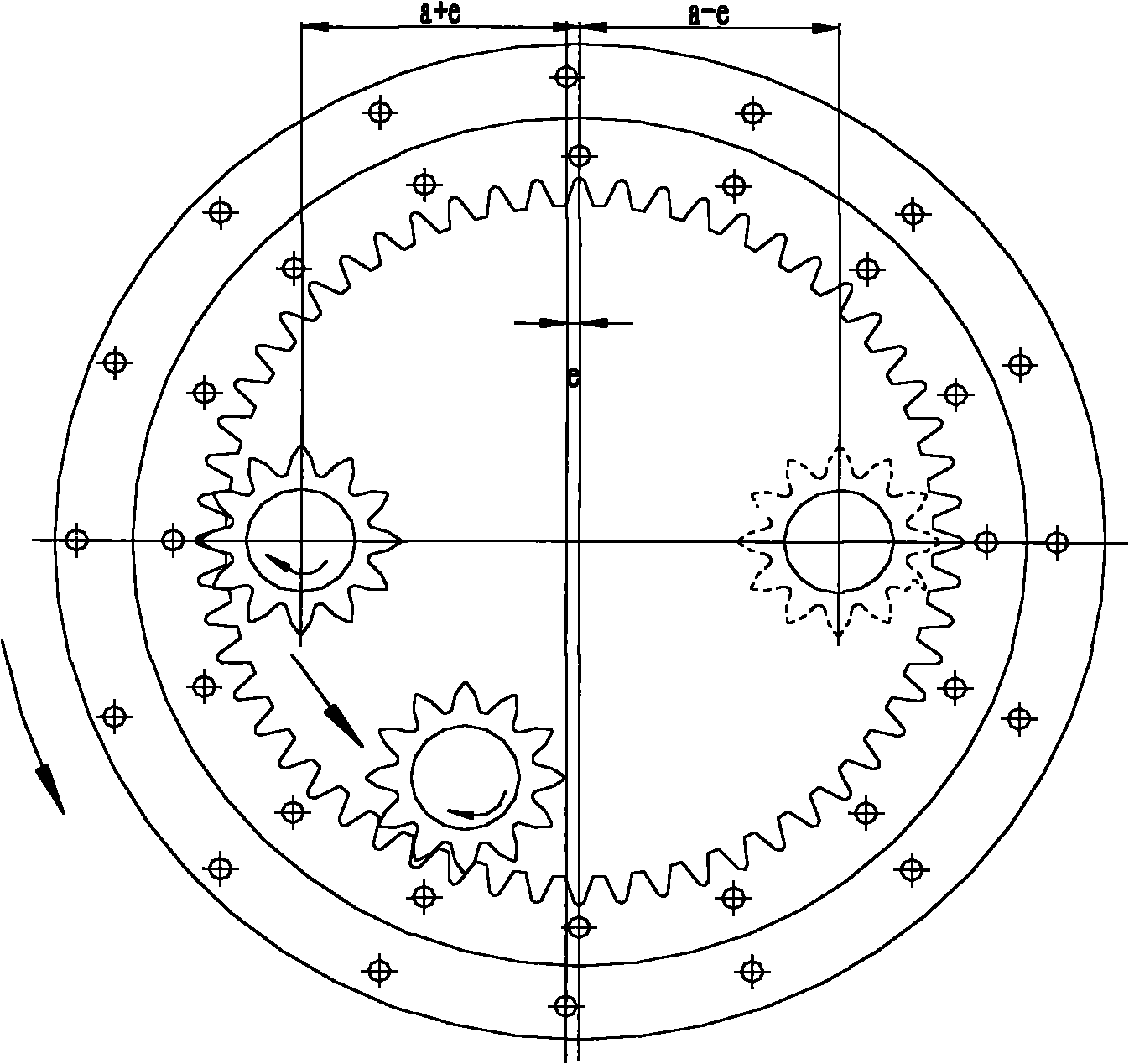

Slewing bearing with adjustable gear meshing center distance and machining method thereof

InactiveCN101813178AReduce scrap rateReduce investmentPortable liftingGearing elementsWork performanceGear wheel

The invention discloses a slewing bearing with an adjustable gear meshing center distance and a machining method thereof. The slewing bearing comprises a support ring without a gear ring and a support ring with a gear ring, wherein the two support rings are matched with each other; and the center of a mounting hole of the support ring without the gear ring and the center of the slewing bearing have an eccentric distance (e). The slewing bearing can adjust the center distance between small gears on a main machine and the support ring with the gear ring of the slewing bearing and solves the problem of reutilization of a frame of the main machine with an ultra-poor position degree of the mounting hole, thereby finally achieving the purposes of reducing the machining difficulty of the main machine and improving the working performance and the service life of the slewing bearing.

Owner:马鞍山统力回转支承有限公司

Preparing method for cream smell pig feed attractant

InactiveCN105595027AStrong aromaNot easy to change colorAccessory food factorsEthyl acetateMethyl oleate

The invention relates to a preparing method for a cream smell pig feed attractant. The preparing method comprises the steps that firstly, cis-6-nonadienal, ethyl acetate, methyl thiobutyrate, ethyl vanillin, ethyl lactate, octylic acid, milk lactone, butyric acid, furanone, sulfur alcohol, ethyl oleate, delta-decalactone, decylic acid, butter ester, delta-dodecalactone and butter acid are added into a stirring barrel according to the content, heated to 45 DEG C, and stirred evenly; secondly, the evenly-stirred mixture is cooled and then added into a carrier to be evenly mixed, and the finished product is obtained. According to the preparing method for the cream smell pig feed attractant, a newest product formula is adopted, the attractant is thick in aroma, not likely to change colors, resistant to high temperatures, long in aroma remaining time, stable in quality and capable of being used in feed for pigs in different stages, raw materials are convenient to obtain, the preparing process technology is simple and easy to implement, the requirement for equipment and personnel is low, and mass popularization is facilitated.

Owner:上海美农生物科技股份有限公司

On-line monitoring device and method for preparing tobacco essence perfume

ActiveCN102566533BHigh precisionFast analysisTotal factory controlProgramme total factory controlControl systemMahalanobis distance

The invention discloses an on-line monitoring device for preparing tobacco essence perfume. According to the on-line monitoring device, one or more process monitoring points are provided with sampling pipelines respectively; near infrared optical fiber probes are arranged behind the sampling pipelines respectively; a plurality of near infrared optical fiber probes at different process monitoring points share and are connected with a near infrared spectrometer; and the near infrared spectrometer is connected with a perfume kitchen master control system through a data line. The near infrared spectrum technology is applied to on-line real-time monitoring of the tobacco essence perfume preparation process. After establishing the on-line monitoring device and a model, a quantitative chemical index and a mahalanobis distance of a sample can be obtained in real time by scanning a spectrum of the sample on line and are compared with control requirements; and if abnormity occurs, the master control system alarms to prompt the technical personnel to search the reason.

Owner:CHINA TOBACCO FUJIAN IND

Method for simultaneously preparing CBG, CBDV, CBD and THCV from industrial hemp

PendingCN112062658ALow costReduce usageOrganic chemistryOrganic compound preparationDistillationPhysical chemistry

The invention discloses a method for simultaneously preparing CBG, CBDV, CBD and THCV from industrial hemp. The method comprises the following steps of: (1) raw material crushing; (2) drying; (3) extraction: extracting, concentrating and freezing baked floral leaf powder and ethanol according to a solid-to-liquid ratio of 1: (8-12); (4) filtering: filtering the frozen concentrated solution, and extracting to obtain a hemp extract; (5) molecular distillation: carrying out molecular distillation on the hemp extract for three times; (6) chromatographic column separation: dissolving CBG, CBDV, CBDand THCV oil obtained by distillation with ethanol with the mass concentration of 60%, and then loading a sample by a wet method for chromatographic column separation; and (8) recrystallization: respectively dissolving the prepared CBG crystal, CBDV crystal, CBD crystal and THCV oil with ethanol, recrystallizing, washing and drying to obtain the finished products CBG crystal, CBDV crystal, CBD crystal and THCV crystal. The raw materials and reagents used in the method are cheap, easy to obtain and low in cost, the adopted operation and method are simple and easy to implement, and the preparedproduct is high in purity and good in safety.

Owner:滇麻生物科技(曲靖)有限公司

Method for dewaxing and decoloring cannabidiol extract

PendingCN111943815AGuaranteed Extraction PurityGuaranteed withdrawal rateOrganic chemistryOrganic compound preparationWaxSolvent

The invention discloses a method for dewaxing and decoloring cannabidiol extract, which is characterized by comprising the following steps: (1) pretreatment of raw materials: crushing industrial hempflower leaves, conducting baking for decarboxylation, and conducting extracting with an extracting agent at normal temperature to obtain crude extract; (2) dewaxing: dissolving the extract crude extract with ethanol to obtain an extract mixed solution, then adding a filter aid into the extract mixed solution, and carrying out freezing, cold filtration, washing, evaporation and concentration to obtain a wax-free extract crude product; and (3) decolorization: dissolving the wax-free extract crude product with ethanol to obtain a dissolved solution, adding a decolorizing agent into the dissolvedsolution, and conducting decolorizing, filtering, washing, filtering again, evaporating and concentrating to obtain golden yellow or yellowish-brown wax-free CBD extract. The method has the advantagesof simplicity in operation, lower requirement on personnel, small solvent consumption, low equipment requirement, remarkable dewaxing and decoloring effects, reasonable process, environmental protection and high efficiency.

Owner:滇麻生物科技(曲靖)有限公司

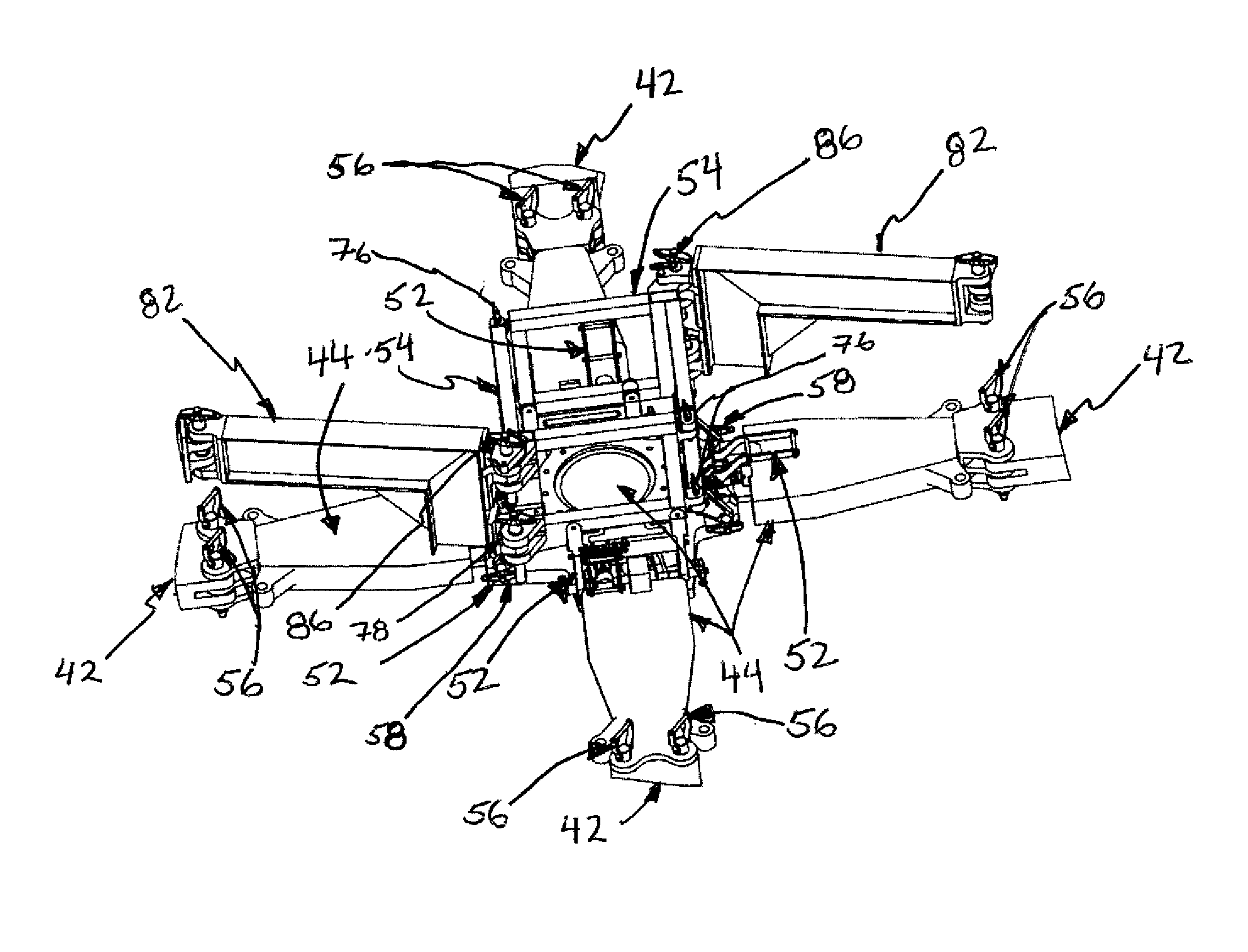

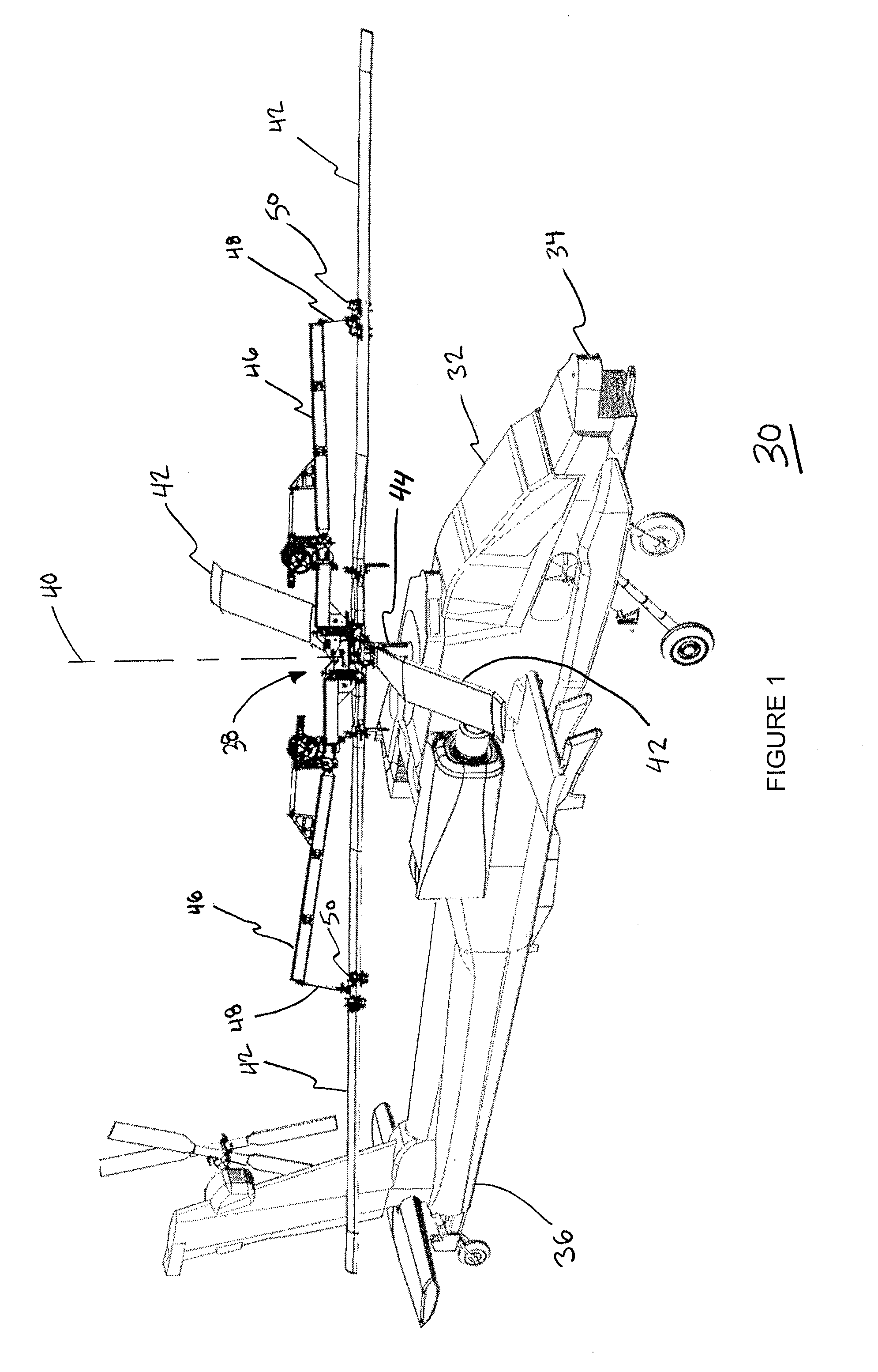

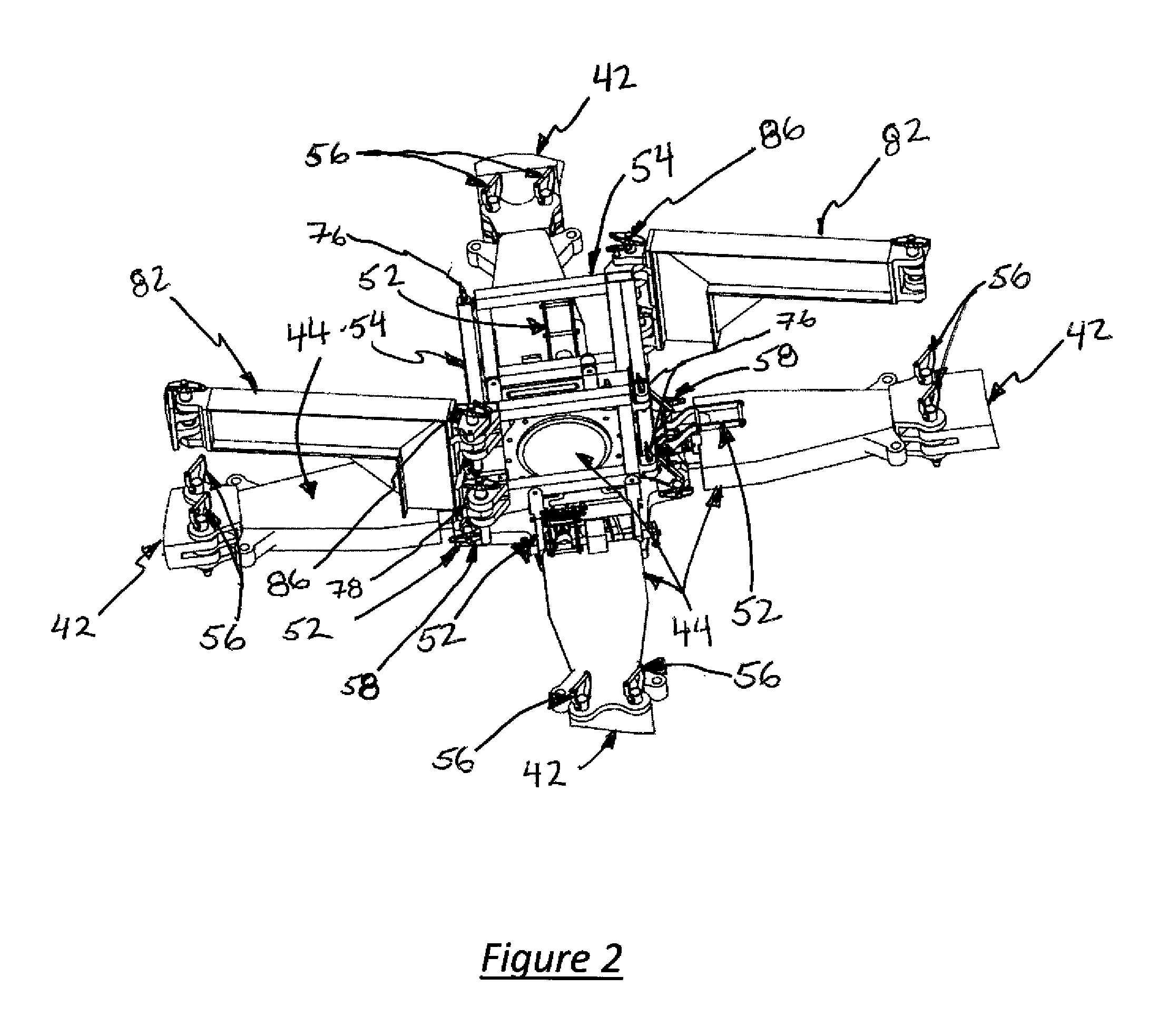

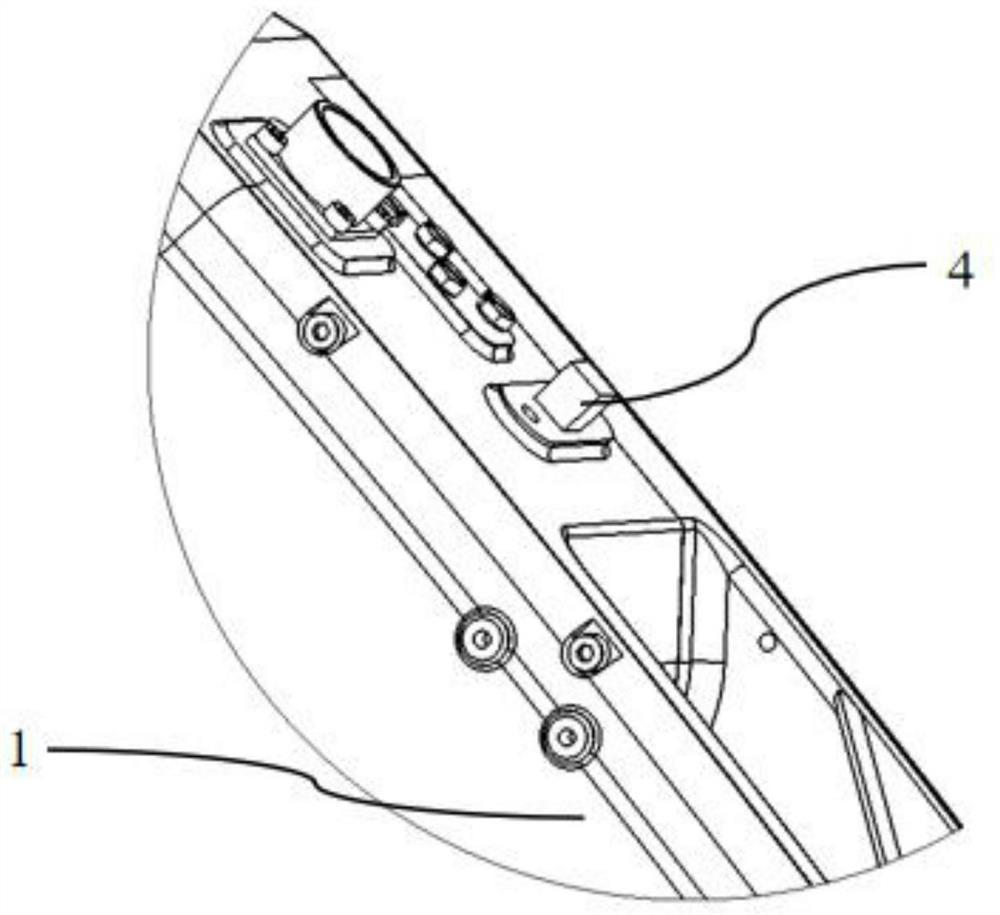

Helicopter blade folding apparatus

ActiveUS20160368598A1Less-difficult and more controlled foldingReduce stressRotocraftEngineeringMechanical engineering

The present invention relates to a blade folding apparatus that may incorporate an overhead blade lifting system that reduces binding loads on blade pins induced by blade weight and pitch, and a folding mechanism that removes the necessity of personnel with external guide-poles to rotate main rotor blades. The apparatus may include flap locks, an overhead lifting system support structure attached to the flap locks, and two blade support beams to create and support a lifting point near each blade's longitudinal and lateral center of gravity. The blade support beams may be fitted with an articulation mechanism that lifts and / or lowers the overhead lifting structure. The apparatus facilitates rapid folding of the main rotor blades, and, when used with blade clamping mechanisms, is capable of aiding in the removal and / or the re-installation of the main rotor blades without external lifting mechanisms.

Owner:HII MISSION TECH CORP

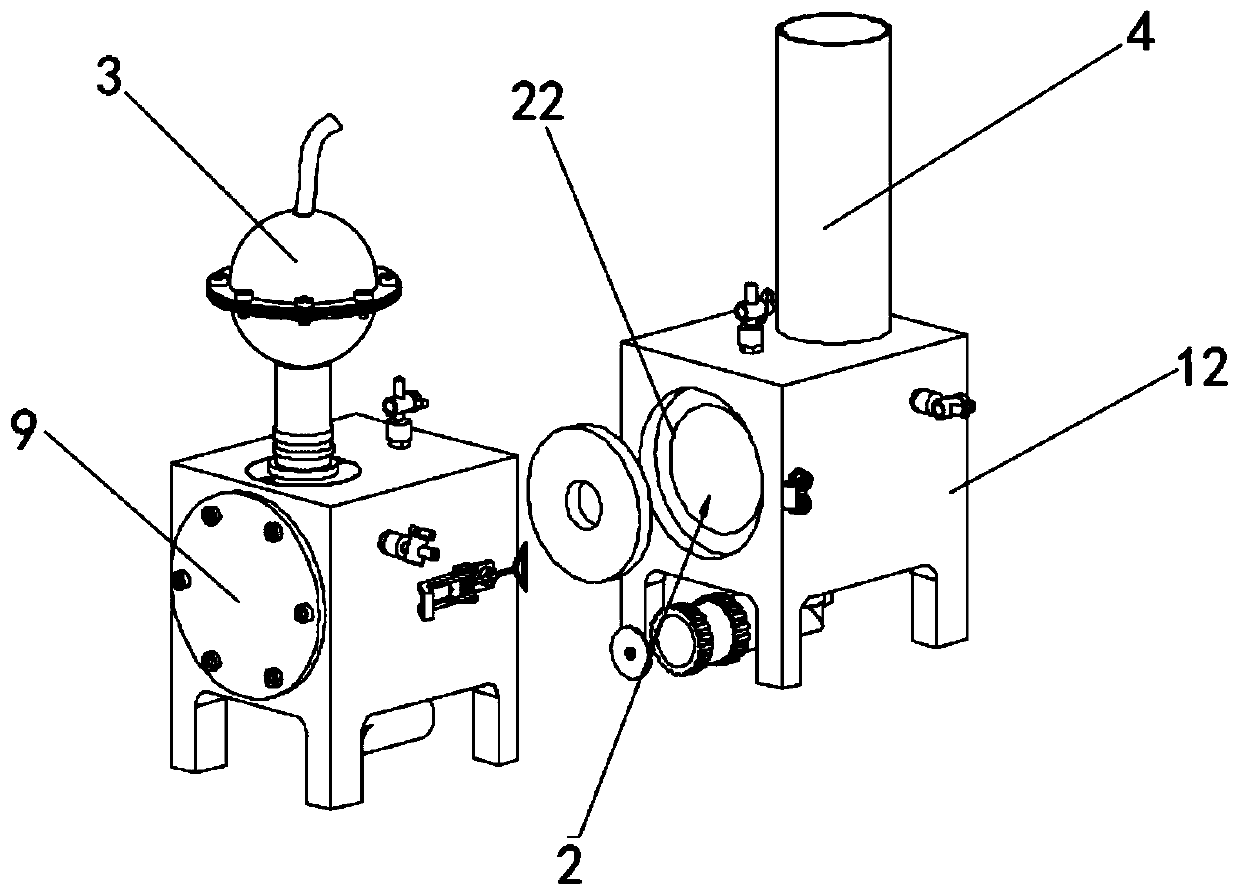

Cardiac valve opening and closing detector

The invention relates to the technical field of medical apparatus and instruments, in particular to a cardiac valve opening and closing detector. The detector comprises an outer shell body, a testingcavity, a testing cavity, a pressure boost device, a compliance cavity, a backflow pipe, a valve fixture, a quick dismounting element and an air outlet, wherein the front end and the rear end of the testing cavity are independently provided with an opening; an observation window is independently arranged on the openings on the front end and the rear end of the testing cavity on the outer shell body; and the pressure boost device and the testing cavity, the compliance cavity and the testing cavity, the backflow cavity and the testing cavity as well as a Luer taper and the testing cavity can bein through arrangement. The detector can use a syringe as a power source and also can use various pneumatic and liquid-operated pulsating pumps as power sources. Meanwhile, due to a special power transmission system, the liquid or the gas of a power mechanism can be isolated from an aseptic liquid in a cavity body so as to prevent the liquid and the gas in the pump from being in contact with the liquid in the cavity, bacteria are effectively isolated, and the waste of the liquid is reduced.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

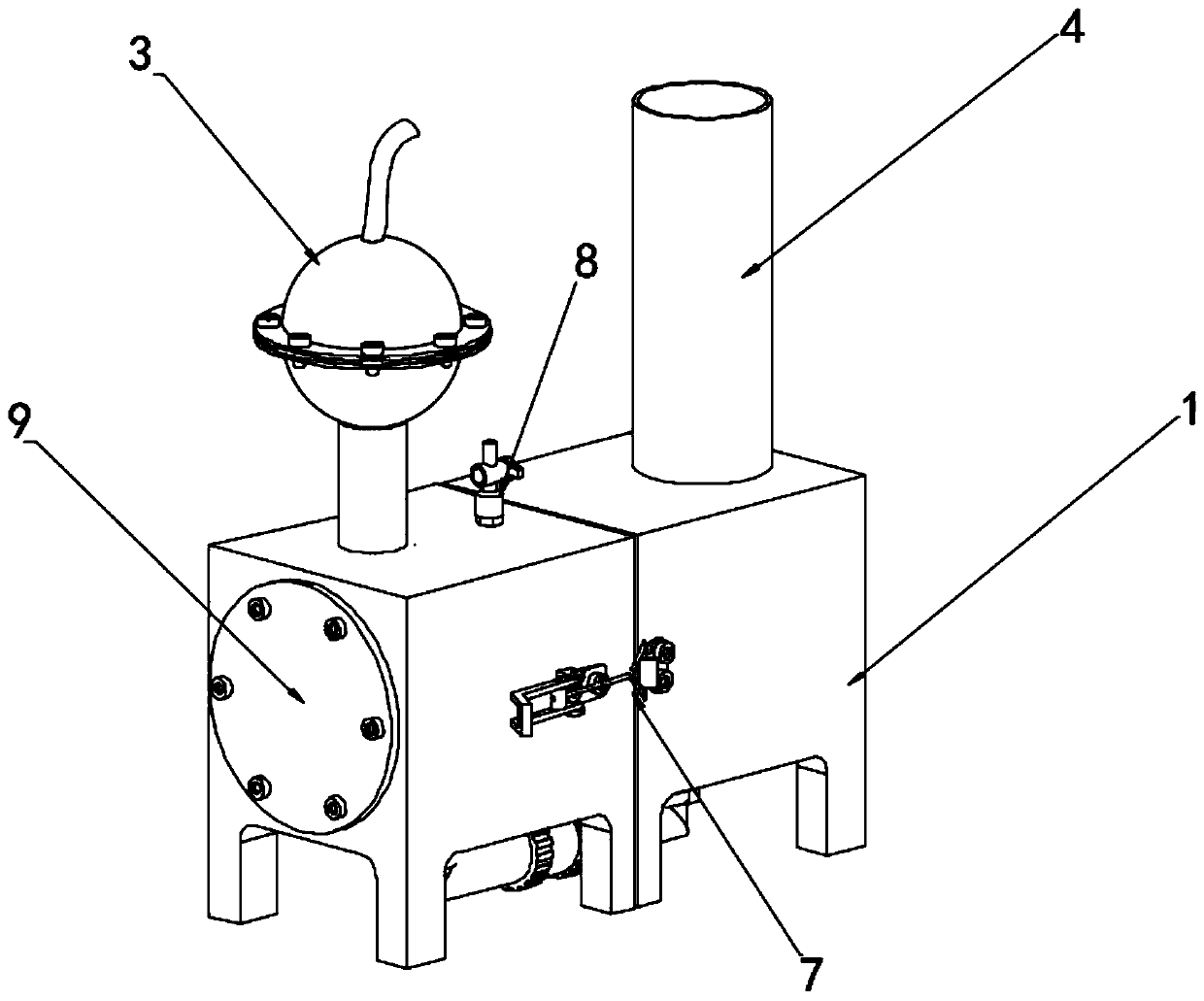

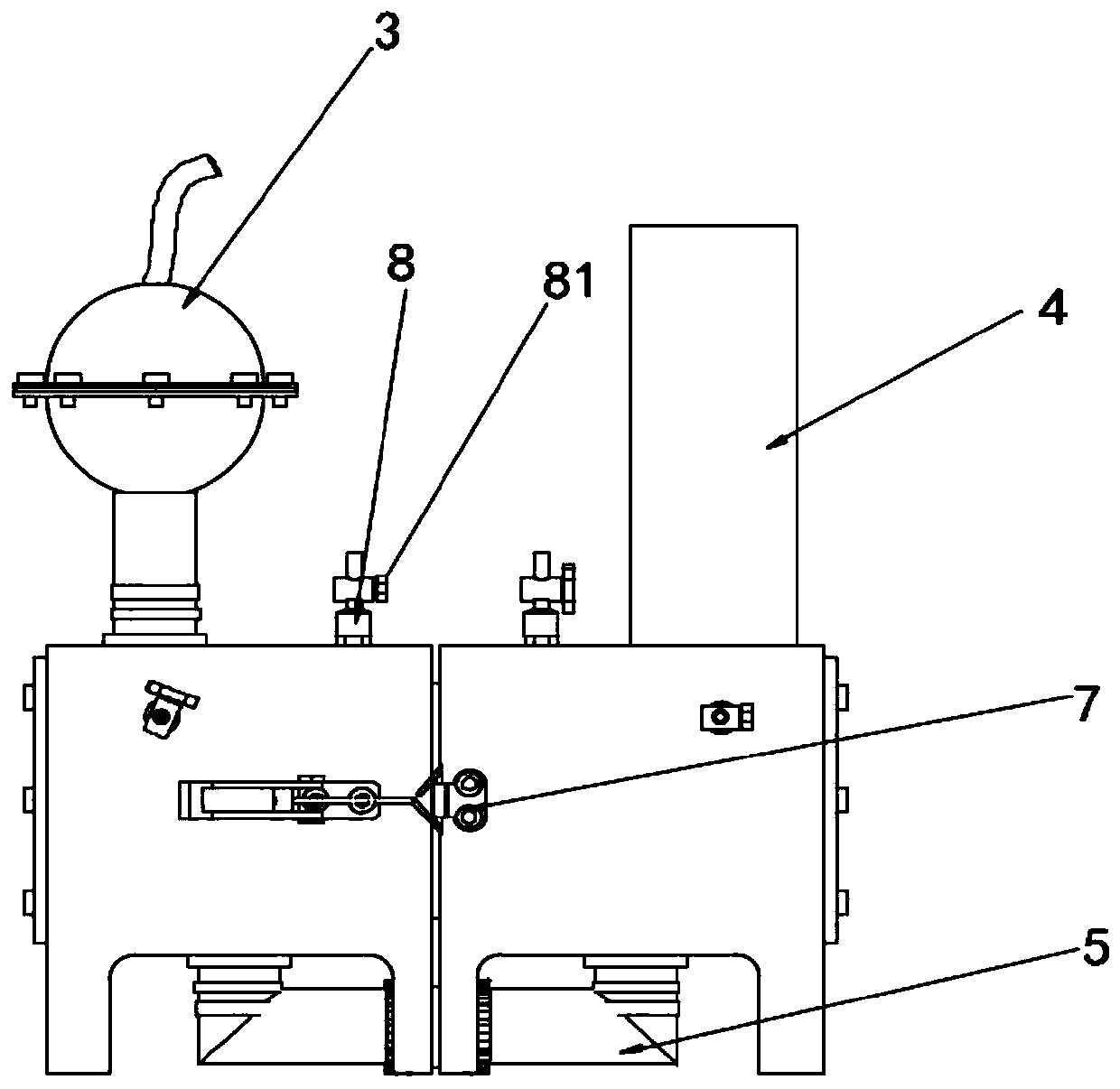

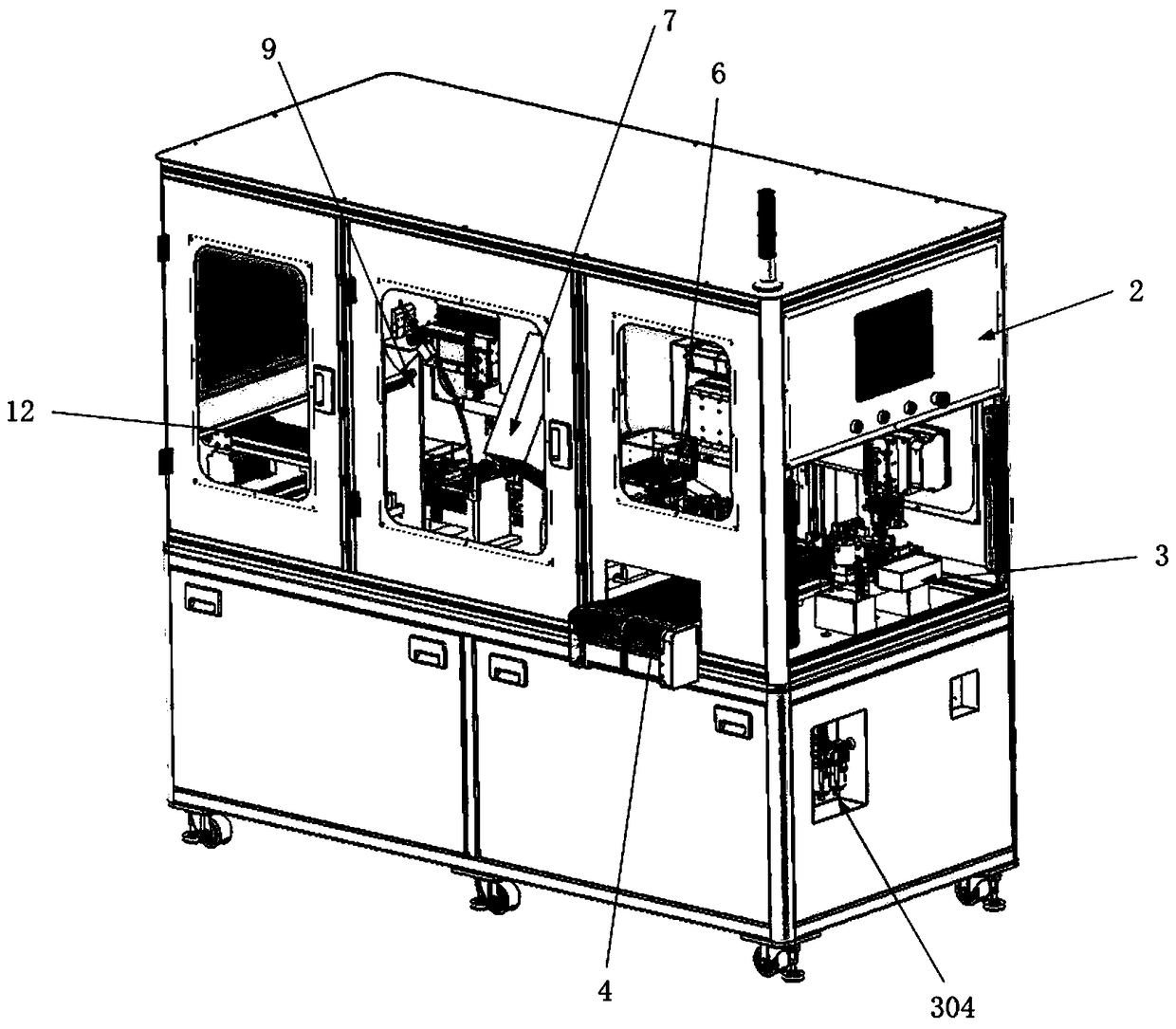

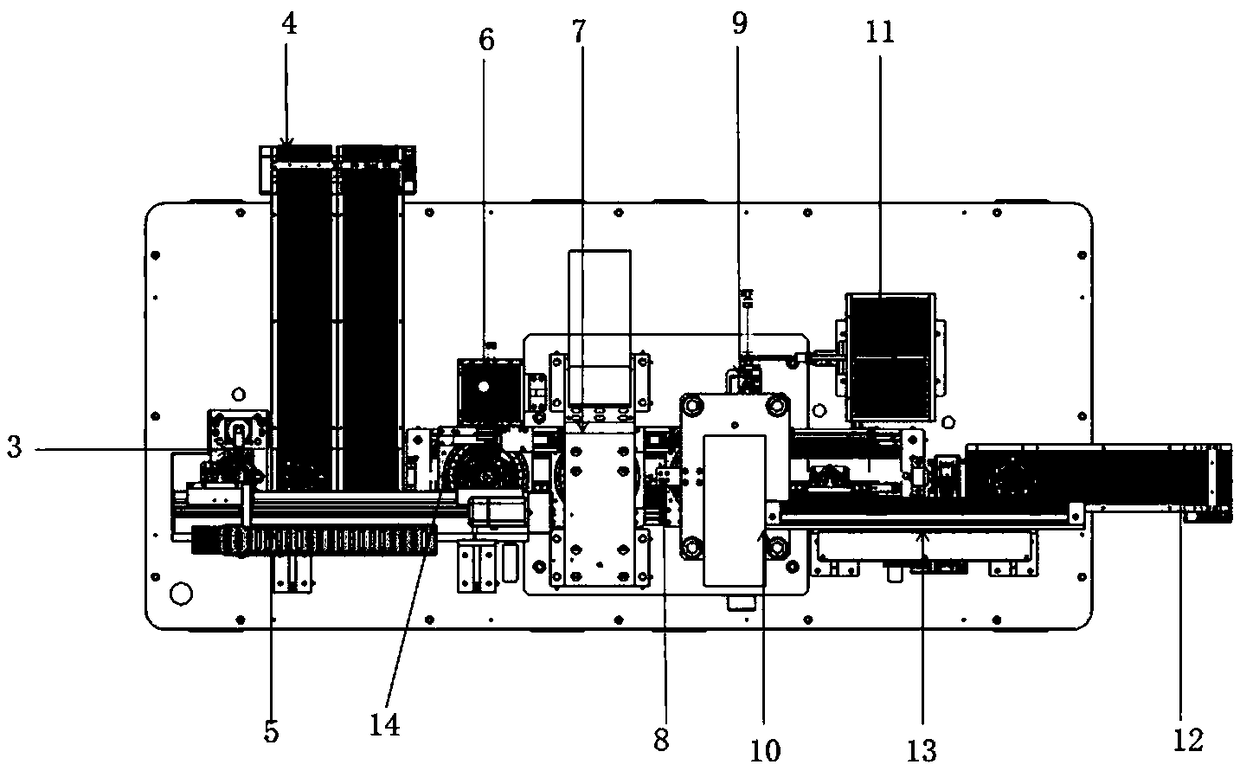

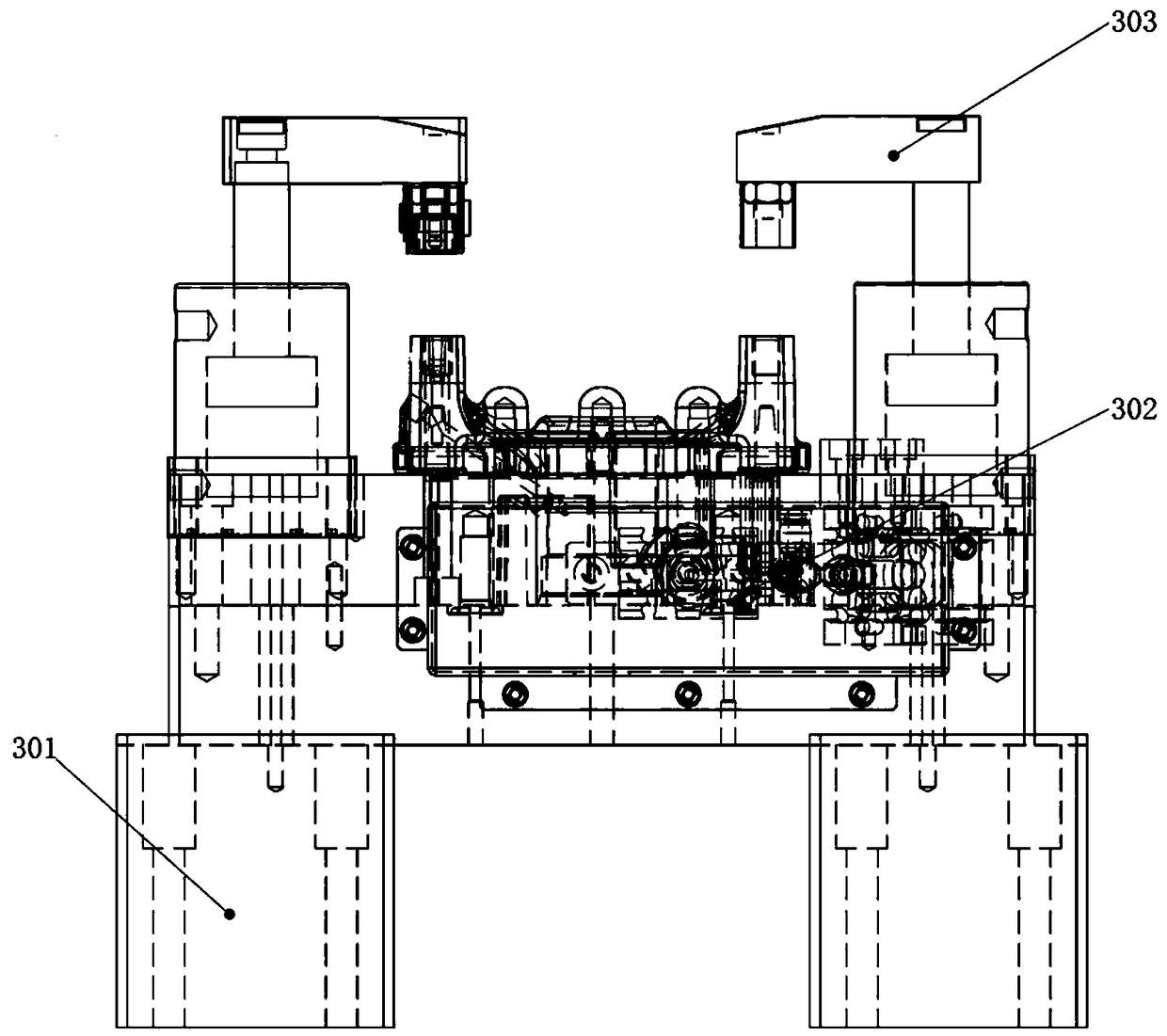

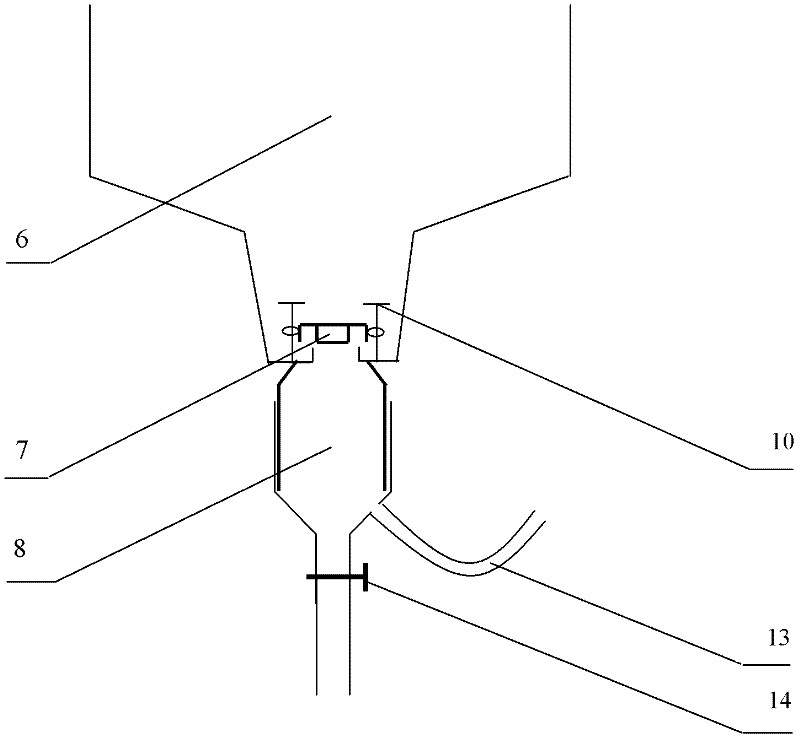

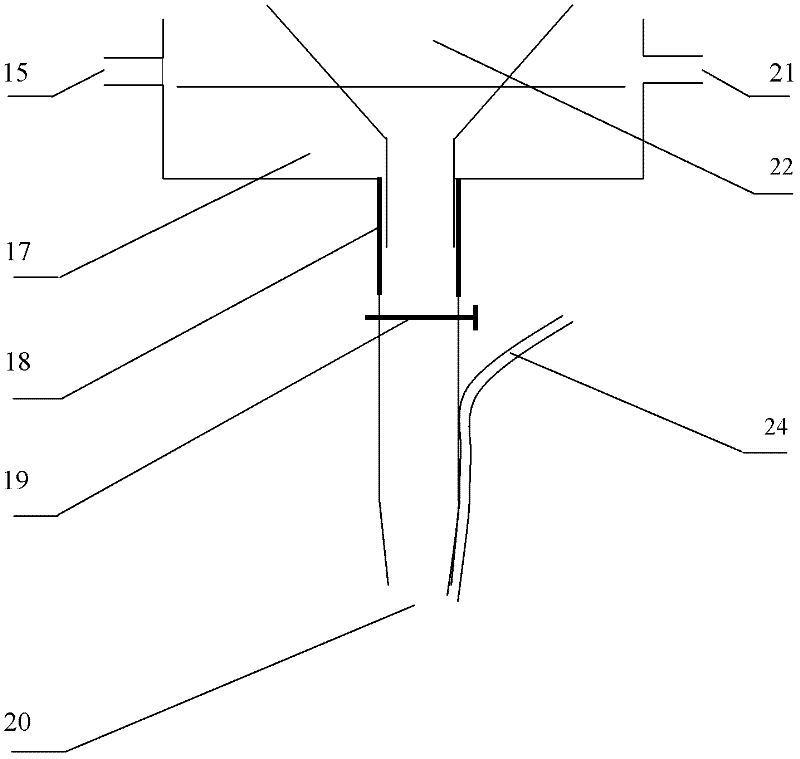

Automatic assembly test machine

InactiveCN109262253ASmooth and efficientLow personnel and site requirementsMeasurement of fluid loss/gain rateAssembly machinesTransfer mechanismManipulator

The invention provides an automatic assembly test machine. The machine comprises a cabinet (1), a control panel (2) disposed on one side of the cabinet (1), a airtightness detecting device (3), a first conveyor belt (4), a first manipulator (5), a steel ball loading mechanism (6), a pressure steel ball mechanism (7), a marking mechanism (8), a pin sleeve feeding mechanism (9), a press pin mechanism (10), a pin bushing feeding mechanism (11), a second conveyor belt (12), a second manipulator (13) and a transfer mechanism (14), and solves the technical problems in the prior art that automatic completing is not achieved, the whole process is not smooth, the efficiency is low, the requirements for personnel and sites are high, and the cost is high, and the technical effects that the entire assembly test process is completed automatically, the whole process is smooth and highly efficient, the requirements for the personnel and the sites are low, and the cost is low are achieved.

Owner:深圳市伟创诚科技有限公司

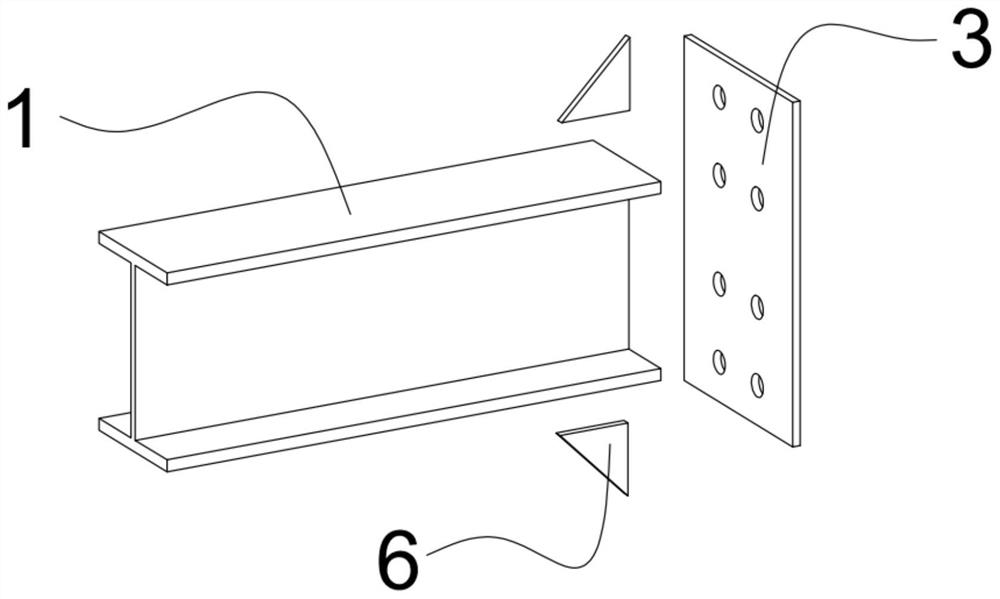

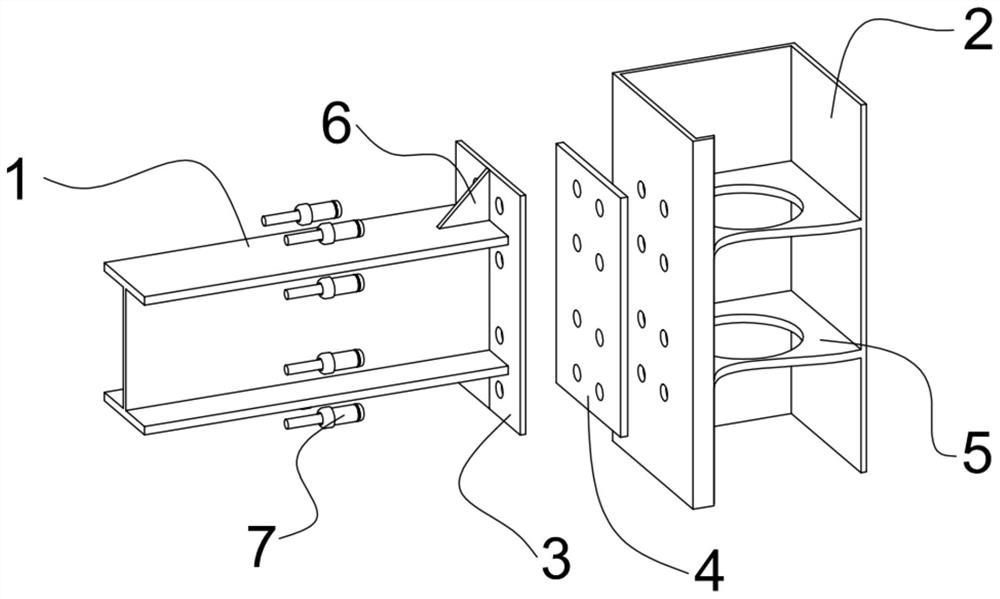

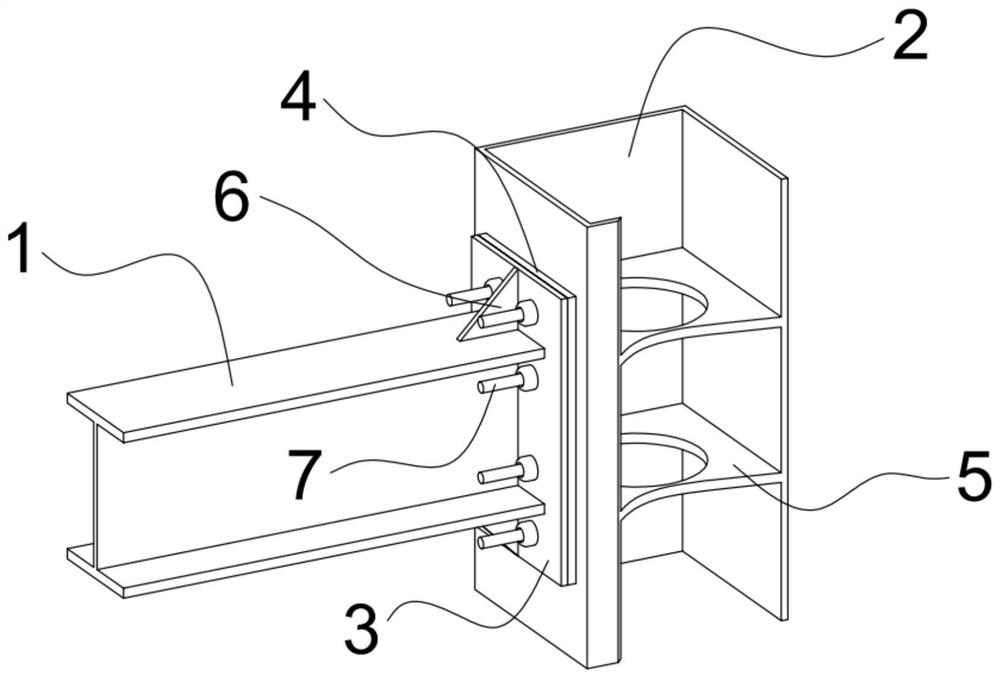

Beam column splicing joint

InactiveCN111809747AFirmly connectedThe power transmission path is clearBuilding constructionsSlag (welding)Classical mechanics

The invention discloses a beam column splicing joint. The beam column splicing joint comprises a steel beam, a steel column, a steel beam end plate, a connecting plate and ring groove rivets; the steel beam end plate is fixedly arranged at the end part of the steel beam, the steel beam end plate is arranged on one side surface of the steel column, and the connecting plate is arranged between the steel beam end plate and the steel column; and bolt holes are correspondingly formed in the side surfaces of the steel beam end plate, the connecting plate and the steel column, and the side surfaces of the steel beam end plate, the connecting plate and the steel column are fixedly connected through the ring groove rivets arranged in the bolt holes. According to the beam column splicing joint, thebolt holes are formed in the side surface of the steel column with a closed section, the steel column, the connecting plate and the steel beam are connected together through the ring groove rivets, the joint connection in this way is reliable, the force transmission path is clear, and the defects such as crack, air holes, slag inclusion, incomplete fusion and incomplete penetration in the weldingprocess are effectively avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

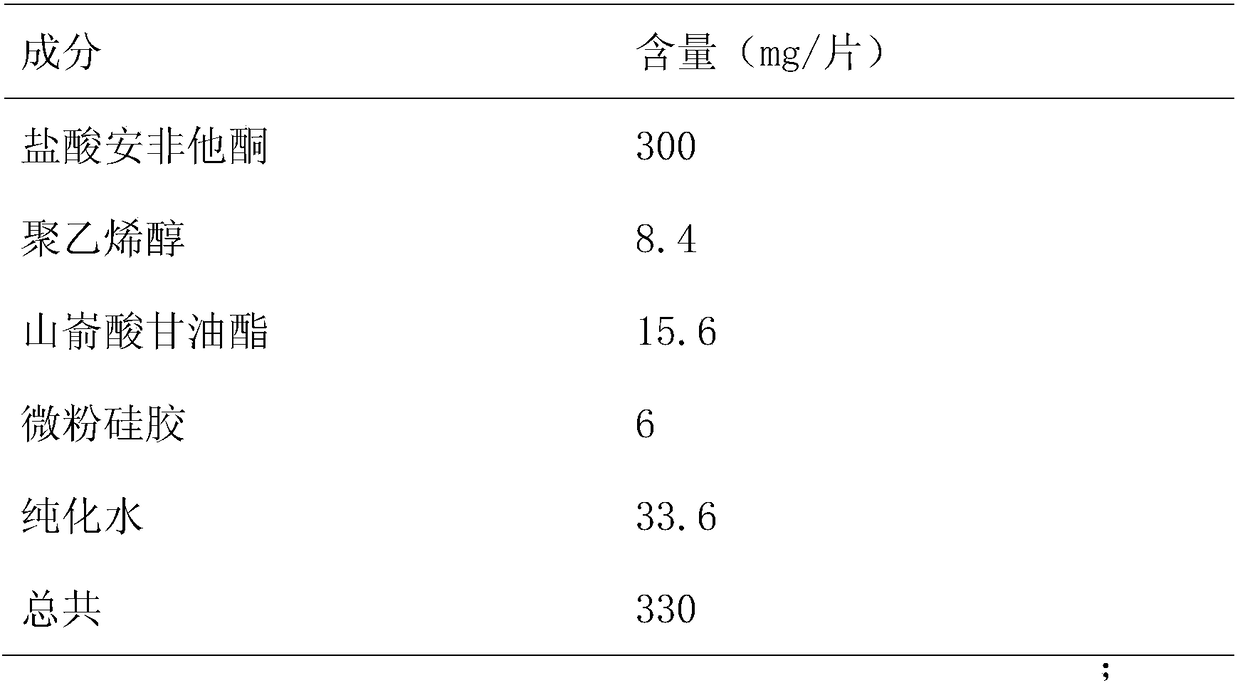

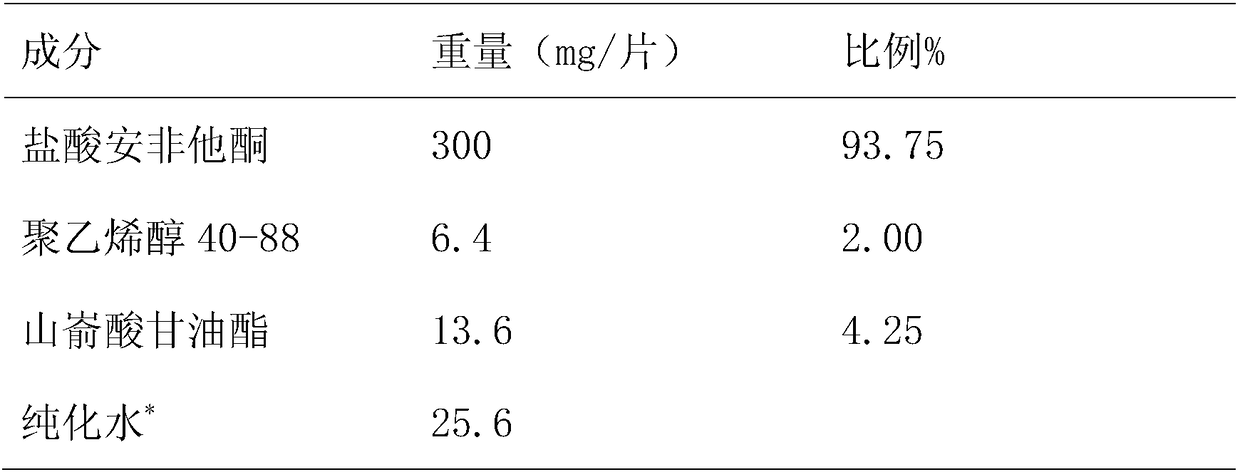

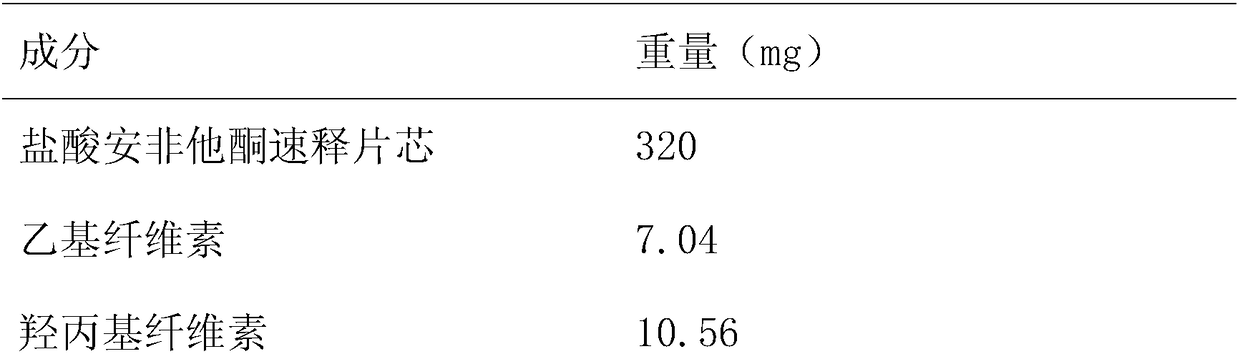

Preparation method for quick-release tablet cores of bupropion hydrochloride enteric-coated and sustained-release tablets

InactiveCN108261402AReduce the incidence of epilepsyReduce lossOrganic active ingredientsNervous disorderBupropion hydrochlorideMedicine

The invention provides a preparation method for quick-release tablet cores of bupropion hydrochloride enteric-coated and sustained-release tablets. The preparation method comprises the following steps: dissolving polyvinyl alcohol in water to prepare 20% of a concentration adhesive; placing bupropion hydrochloride in a high-shear wet-process granulator; adding 20% of adhesive polyvinyl alcohol; stirring and cutting uniformly to obtain particles; sieving the wet particles by using a 1 mm sieve; after drying, granulating, adding superfine silica powder and mixing for 20 min; and adding glycerylbehenate and mixing uniformly, and carrying out tabletting to obtain the quick-release tablet cores of the bupropion hydrochloride enteric-coated and sustained-release tablets. High-shear wet-processgranulating is carried out, the process is simple and easy to operate, the production time is greatly shortened, loss of crude drugs is reduced, the yield is improved, and preparation stability is improved. The method is suitable for industrial production, and has high application value.

Owner:SHANGHAI SUNTECH PHARMA

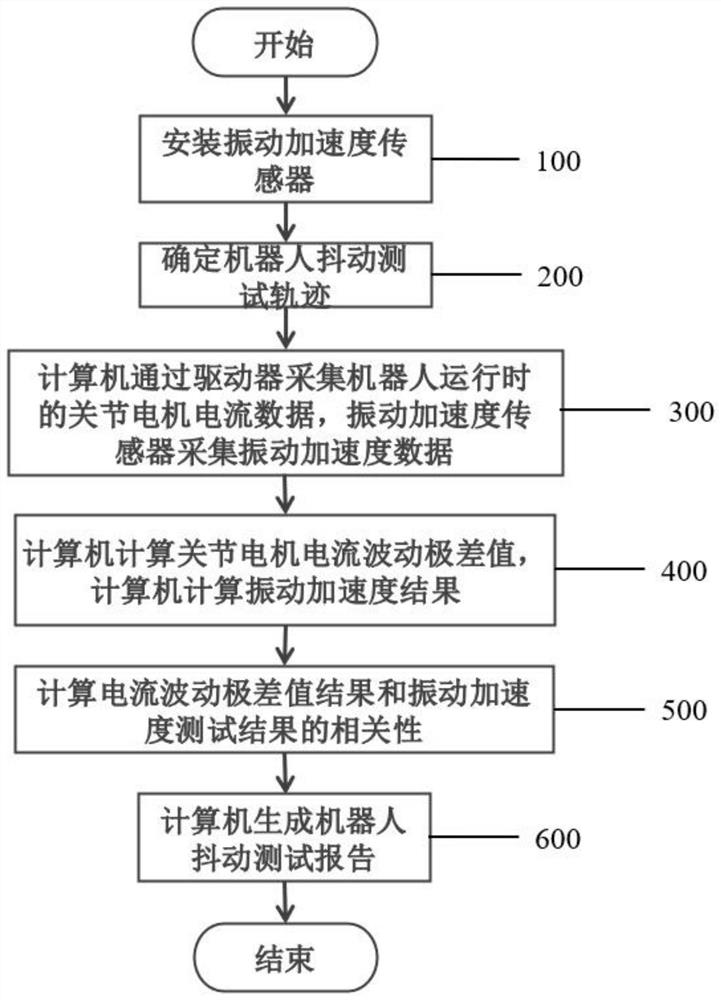

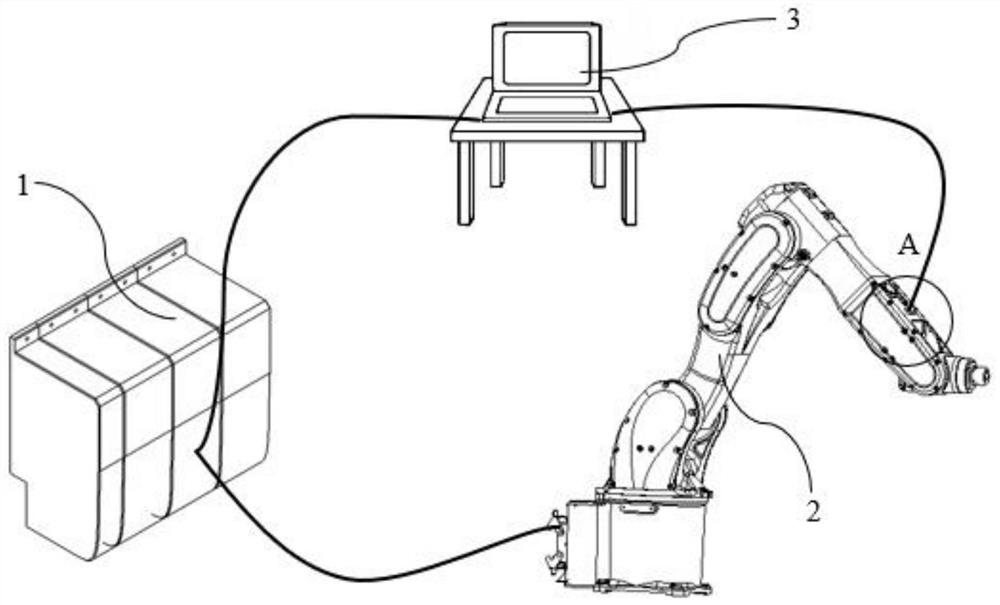

Method for measuring and evaluating jitter degree of tail end of industrial robot

The invention relates to the technical field of robot performance testing, in particular to a method for measuring and evaluating the jitter degree of the tail end of an industrial robot. The method comprises the following specific steps: S100, installing a vibration acceleration sensor; S200, determining a robot jitter test track; S300, collecting joint motor current data during operation of the robot through a driver by a computer, and collecting vibration acceleration data by the vibration acceleration sensor; S400, calculating a joint motor current fluctuation range value by the computer, and calculating a vibration acceleration result by the computer; S500, calculating the correlation between a current fluctuation range value result and a vibration acceleration test result; and S600, generating a robot jitter test report by the computer. Subjective evaluation of existing robot jitter is changed into objective quantitative measurement through the vibration acceleration sensor, the robot jitter degree can be quantitatively measured and described, collection is simple and convenient, the measurement time is short, the equipment cost is low, and the personnel requirement is low.

Owner:EFORT INTELLIGENT EQUIP CO LTD

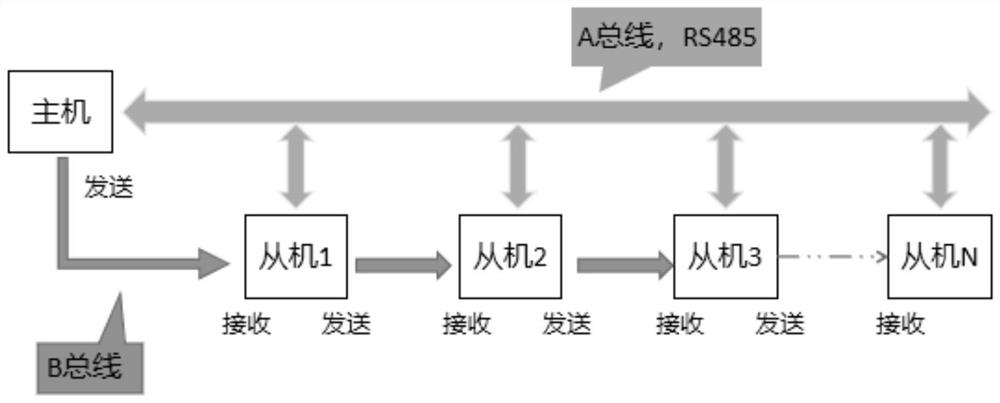

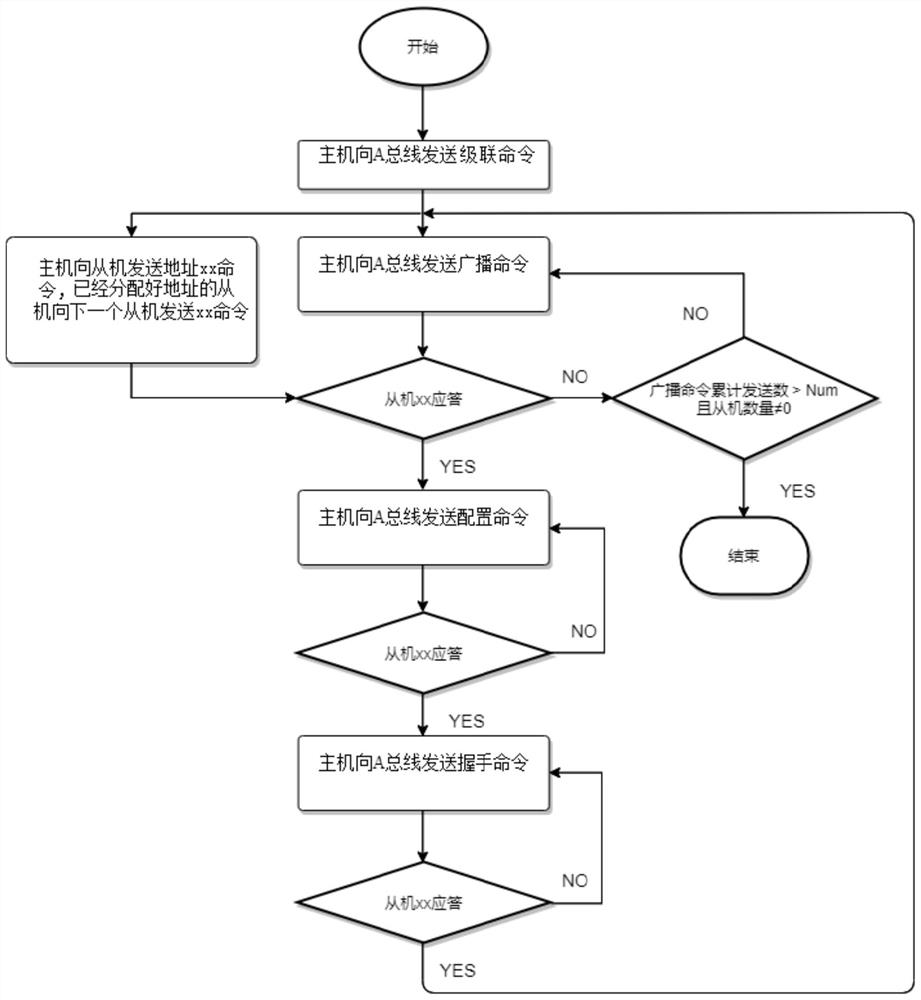

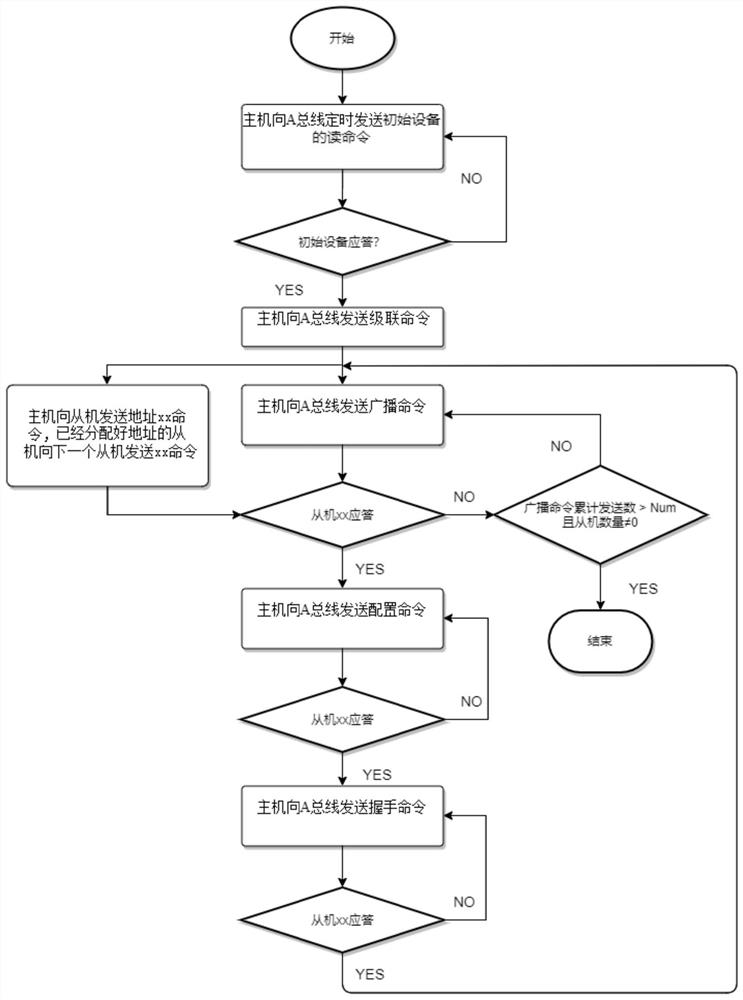

Bus address automatic allocation and identification method, electronic equipment, storage medium and program product

PendingCN114531422AIncrease flexibilityLow personnel requirementsElectric digital data processingBus networksEngineeringBus

The invention provides a bus address automatic allocation and identification method, which comprises the following steps that: a host sends a cascade command to a first bus, so that all slaves connected to the first bus are subjected to address reset; the host circularly and sequentially sends broadcast, configuration and handshake commands to the first bus and waits for response of the slave; according to a device connection sequence on the second bus, the host sends an address command to the first slave through the second bus, the first slave receiving the address command responds to the first bus, and after the first slave completes allocation, the first slave sends the address command to the second slave through the second bus, and the second slave receiving the address command responds to the first bus, and loop execution is carried out until all the slaves complete address configuration. The invention relates to an electronic device, a storage medium, and a program product. The method is flexible, low in requirement for field operation personnel and low in error rate, and the situation that equipment is lost due to a bus competition mode is avoided.

Owner:RENOGY NEW ENERGY CO LTD

Method for preparing LDE light source fluorescence powder and method for detecting fluorescent powder uniform degree

InactiveCN103268913AGuaranteed yieldEffective time is shortInvestigating moving fluids/granular solidsSemiconductor devicesFluorescenceMaterials science

The invention discloses a method for preparing LDE light source fluorescence powder and a method for detecting a fluorescent powder uniform degree, and belongs to the technical field of electrical components. The method for preparing the LDE light source fluorescence powder and the method for detecting the fluorescent powder uniform degree solve the problems that existing LDE light source fluorescence powder is large in preparation quantity and the uniform degree is difficult to detect. The method for preparing the LDE light source fluorescence powder is composed of a soaking step, a stirring step and a detecting step. The method for detecting the fluorescent powder uniform degree is composed of a sampling and liquid dropping step and an observing and judging step. According to the method for preparing the LDE light source fluorescence powder, stirring time can be greatly shortened through preparation of a small dose of the fluorescence powder and through still standing and soaking, and workload is effectively reduced. The method for detecting the fluorescent powder uniform degree is ordinary in required equipment and low in personnel requirement. The method for detecting the fluorescent powder uniform degree further has the advantages of being convenient to control and short in time required by detection, and hardly influencing valid duration of the LDE light source fluorescence powder.

Owner:浙江福森电子科技有限公司

Fry split charging device

InactiveCN102405866AEasy to operateLow personnel requirementsClimate change adaptationPisciculture and aquariaAtmospheric sciencesElectrical and Electronics engineering

The invention discloses a fry split charging device which is characterized by comprising a fry gauge, a fry bagger, a weighing device and an oxygen charging system, wherein the fry gauge is used for metering the fry quantity; the fry bagger is used for bagging well metered fries and water together; the weighing device is used for weighing the weight of the fries and the weight of the water; and the oxygen charging device is used for charging oxygen for the fries in a fry bucket and the bagged fries. The fry split charging device has the following beneficial effects that: the method is simple to operate; less personnel are required (the device can be operated by only one sitting person); the split charging is rapid, the split charging quality is high and the labor intensity is light; and the device is suitable for split charging in bulk.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

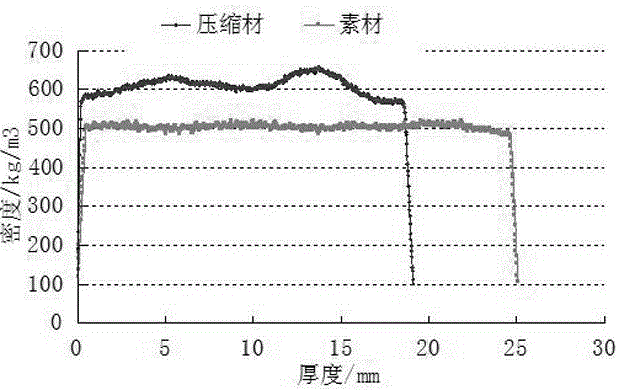

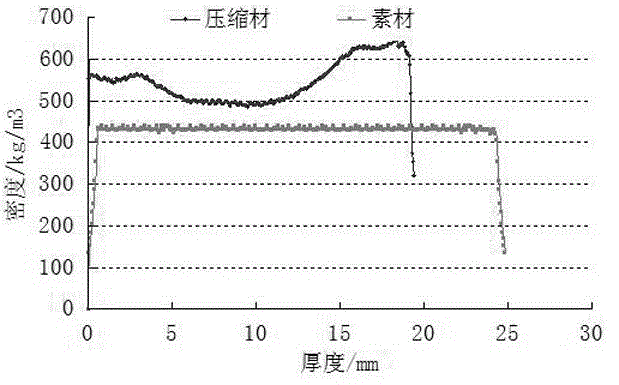

Integral reinforced solid wood section bar and manufacturing method thereof

ActiveCN103481348BSmall volume lossHigh strengthWood working apparatusFlat articlesSolid woodProcess engineering

The invention belongs to the technical field of wood function improvement and wood processing, and specifically discloses an integral reinforced solid wood profile and a manufacturing method thereof. The method comprises the following steps: under the condition of low moisture content (1-3%), the wood is subjected to integral compression treatment with low compression rate by adopting a heating and softening forming technology, so as to obtain an integral compressed material with uniform cross-sectional density. The method can effectively reduce the phenomenon of blasting and bubbling caused by excessive steam pressure inside the wood, greatly shorten the heat preservation time, and improve work efficiency. The overall compressed timber profile obtained by the method of the invention has good dimensional stability, is environmentally friendly and healthy, and can be used for manufacturing solid wood floors, solid wood furniture and as interior decoration materials.

Owner:江门健威家具装饰有限公司

Socket casting agent

InactiveCN111471288ASimple and efficient operationLow personnel and equipment requirementsPolymer chemistryMechanical properties of carbon nanotubes

The invention discloses a socket casting agent. The socket casting agent comprises a liquid component and a solid component, wherein the liquid component comprises unsaturated polyester resin and an accelerant; the solid component includes a powder reinforcement and an initiator. The liquid component and the solid component are prepared separately and are stored in respective containers separately. When in use, the liquid component and the solid component are fully stirred and uniformly mixed according to the proportion, and are cast into a socket within the gelation time. The casting agent provided by the invention can be operated at normal temperature, has good mechanical properties after being cured and molded, is tightly combined with a rope, has strong clamping force and is suitable for a hoisting or anchoring device at the end of the rope.

Owner:刘刚

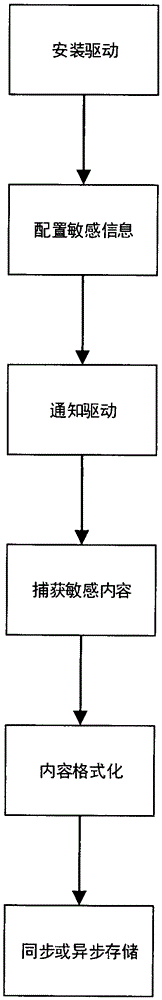

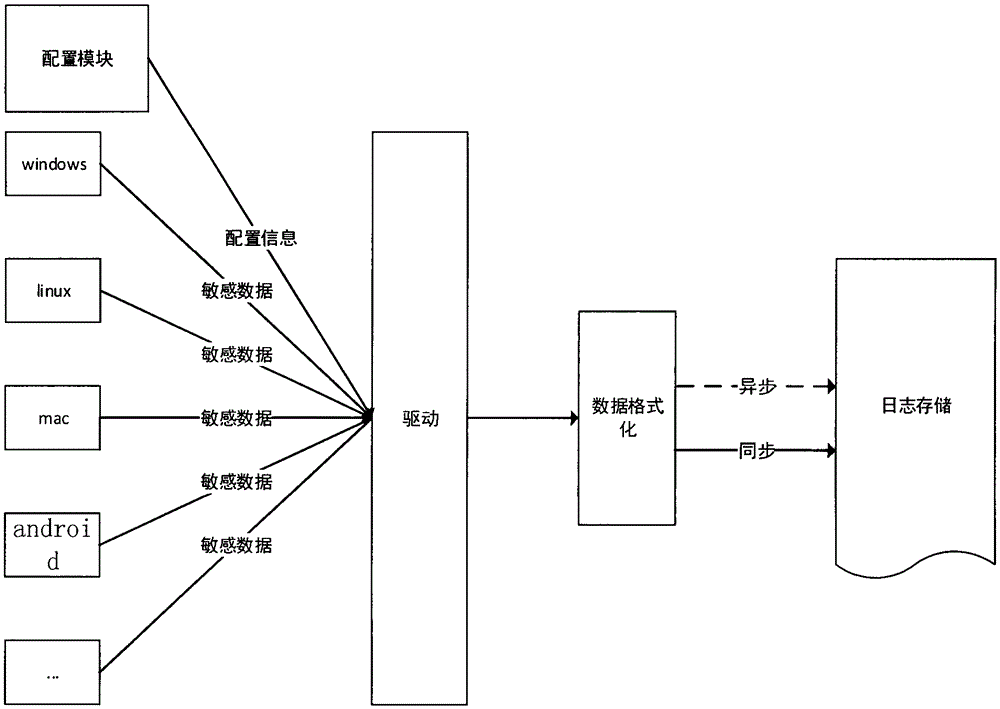

General file system log recording method and device

ActiveCN106815126ALow personnel requirementsShorten the timeHardware monitoringSpecial data processing applicationsData contentFile system

The invention discloses a general file system log recording method and device. The method comprises the following steps of providing a file driving of each platform operation system; capturing file change information; organizing the information into a log file. Through relevant functions of an encapsulation operation system or a file system, a user can directly utilize the generated log file to analyze the concerned data contents; the personnel requirements are reduced; a great amount of time is saved.

Owner:NANJING UNARY INFORMATION TECH

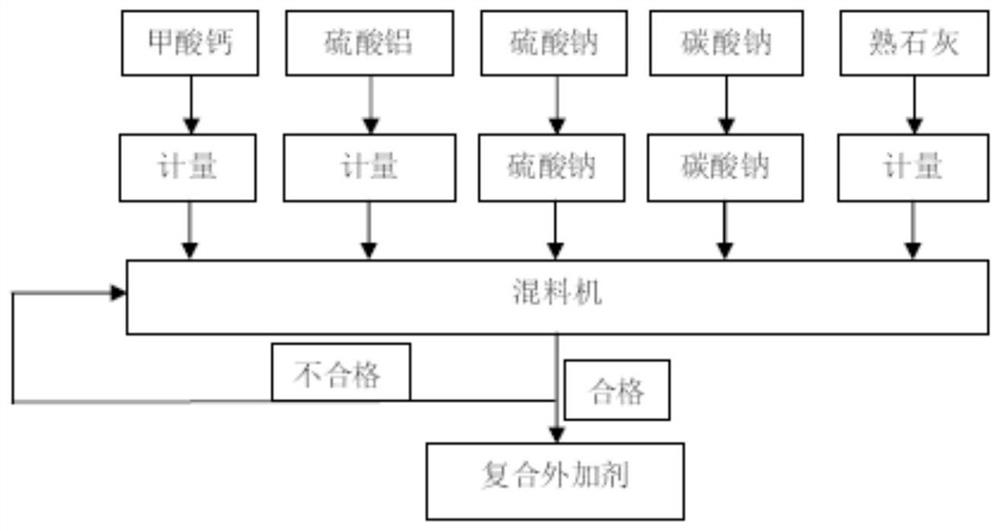

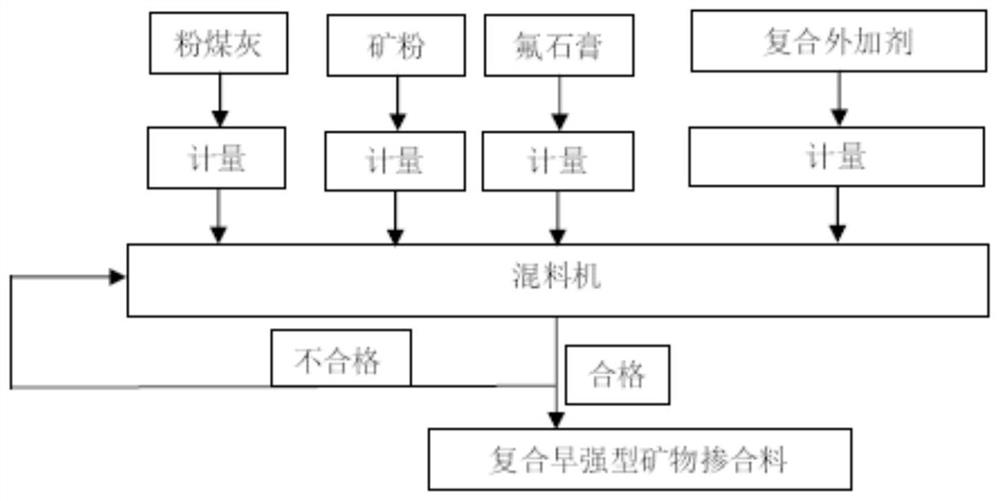

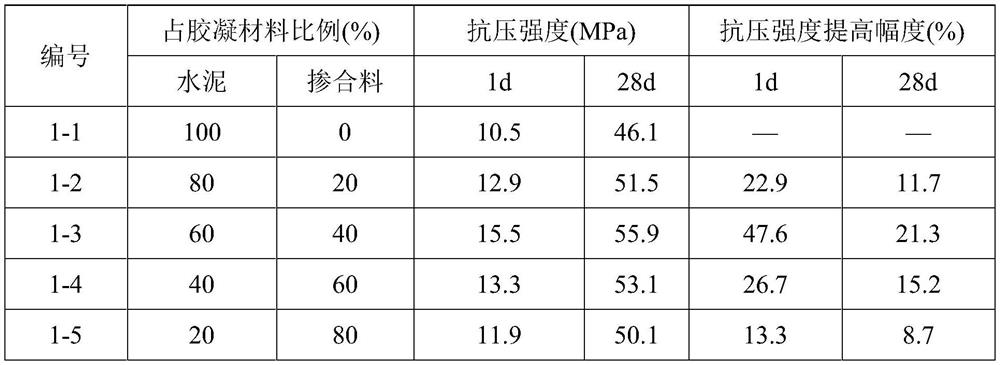

Composite early-strength mineral admixture, and preparation method and application thereof

ActiveCN113735481ARealize utilizationAvoid environmental pollutionSodium acid carbonateAluminium salts

The invention belongs to the technical field of building materials, and particularly relates to a composite early-strength mineral admixture, and a preparation method and application thereof. The composite early-strength mineral admixture comprises fly ash, mineral powder, fluorgypsum and a composite additive, wherein the mass ratio of the fly ash to the mineral powder to the fluorgypsum to the composite additive in the composite early-strength mineral admixture is (30-50): (30-50): (10-20): (10-20); and the composite admixture is prepared from, by weight, 20 to 30 parts of calcium formate, 20 to 30 parts of aluminum sulfate, 10 to 20 parts of sodium sulfate, 10 to 20 parts of sodium carbonate and 20 to 30 parts of slaked lime. The composite early-strength mineral admixture not only can realize the utilization of solid wastes and avoid environmental pollution, but also is beneficial to improving the compressive strength of cement concrete and improving the use performance of the concrete.

Owner:HENAN POLYTECHNIC UNIV

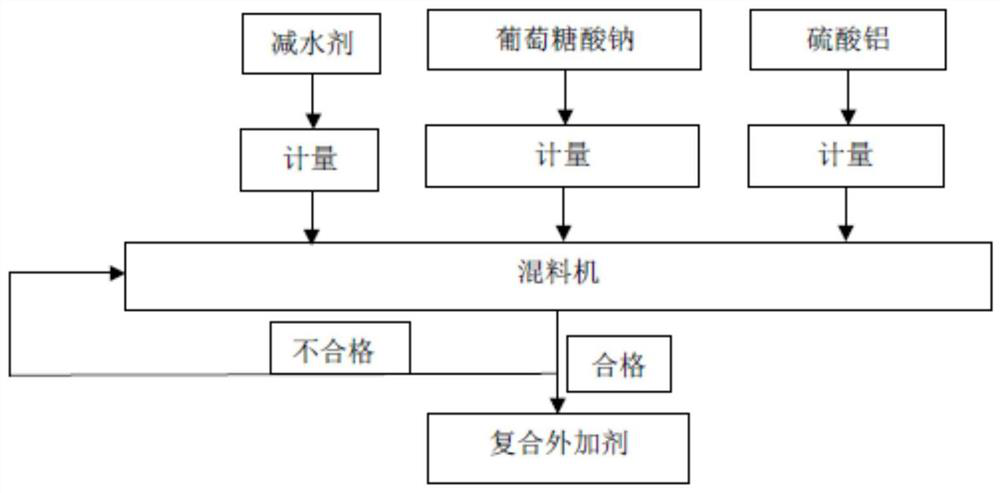

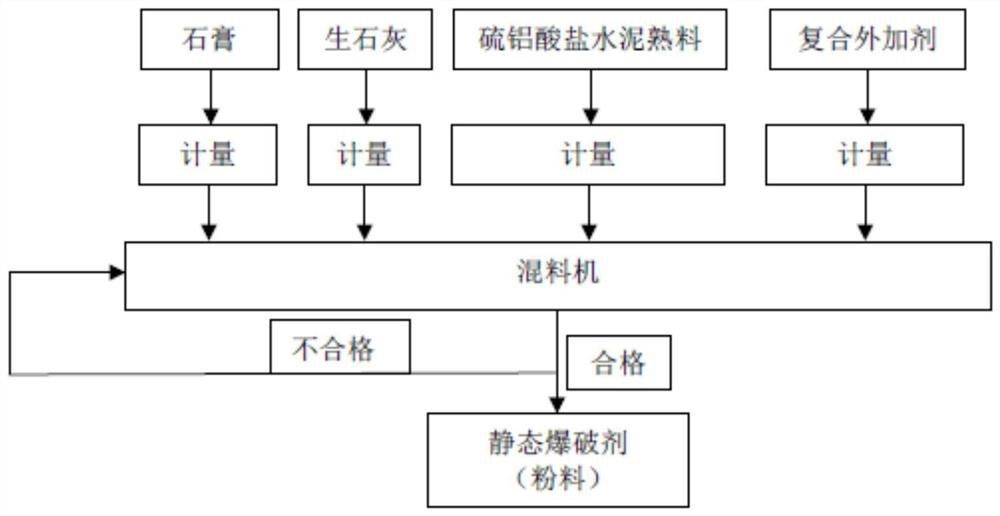

Sulphoaluminate cement and lime-based static blasting agent and preparation method thereof

The invention belongs to the technical field of mining, and particularly relates to a sulphoaluminate cement and lime-based static blasting agent and a preparation method thereof. The static blasting agent comprises sulphoaluminate cement clinker, quick lime, gypsum and a composite additive, the composite additive comprises a water reducing agent, aluminum sulfate and sodium gluconate; and the quick lime is obtained by normalizing and calcining. The sulphoaluminate cement and lime-based static blasting agent can obviously shorten the expansion starting time.

Owner:HENAN POLYTECHNIC UNIV

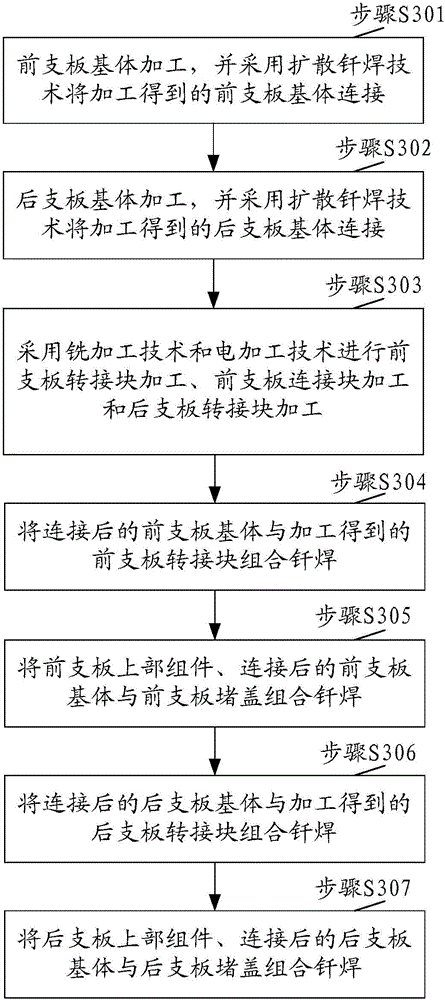

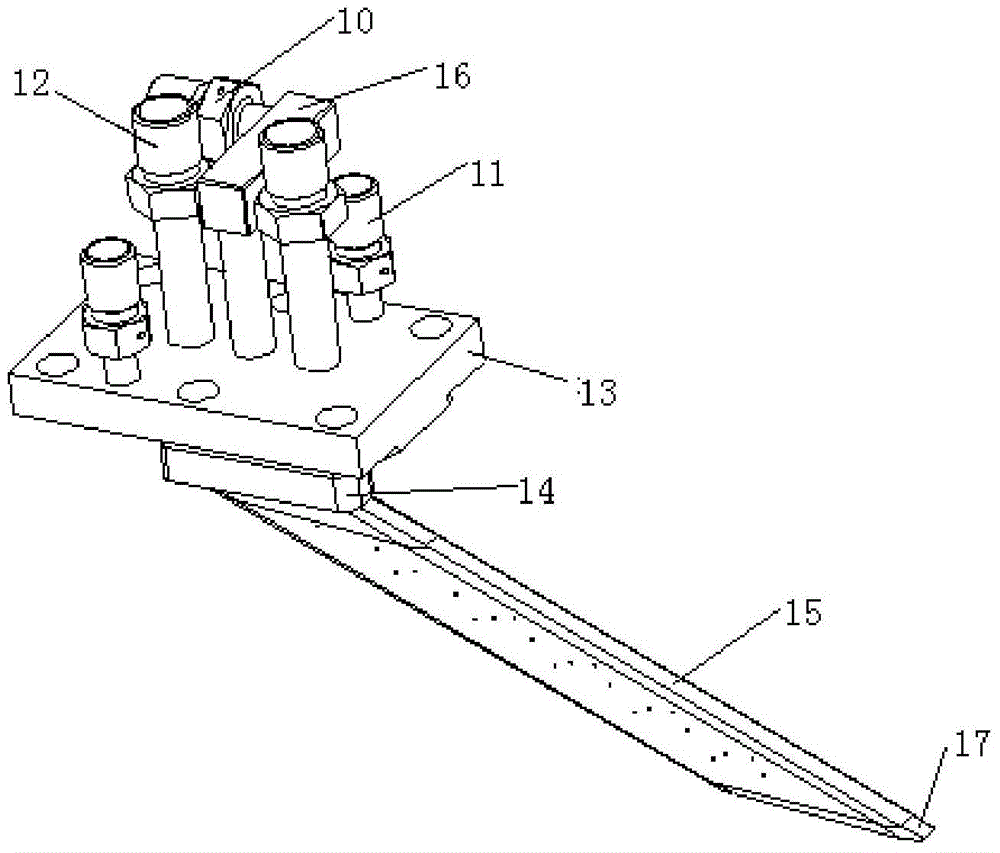

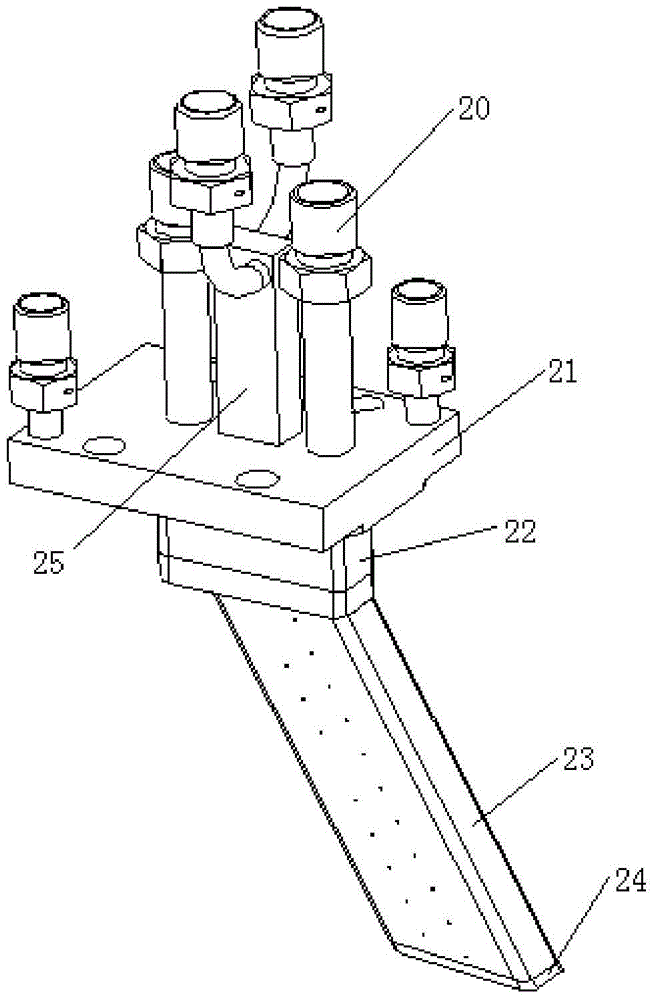

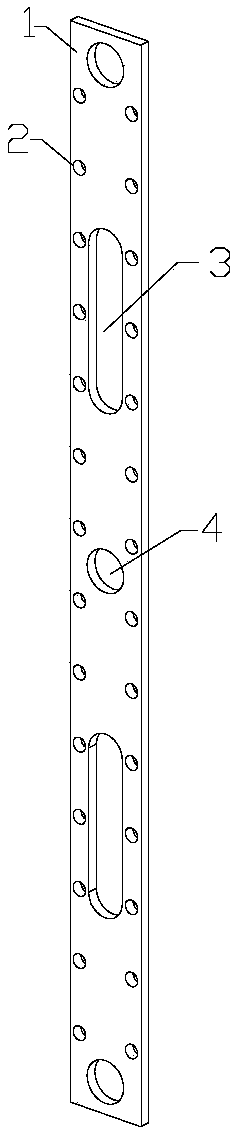

Manufacturing method for deep-hole members such as specially-shaped beams

The invention discloses a manufacturing method for deep-hole members such as specially-shaped beams. The method comprises the following steps of machining front support plate base bodies, and connecting the machined front support plate base bodies by virtue of a diffusion brazing technology; machining rear support plate base bodies, and connecting the machined rear support plate base bodies by virtue of the diffusion brazing technology; machining front support plate adapting blocks, front support plate connecting blocks and rear support plate adapting blocks by virtue of a milling machining technology and an electric machining technology; brazing the connected front support plate base bodies and the machined front support plate adapting blocks in a combined manner; brazing front support plate upper components, the connected front support plate base bodies and front support plate plug covers in a combined manner; brazing the connected rear support plate base bodies and the machined rear support plate adapting blocks in a combined manner; and brazing rear support plate upper components, the connected rear support plate base bodies and rear support plate plug covers in a combined manner.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

Shear wall connecting structure by using steel pipe occlusion mode and manufacturing and assembling method

PendingCN108104307ASimple and efficient operationLow requirements on personnel and environmentWallsProtective buildings/sheltersSteel platesSteel tube

The invention relates to the field of fabricated concrete structures, in particular to a shear wall connecting structure by using a steel pipe occlusion mode and a manufacturing and assembling method.Two shear walls assembled through the structure only can be assembled from the horizontal direction. Disassembling is conducted at the connecting position between the two shear walls, and a prefabricated outer pipe wall and a prefabricated inner pipe wall are manufactured, wherein side surface steel plates and prefabricated wall steel bars are connected through reserved steel bar penetrating holes, and steel plate rigidity weakening holes are reserved; outer sleeve steel pipes and embedded steel pipes are welded to the side surface steel plates of the two prefabricated walls correspondingly,and reserved grouting holes are formed in the outer sleeve steel pipes; and the outer sleeve steel pipes and the embedded steel pipes are in abut joint through occlusion, and then connecting of the two prefabricated walls is completed to form a whole. According to the shear wall connecting structure by using the steel pipe occlusion mode and the manufacturing and assembling method, the outer sleeve steel pipes and the embedded steel pipes are arranged on the side walls of the shear walls, the outer sleeve steel pipes extend into the embedded steel pipes through the embedded steel pipes, and grouting is conducted at the connecting positions of the outer sleeve steel pipes and the embedded steel pipes, so that connecting pieces of the outer sleeve steel pipes and the embedded steel pipes arecompact, and horizontal connecting of the prefabricated shear walls is achieved. According to the structure, components are simple and easy to machine, and the assembly process is simple.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com