Magnetron

A technology of magnetron and circular tube, applied in the field of magnetron, can solve the problems of insufficient heat dissipation of sleeve, complicated processing of heat dissipation components, loss of heat dissipation effect of heat dissipation plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

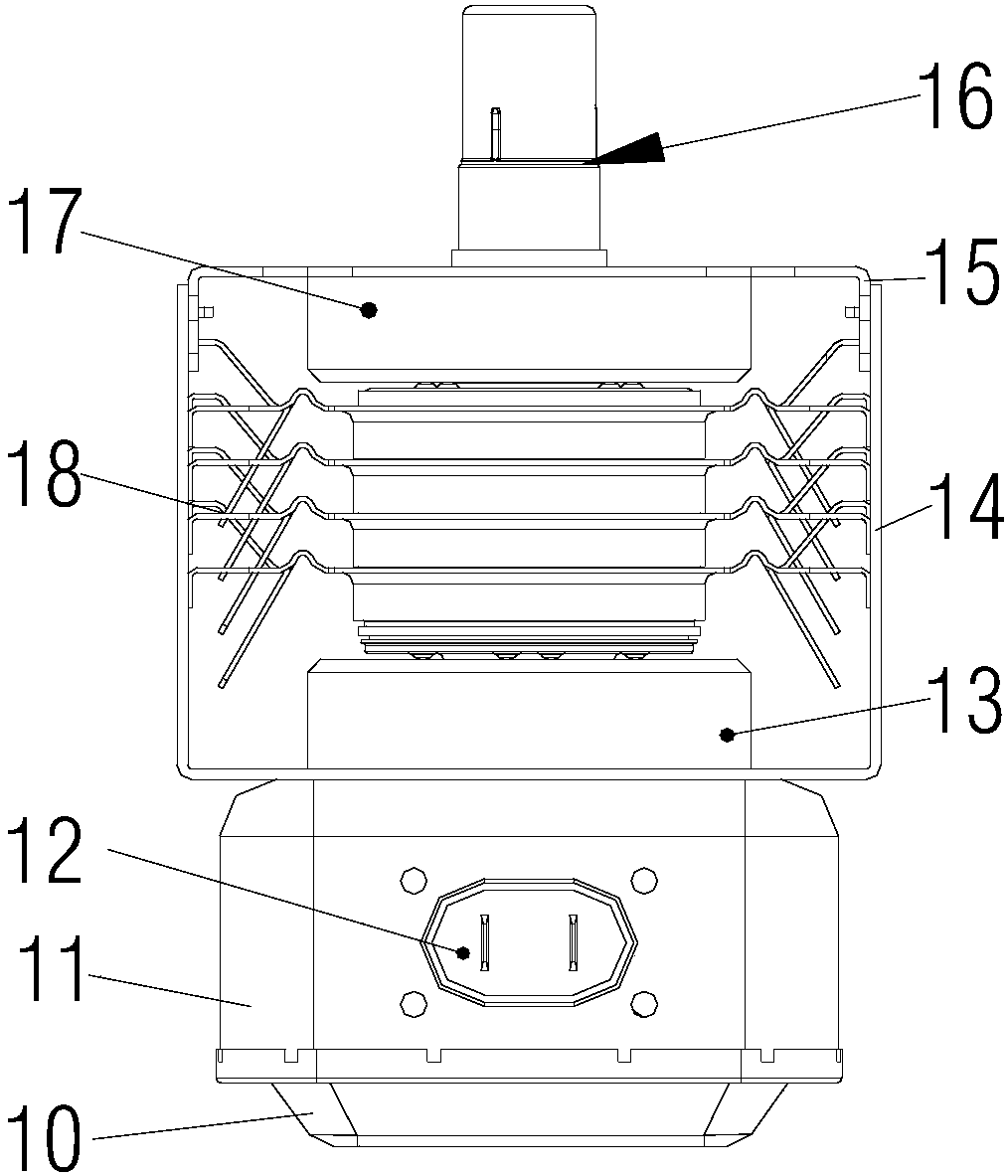

[0035] In the present invention, unless stated to the contrary, the used orientation words such as "up, down, left, right" usually refer to the directions shown in the drawings or to the vertical, vertical or neutral directions. Words are used to describe the mutual positional relationship of each component upwardly. "Inside and outside" means that relative to the shell of the part, the space covered by the shell is "inside", and the outside of the shell is "outside".

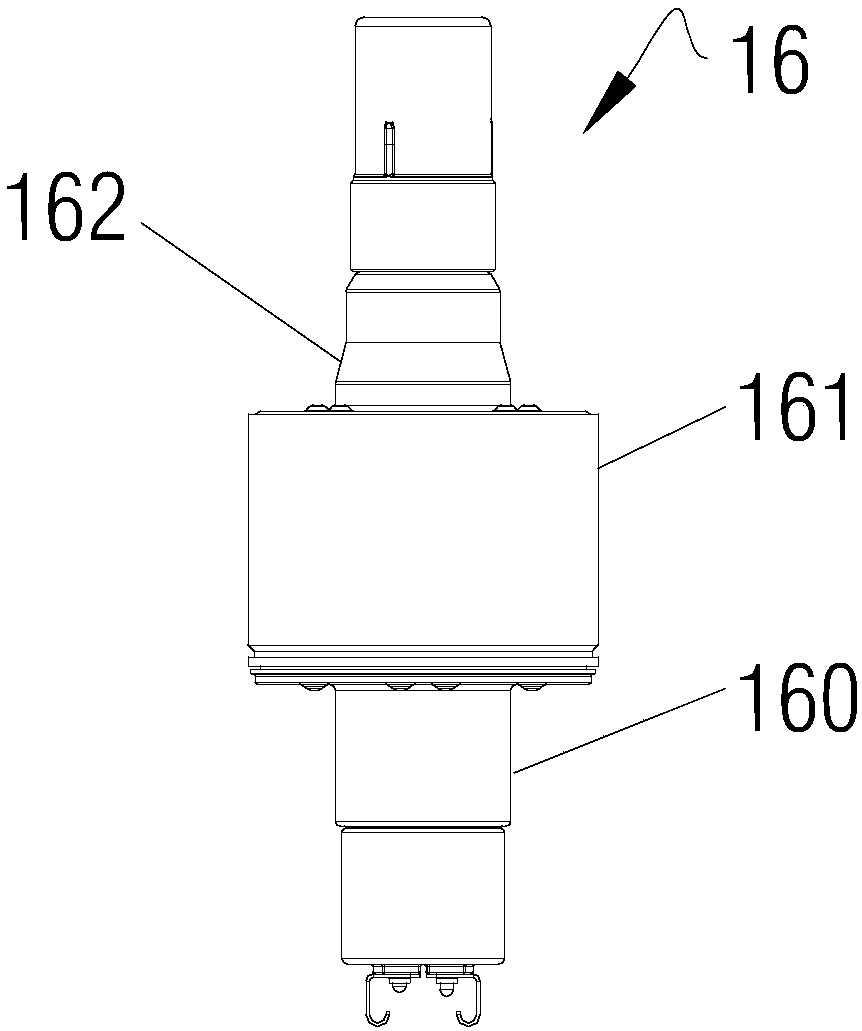

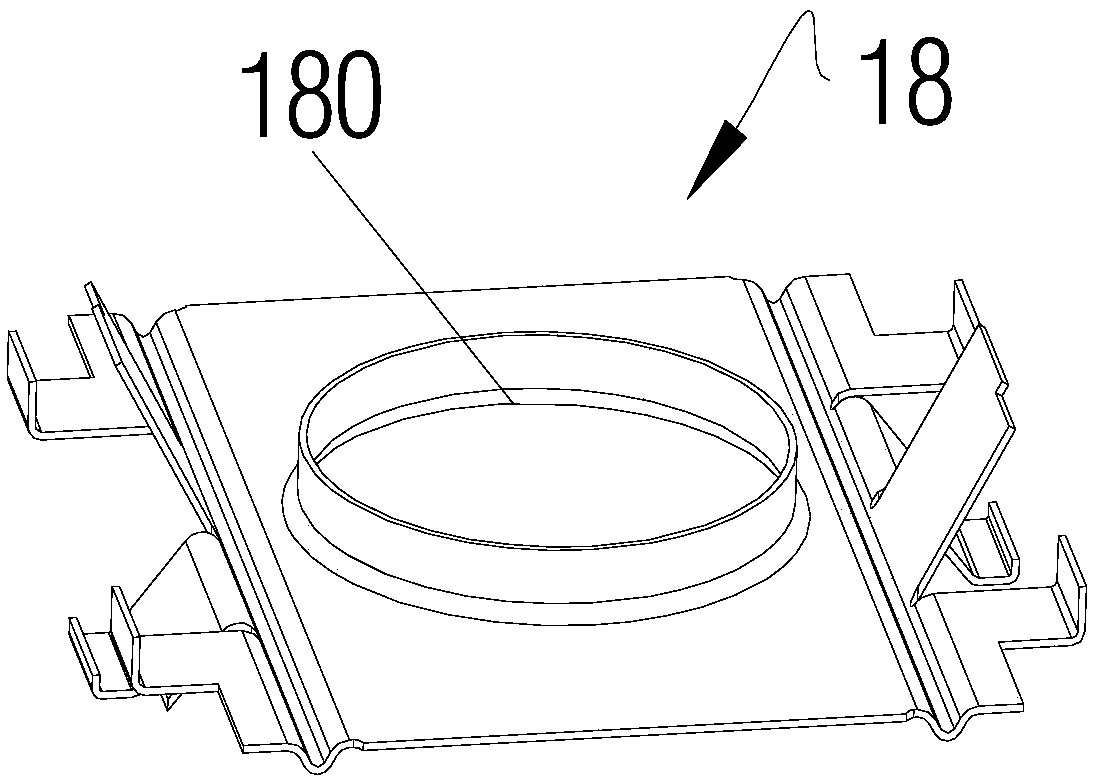

[0036] In order to facilitate the understanding of the cooperation relationship between the magnetron cooling element and other parts, a typical related structure of the black ball assembly 16 in the magnetron is firstly introduced here for the convenience of subsequent description. refer to figure 2 As shown, the interior of the anode cylinder 161 in the black ball assembly 16 is a resonant cavity, and electrons complete energy conversion in this space. Therefore, the heat in the magnetron is mainly generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com