Method for preparing LDE light source fluorescence powder and method for detecting fluorescent powder uniform degree

A fluorescent powder and configuration method technology, applied in the direction of testing moving fluid/granular solid, electrical components, circuits, etc., can solve the problem of low preparation efficiency, achieve the effect of reducing workload, ensuring effectiveness, and ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

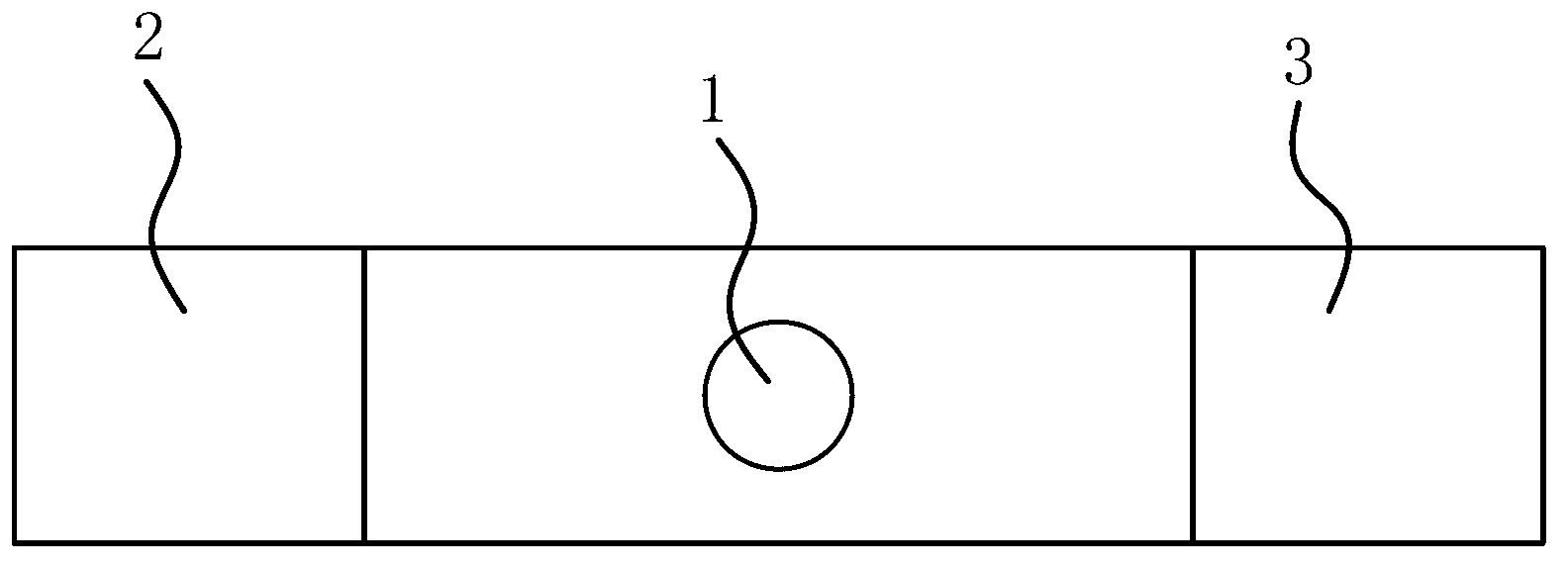

Image

Examples

Embodiment 1

[0034] Soaking is to add all the raw materials in the beaker first, and then let it stand for soaking. The raw materials of different LDE light source phosphor powders may be slightly different, but the raw materials of LDE light source phosphor powders are mainly composed of phosphor powder, epoxy resin glue and some auxiliary materials. As a preference, when adding raw materials, first add 3 grams of fluorescent powder into the beaker, and then add 3 grams of epoxy resin glue; and the auxiliary materials can be added before standing and soaking. The weight of the auxiliary material is only 0.08g-0.12g; the weight of the auxiliary material added this time is 0.1g.

[0035] When the epoxy resin glue is added, the phosphor powder is flushed, and the phosphor powder is mixed with the epoxy resin glue to produce a pre-mixed effect. In order to increase the pre-mixing effect, you can add epoxy resin glue and then stir for two or three circles; and before adding epoxy resin glue, ...

Embodiment 2

[0043]Soaking is to first add 3 grams of fluorescent powder to the beaker, add 0.08 grams of auxiliary materials, and then add 3 grams of epoxy resin glue. The soaking time is 1.5 minutes. Stirring was continued in a clockwise direction for 4 minutes.

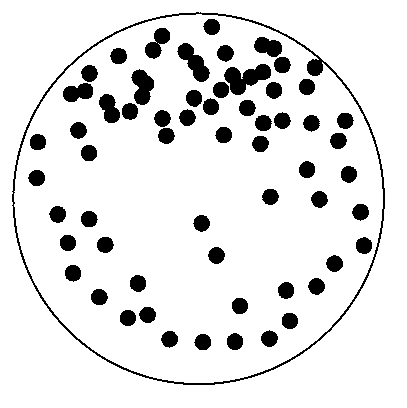

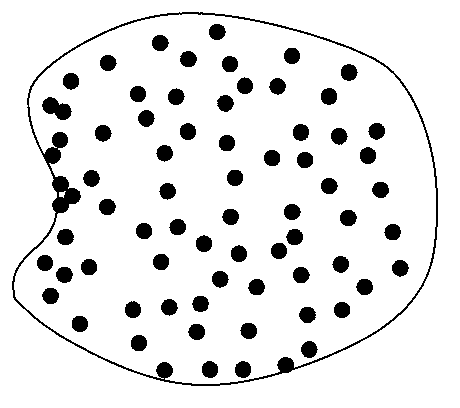

[0044] The uniformity of the fluorescent powder in the fluorescent powder is detected and the probability of directly meeting the requirements is about 65%. If the requirements are not met, continue to stir and test in turn. The stirring time in this step is 4 minutes each time; the probability of meeting the requirements is about 99% after re-testing; the phosphor powder that still does not meet the requirements is given up.

Embodiment 3

[0046] For soaking, first add 5 grams of fluorescent powder to the beaker, then add 5 grams of epoxy resin glue; finally add 0.12 grams of auxiliary materials. The soaking time is 3 minutes.

[0047] Stirring is to stir the above raw materials with glass rods to form fluorescent powder. Stirring was continued in a counterclockwise direction for 6 minutes.

[0048] The uniformity of the fluorescent powder in the fluorescent powder is detected and the probability of directly meeting the requirements is about 98%. If the requirements are not met, continue to stir and test in turn. The stirring time in this step is 4 minutes each time; the probability of meeting the requirements is about 98% in the re-test; the preparation of phosphors that still do not meet the requirements is abandoned.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com