High-power synchronous machine variable-frequency speed regulation system for finishing rolling unit

A technology of frequency conversion speed regulation and finishing rolling mill, which is applied in the field of frequency conversion control and can solve problems such as high energy consumption, weak operation performance, and high-order harmonic pollution to the power grid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with specific embodiments.

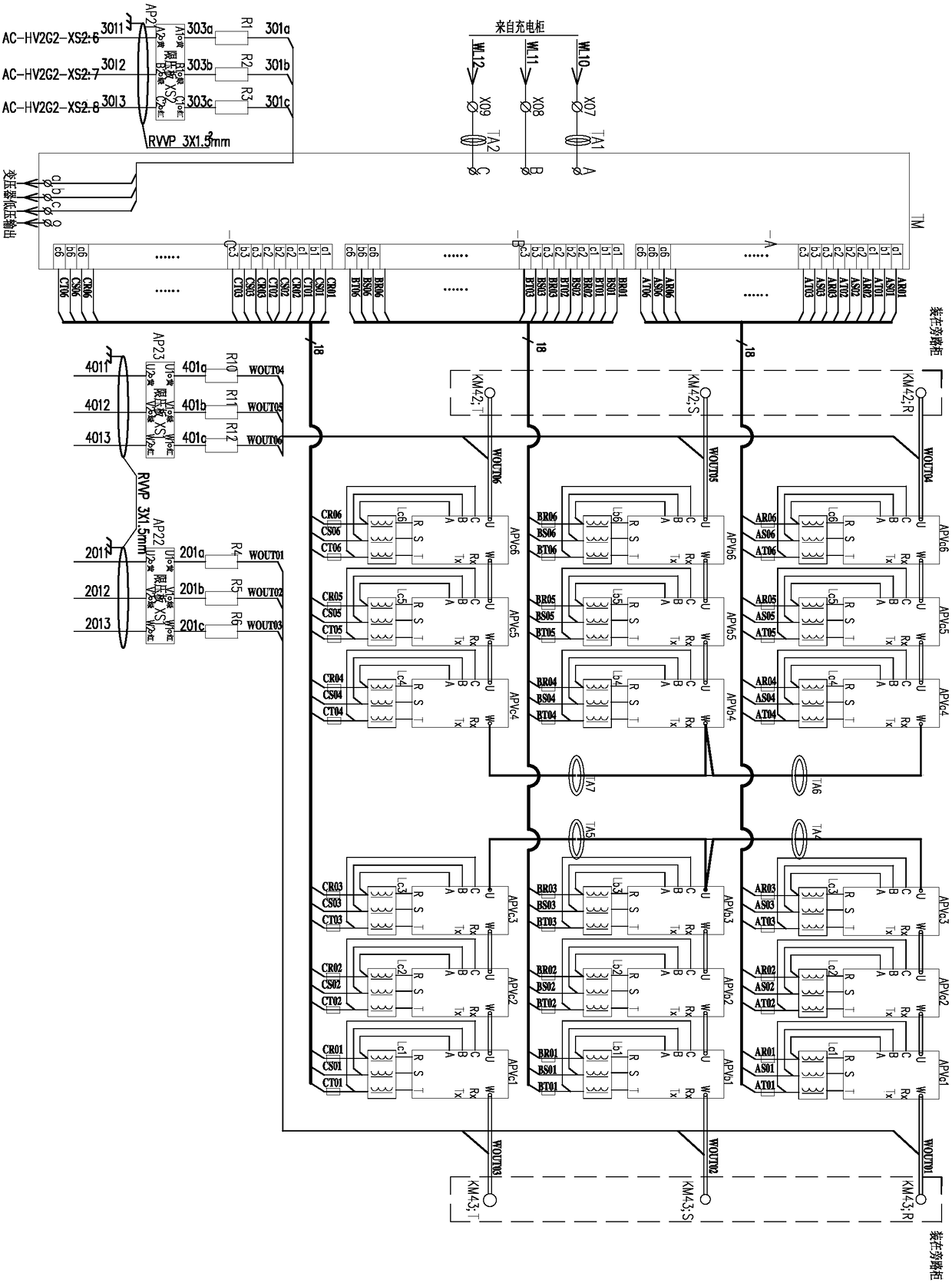

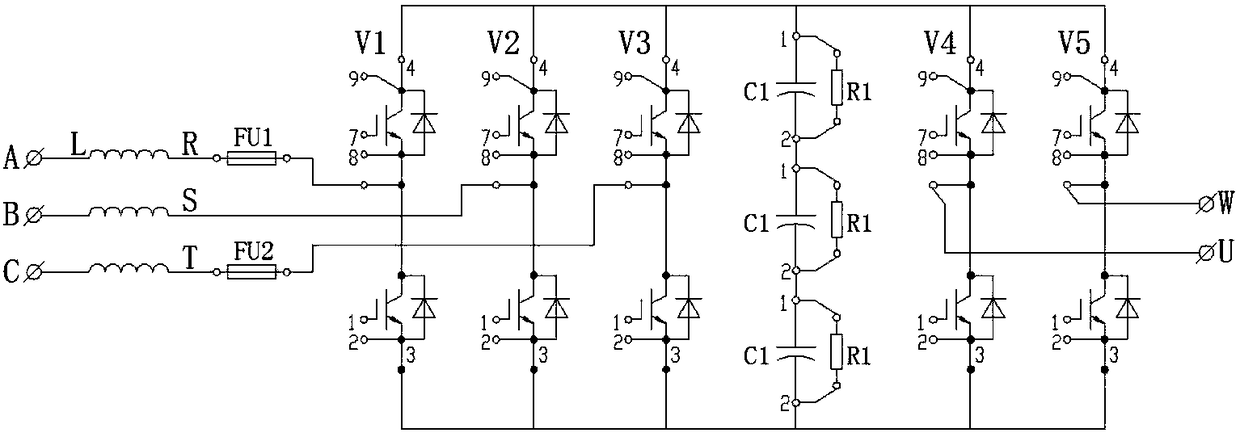

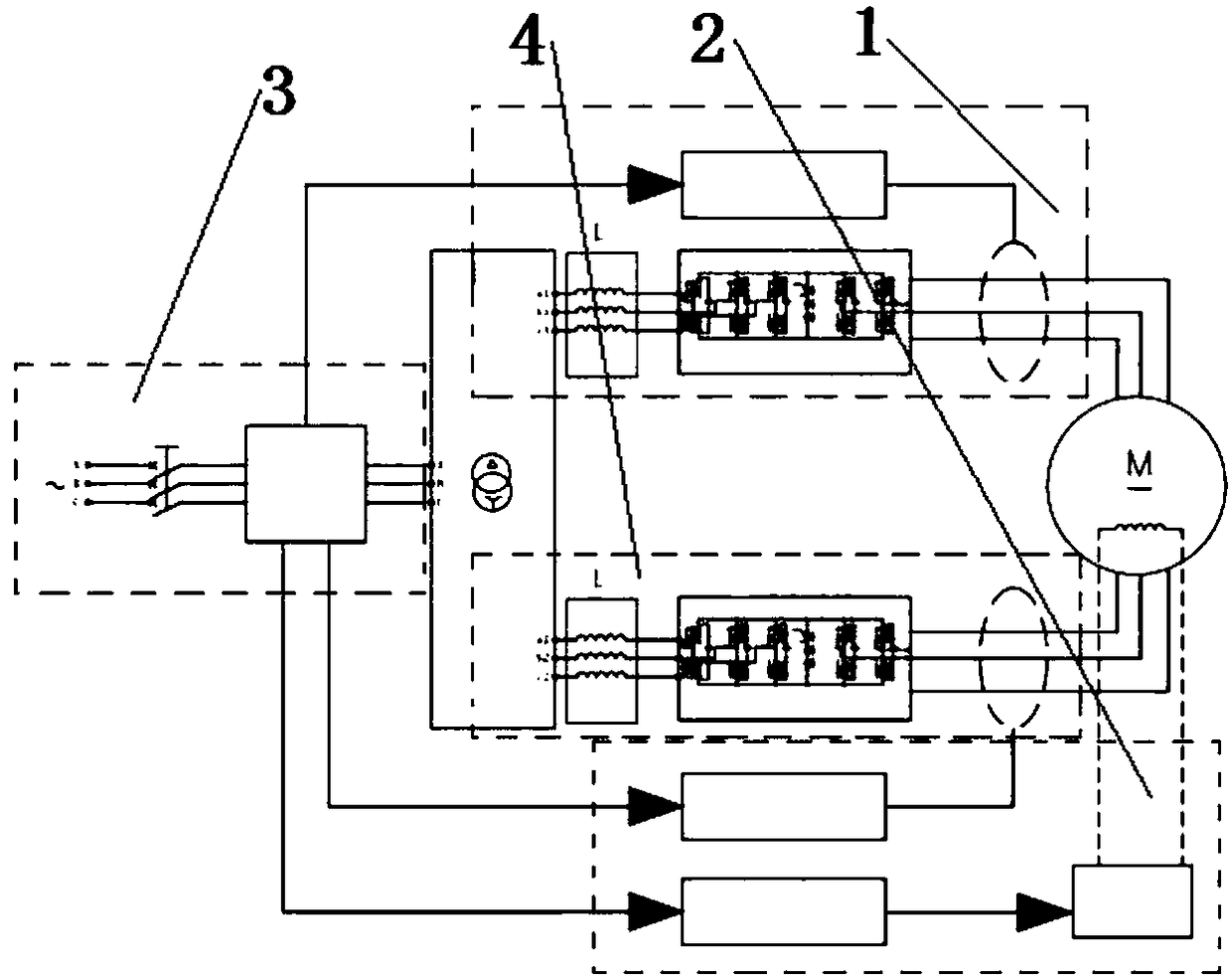

[0027] Such as figure 1 As shown, a high-power synchronous machine variable frequency speed regulation system for a finishing mill includes: a frequency converter system 1, a variable frequency speed regulation system 2, a control system 3, and an energy feedback system 4. The connection is not limited to the existing connection method. The IGBT device is arranged at the end of the circuit in series with the inverter system 1 and the energy feedback system 4 respectively; the inverter system 1, the variable frequency speed regulation system 2 and the energy feedback system 4 are respectively connected in series In series with the control system 3, the frequency conversion speed regulation system 2 includes a controller, a frequency converter, a power unit, and a dual-winding motor. The frequency conversion speed regulation system 2 includes a VFD, an excitation system, a synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com