Pumping control system and method based on dynamic level and casing pressure

A technology of control system and dynamic liquid surface, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems of high labor cost, poor control effect, and inability to maintain the efficiency of the pumping unit at the highest state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

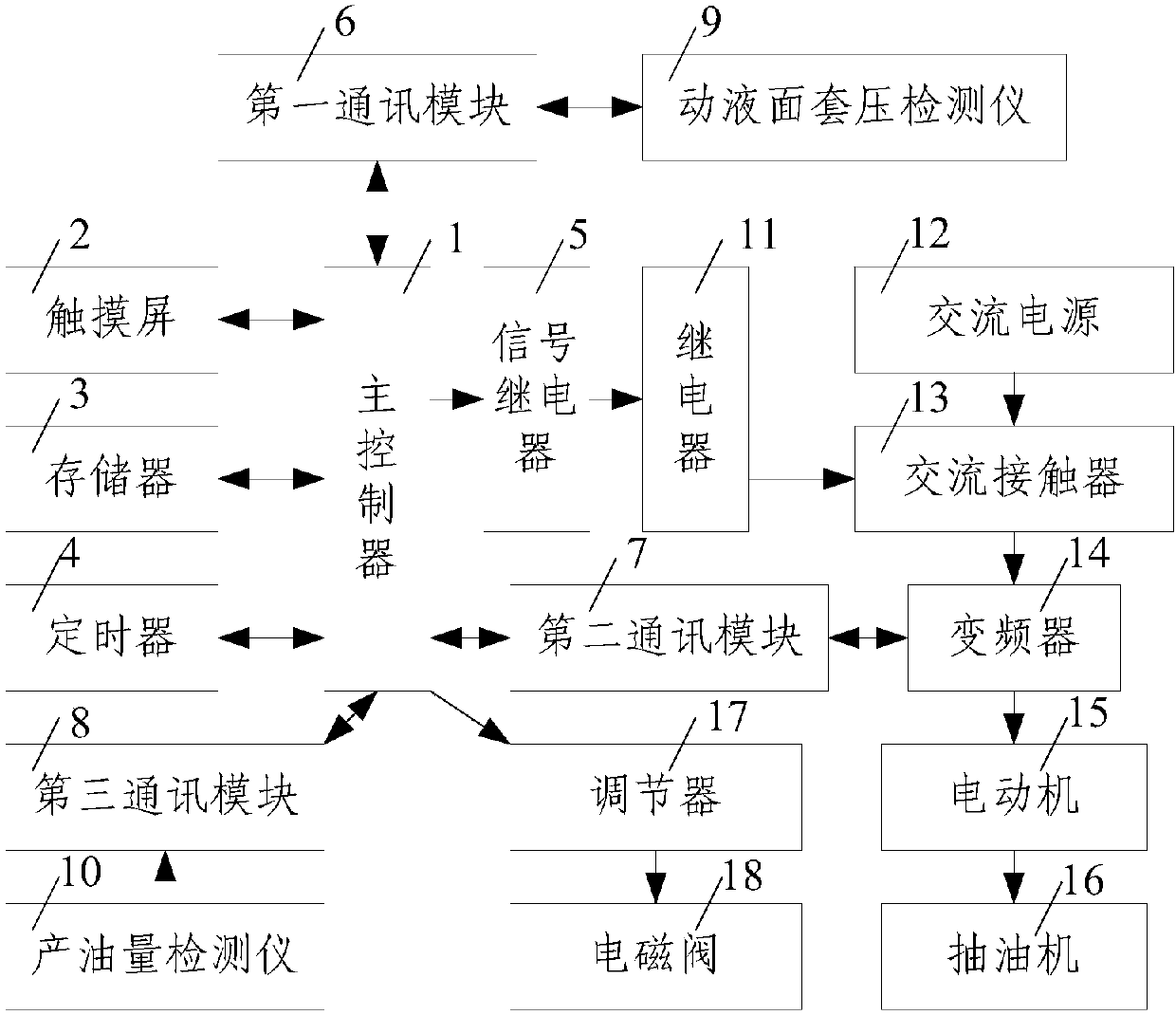

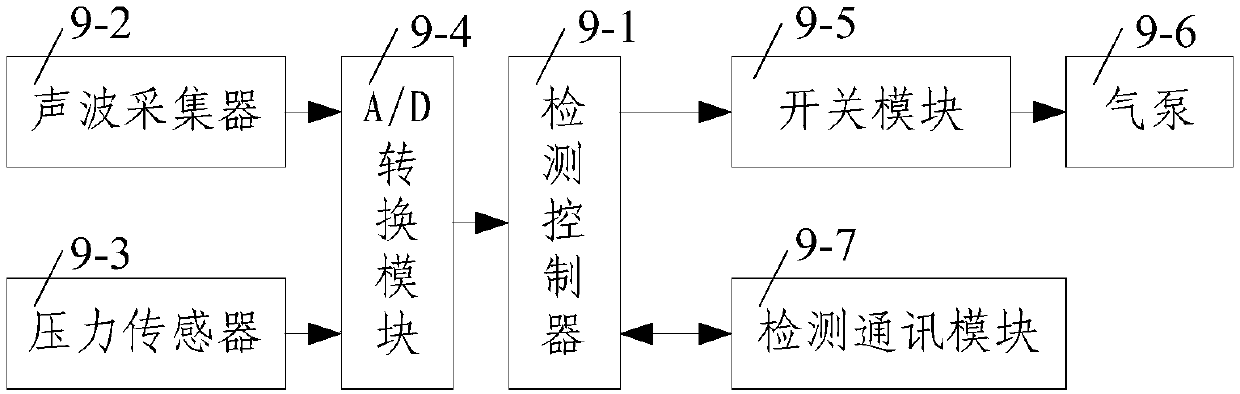

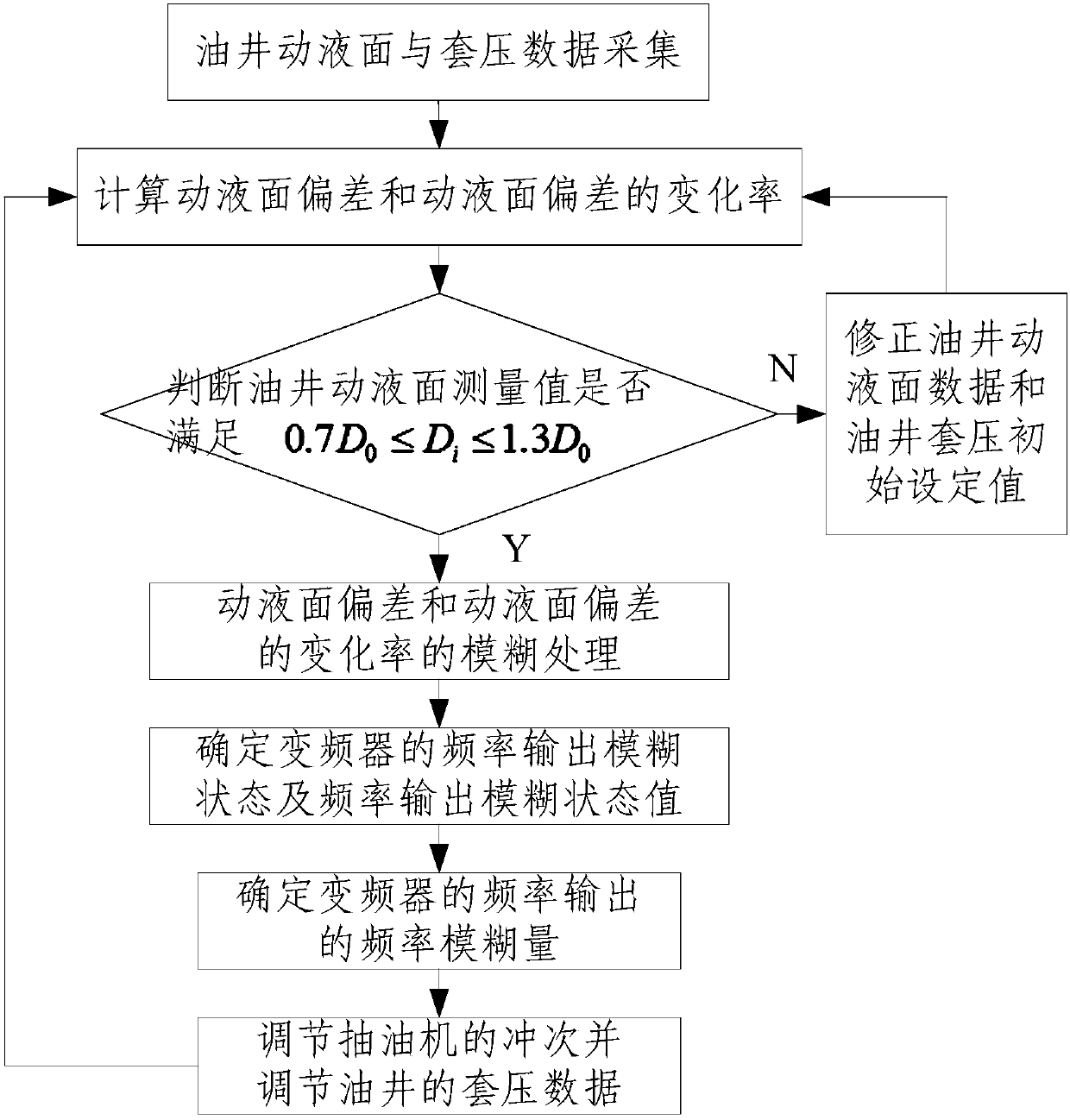

[0055] like figure 1 and figure 2 As shown, the oil pumping control system based on the dynamic fluid level and casing pressure of the present invention includes a main control platform and an oil production detector 10 installed on the oil storage tank for detecting the oil pumping rate, and is installed on the The oil well head is used to detect and detect the dynamic liquid level casing pressure detector 9 of the data in the oil well, the oil pumping adjustment mechanism used to control the oil pumping efficiency of the pumping unit 16, and the solenoid valve 18 used to control the casing annular pressure. The master control platform includes a master controller 1 and a touch screen 2, a memory 3 and a timer 4 that are all connected to the master controller 1, and the output terminal of the master controller 1 is connected with a regulator 17 for controlling the opening degree of the solenoid valve 18 and for Drive the signal relay 5 of the oil pumping adjustment mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com