A high-pressure explosion-proof gear pump housing

A gear pump, explosion-proof type technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of inconvenient connection of booster gear pumps, unclean flow channel cleaning, increased fluid temperature rise, etc., to avoid Fluid energy loss and flow pulsation, simple structure, and the effect of reducing fluid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

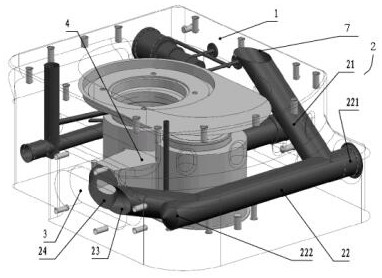

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

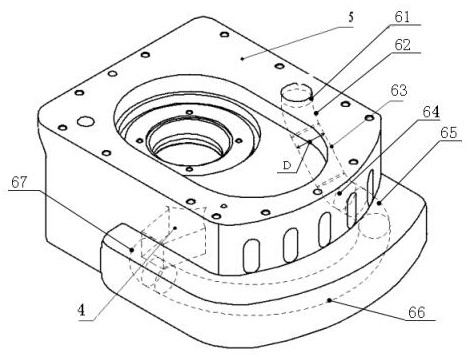

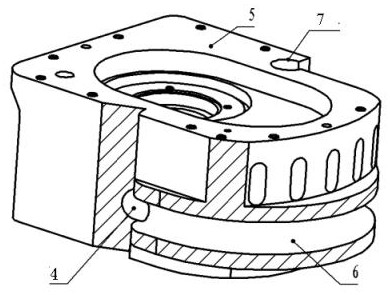

[0030] Example. A high-pressure explosion-proof gear pump housing, constituted as follows Figure 2-6 The housing main body 5 shown is included, and the oil passage 6 is arranged inside the housing main body 5; the oil passage 6 includes a No. 1 flow passage 61, and one end of the No. 1 flow passage 61 is provided with an oil passage inlet 7, The other end is connected with the second flow channel 63 through the first transition flow channel 62, the second flow channel 63 is connected with the third flow channel 66 through the second transition flow channel 64 and the third transition flow channel 65, and the third flow channel 66 is connected with the third flow channel 66. The fourth transition channel 67 is connected, and the fourth transition channel 67 is connected to the inlet 4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com