Composite early-strength mineral admixture, and preparation method and application thereof

A mineral admixture and early-strength technology, applied in the field of building materials, can solve problems such as solid waste polluting the environment and concrete performance deterioration, and achieve low requirements for production equipment and personnel, high compressive strength, and short production cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

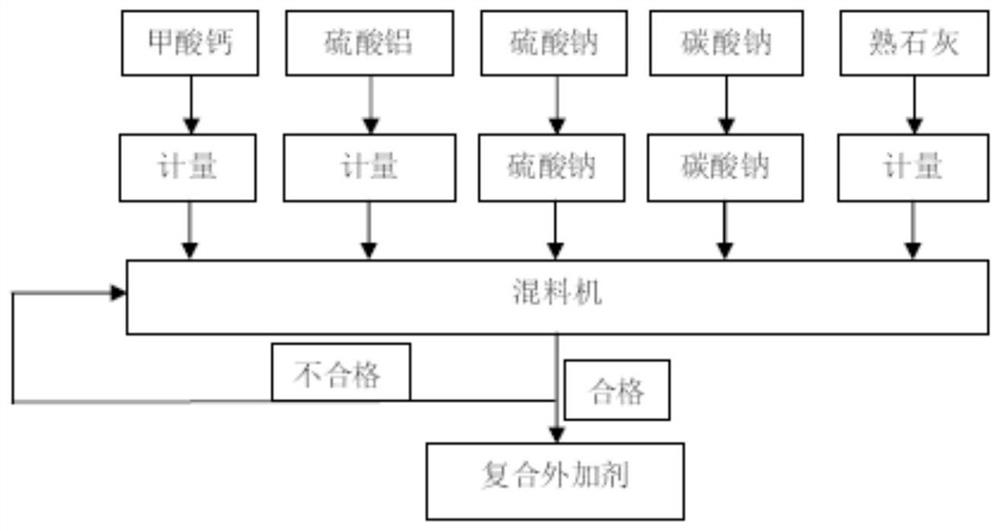

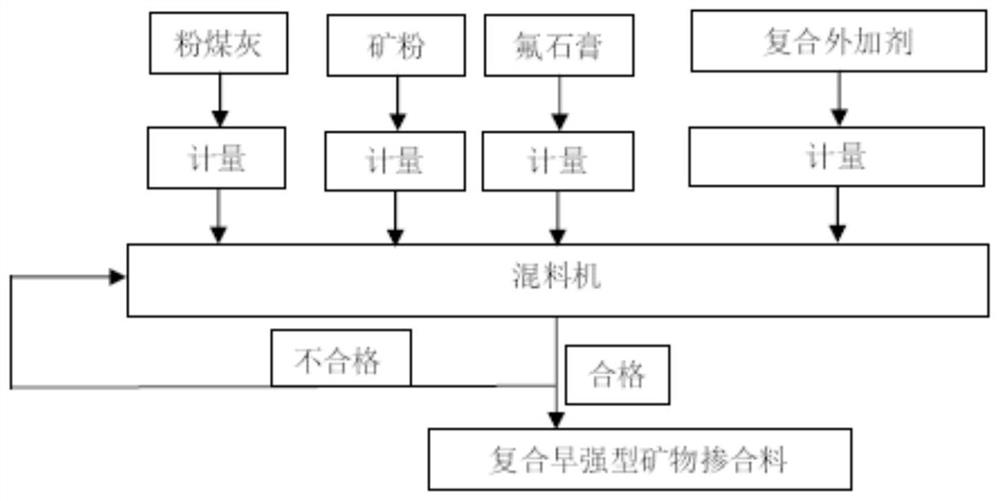

[0049] The preparation method of composite early-strength type mineral admixture of the present invention: comprises the following steps:

[0050] Step S1, mixing the calcium formate, aluminum sulfate, sodium sulfate, sodium carbonate and slaked lime uniformly in proportion to obtain the composite admixture;

[0051] Step S2, uniformly mixing the fly ash, mineral powder, fluorogypsum and the composite admixture in proportion to obtain the composite early-strength mineral admixture.

[0052] In the preferred embodiment of the preparation method of the composite early-strength mineral admixture of the present invention, in the step S1, calcium formate, aluminum sulfate, sodium sulfate, sodium carbonate and slaked lime are added in the mixer according to the proportion and mixed uniformly, the ratio Surface area up to 350m 2 / kg, with reference to the national standard "Concrete Admixture" GB 8076-2008 test, after passing the test, the composite admixture is obtained (see the ac...

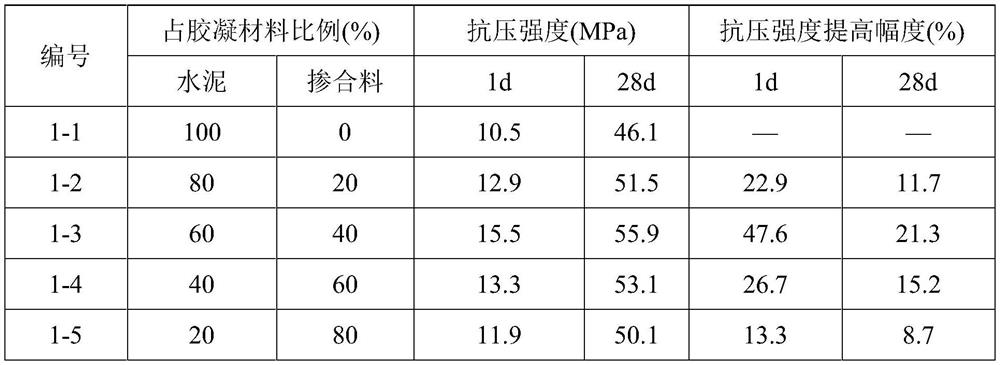

Embodiment 1

[0073] Composite early-strength type mineral admixture comprises in the present embodiment: fly ash 4000g, mineral powder 3500g, fluorogypsum 1000g and composite admixture 1500g; Wherein, composite admixture comprises calcium formate 2500g, aluminum sulfate 2500g, sodium sulfate 1500g, Sodium carbonate 1500g and slaked lime 2000g.

[0074] The preparation method of the composite early-strength type mineral admixture of the present embodiment may further comprise the steps:

[0075] Step S1, add 2500g of calcium formate, 2500g of aluminum sulfate, 1500g of sodium sulfate, 1500g of sodium carbonate, and 2000g of slaked lime into the mixer and mix evenly, and the specific surface area reaches 350m 2 / kg, refer to the national standard "Concrete Admixture" GB 8076-2008 test, and get the compound admixture after passing the test;

[0076] Step S2, add 4000g of fly ash, 3500g of mineral powder, 1000g of fluorine gypsum, and 1500g of composite admixture into the mixer and stir until...

Embodiment 2

[0084] The difference from Example 1 is that the raw material components of the composite early-strength mineral admixture are different, specifically: including 3000g of fly ash, 4000g of mineral powder, 1500g of fluorogypsum and 1500g of composite admixture; wherein, the composite admixture includes 2000g of calcium formate , aluminum sulfate 3000g, sodium sulfate 1000g, sodium carbonate 1000g and slaked lime 3000g.

[0085] The preparation method of the composite early-strength type mineral admixture of the present embodiment: same as embodiment 1.

[0086] Application of the composite early-strength mineral admixture of this embodiment: Portland cement is used as the cementitious material 1; Portland cement is mixed with the composite early-strength mineral admixture of this embodiment according to different proportions, Prepare cementitious material 2 (the cementitious material 2 contains Portland cement 80wt% and the composite early-strength type mineral admixture 20wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com