Shear wall connecting structure by using steel pipe occlusion mode and manufacturing and assembling method

A technology for connecting structures and shear walls, applied to walls, building components, building structures, etc., to achieve the effects of low requirements for personnel and the environment, good energy consumption capacity, and high assembly rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

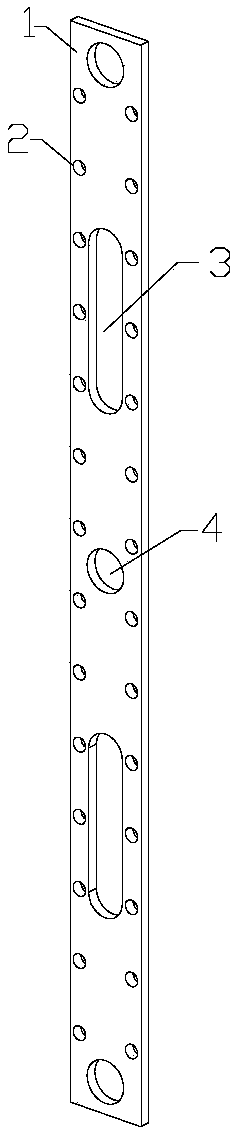

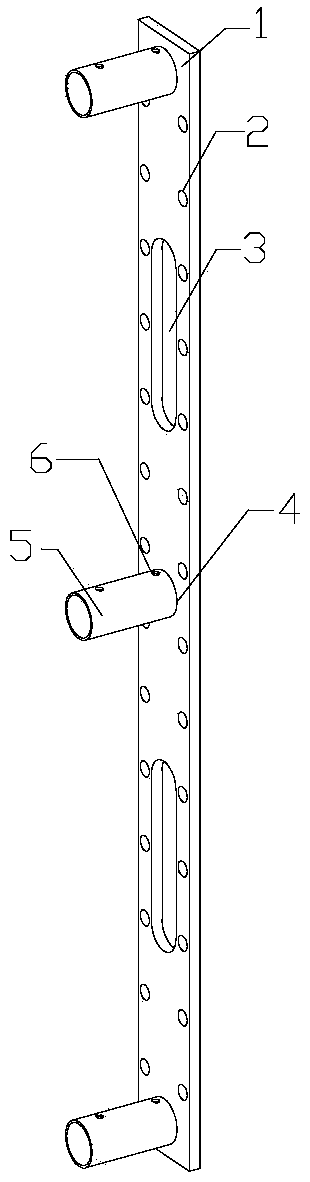

[0042] Such as Figure 1-Figure 15 As shown, the steel pipe occluding method shear wall connection structure, manufacturing and assembly methods of the present invention are as follows:

[0043] (1) The production process of prefabricated steel pipe wall with outer jacket

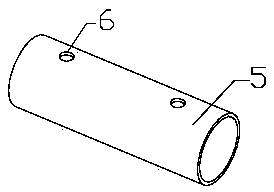

[0044] ① such as Figure 1-Figure 3 As shown, the outer steel pipe 5 is welded to the side steel plate 1, in which: the side steel plate 1 is provided with a reserved steel hole 2 along the longitudinal direction, the side steel plate 1 is symmetrically provided with weakening steel plate rigidity holes 3, and the middle and both ends of the side steel plate 1 are respectively opened The steel pipe connection hole 4 is reserved; the outer steel pipe 5 is set at the reserved steel pipe connection hole 4, and the side of the outer steel pipe 5 is provided with a reserved grouting hole 6.

[0045] Among them, the specifications of the outer steel pipe 5 should be determined by the vertical shear force transmitted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com