Comprehensive mechanized coal mining surface ended bracket pushing device

A technology of fully mechanized mining face and end support, which is applied in the field of end support pushing device of fully mechanized mining face, can solve the problems of the width of the roadway not meeting the specified requirements, difficult to advance smoothly, affecting the expansion and contraction of the push rod, etc. Unsafe production factors, support strength guarantee, and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

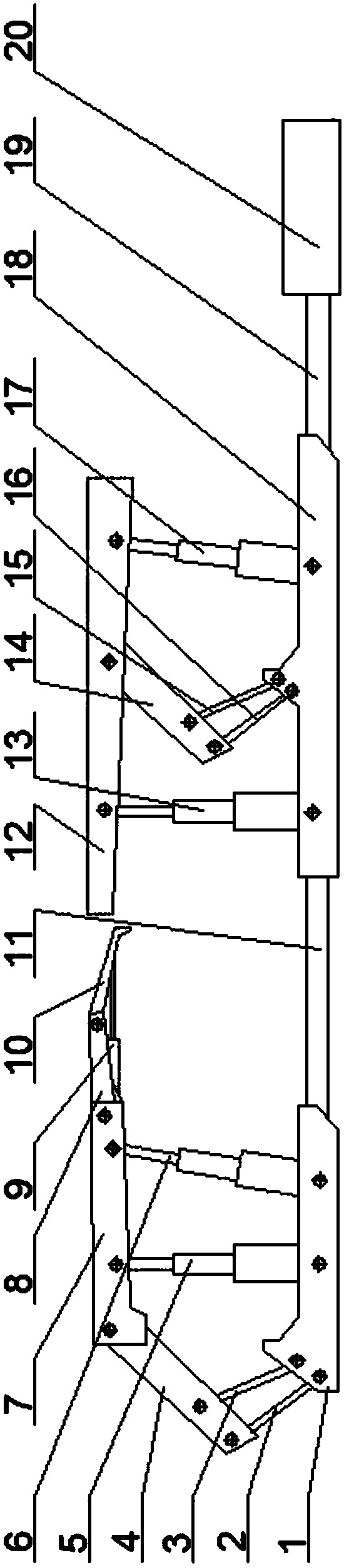

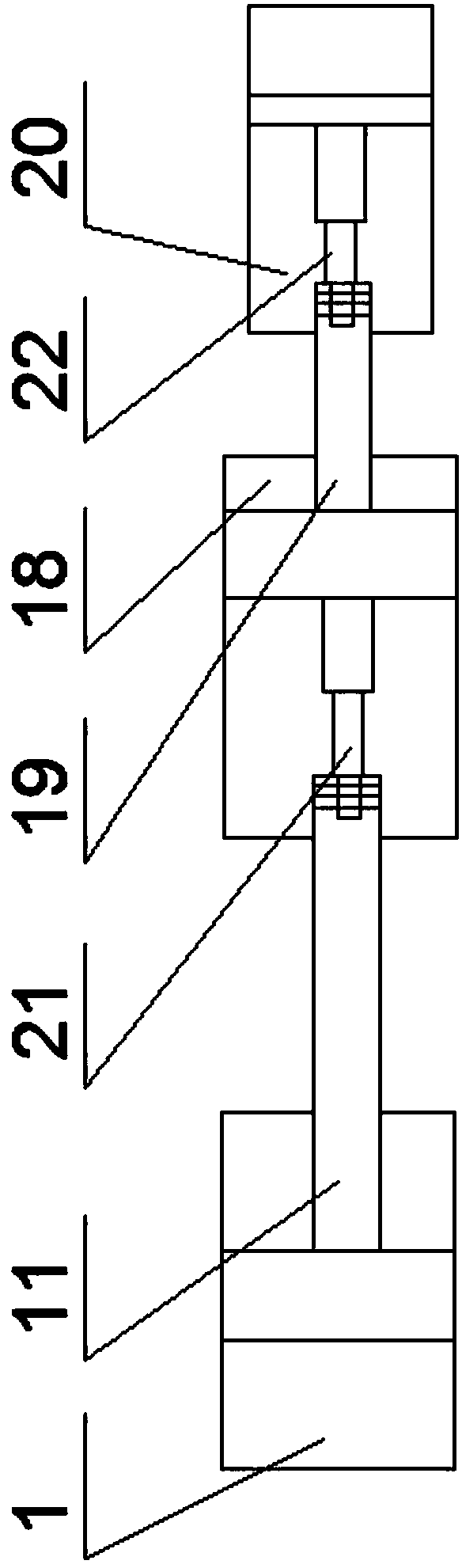

[0015] figure 1 with figure 2 Show the specific embodiment of the present invention: a fully mechanized mining face end bracket pushing device, including front bracket, rear bracket, pushing jack 21, push rod 11, pushing rod 19 and scraper conveyor head base 20, the The front bracket and the rear bracket are four-link supporting hydraulic supports. The four-bar linkage mechanism of the front bracket is installed between the columns of the front bracket, and the four-bar linkage mechanism of the rear bracket is installed at the rear of the rear bracket. The front column of the front bracket 6 Hinged with front support rear column 5 and front support top beam 7 and front support base 1, cover beam 4, front support front link 3, front support rear link 2 are connected with front support top beam 7 and front support base 1 Hinged to form a four-bar linkage, installed between the front column 6 of the front bracket and the rear column 5 of the front bracket, the front column 17 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com