Program programming tooling system

A program and tooling technology, which is applied in the field of program programming tooling system, can solve the problems of raising the educational level of operators and labor costs, error-prone operations, operator fatigue, etc., and achieve the reduction of personnel requirements and production equipment requirements. Easy and scientific, the effect of personal safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

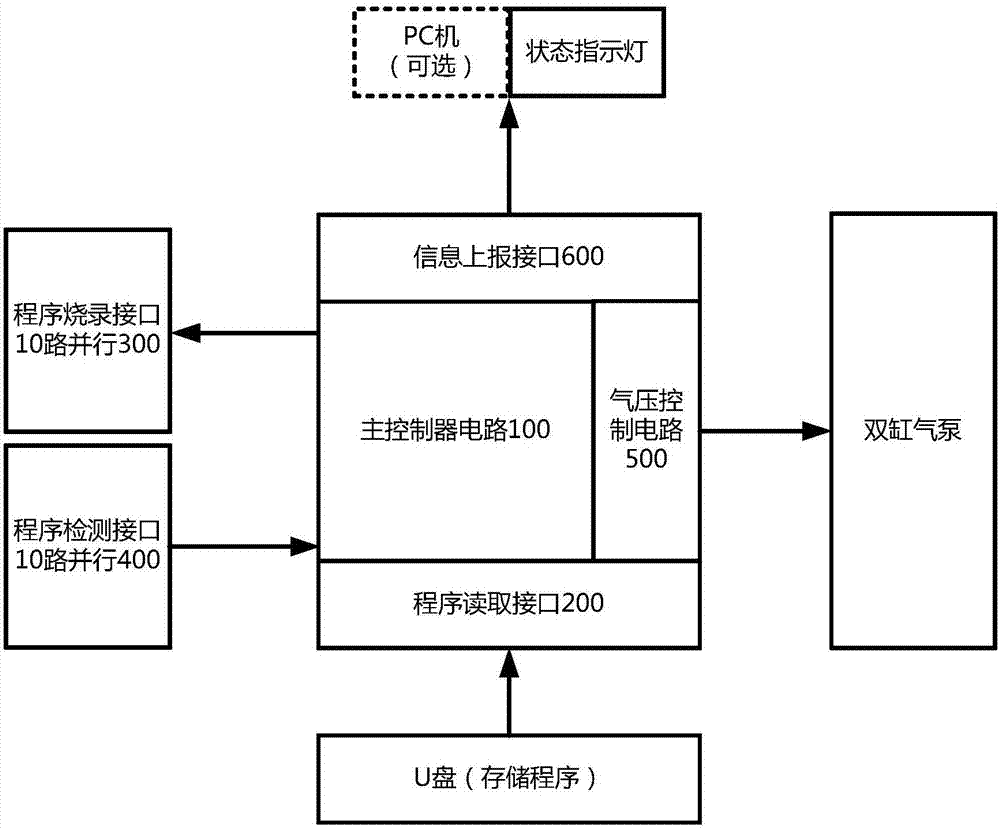

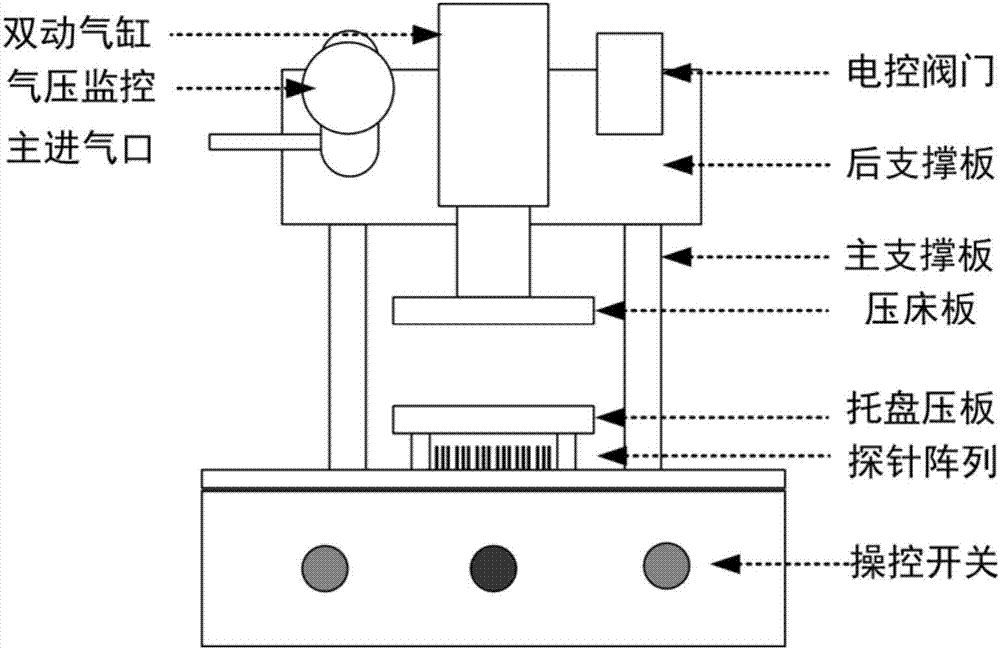

[0032] Such as figure 1 As shown, the program burning tooling system of the embodiment of the present invention includes: a tooling platform, a main controller circuit 100, a program reading interface 200, a program burning interface 300, a program detection interface 400, an information reporting interface 600 and an air pressure control circuit 500. It should be noted that the main controller circuit 100 is the core of the entire tooling system, and is used to realize the management and implementation of various cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com