Rotary iron chain scraper type solid-liquid separation excrement-scraping device and method

A solid-liquid separation and scraper-type technology, which is applied in the field of livestock and poultry breeding, can solve the problem of increasing the breeding, survival and growth of viruses, germs and parasites, increasing the labor intensity of manual cleaning of feces, affecting health, damaging environmental sanitation and air quality, etc. problems, achieve the effect of reducing pollution surface and storage time, reducing construction and equipment costs, and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

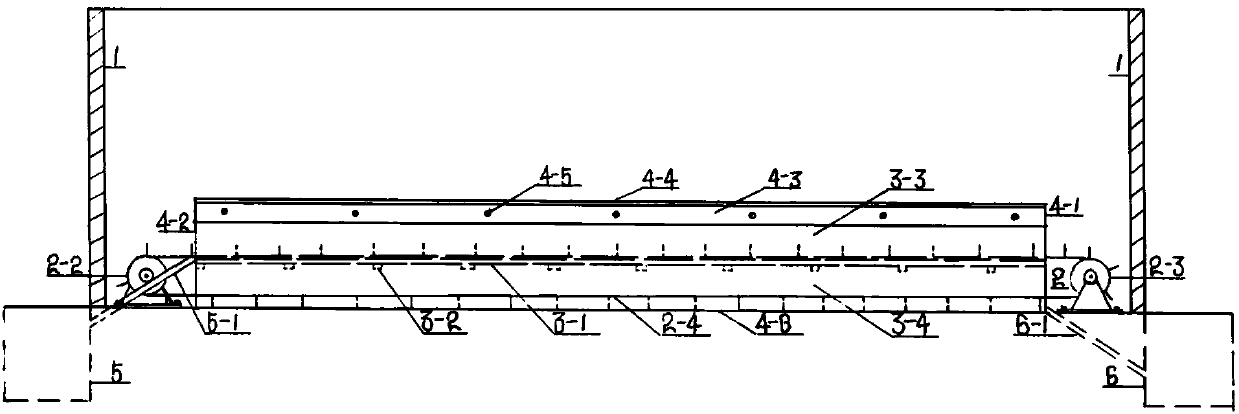

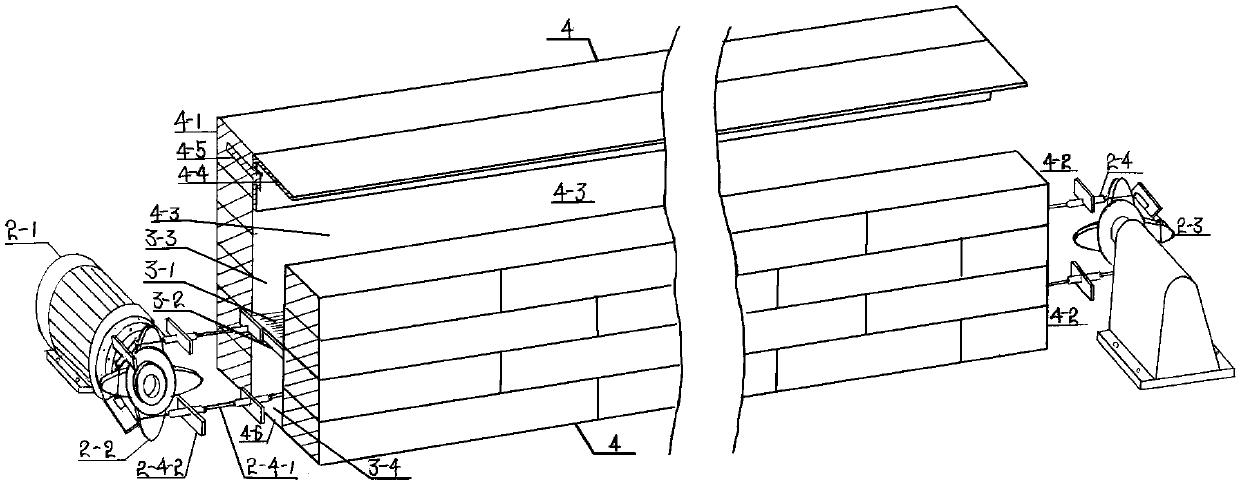

[0032] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, this embodiment includes pen shed 1, and it also includes iron chain scraper scraping device 2, solid-liquid separation device 3, high and low side manure collecting ditch device 4, septic collecting tank 5 and liquid collecting tank 6, height The side manure collecting ditch device 4 is installed below the ground surface in the middle of the pen 1, and the high and low side manure collecting ditch device 4 longitudinally runs through all pens of the whole pen house 1 to the ditch of the manure collecting tank 5 and the liquid collecting tank 6 outside the house , the solid-liquid separation device 3 is installed in the high and low side manure collecting ditch device 4 and is flush with the left and right ends of the high and low side manure collecting ditch device 4, and the iron chain scraper scraping device 2 is installed in the high and low side manure collecting ditch device 4...

specific Embodiment approach 2

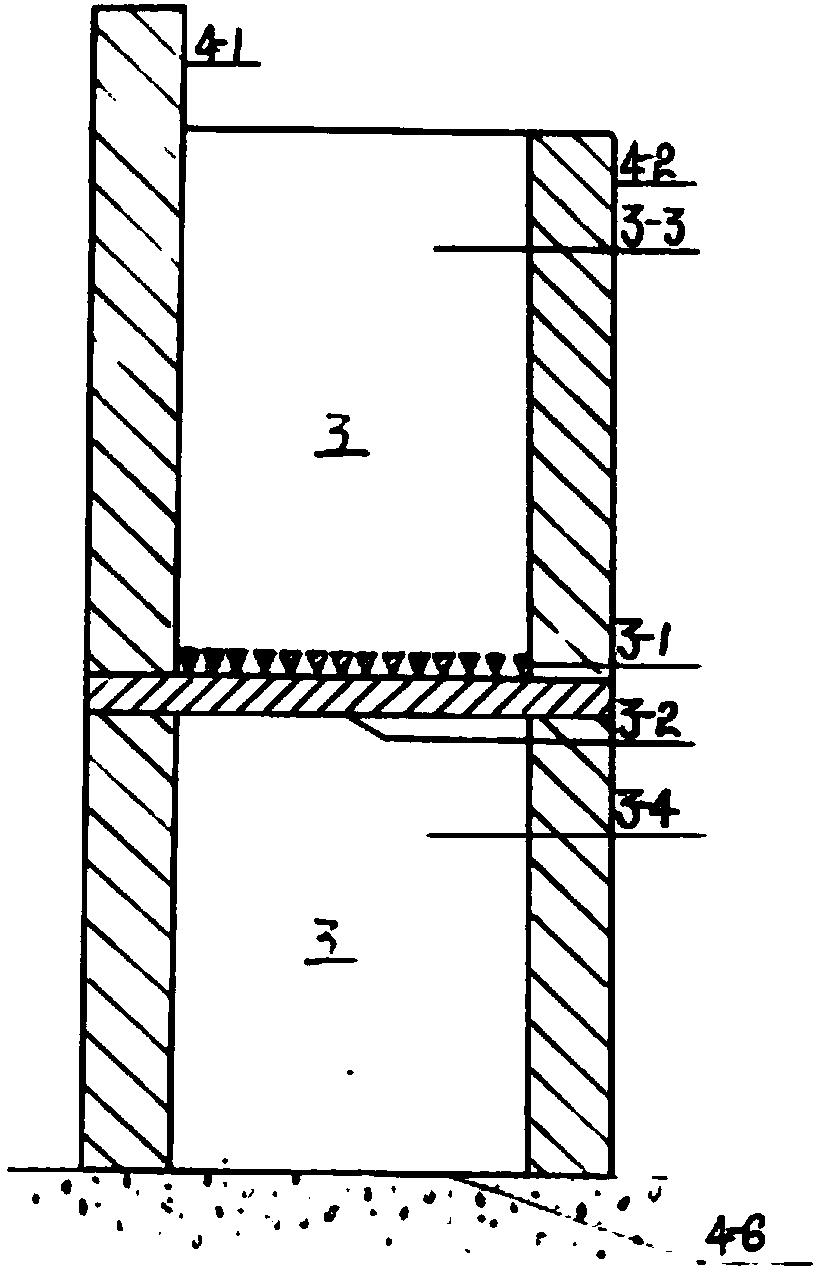

[0033] Specific implementation mode two: combination Figure 1 to Figure 4Illustrate this embodiment, the solid-liquid separation device 3 of this embodiment comprises flat filter bottom 3-1, excrement and liquid leakage tank 3-3, liquid collection tank 3-4 and a plurality of filter bottom joists 3-2; The filter bottom joists 3-2 are equidistantly installed at the position lower than the middle of the low side wall 4-2 in the depth direction of the high and low side manure collection ditch device 4, and the two ends of the filter bottom joists 3-2 are respectively embedded in the high and low side manure collection In the wall of the ditch device 4, the flat filter bottom 3-1 is continuously tiled above the filter bottom joist 3-2, and the flat filter bottom 3-1 and the filter bottom joist 3-2 connect the high and low sides of the excrement collection ditch device 4. The feces collection ditch is divided into upper and lower parts, the upper part of the flat plate filter botto...

specific Embodiment approach 3

[0038] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, multiple rows of long slats 3-1-3 are provided on the flat filter bottom 3-1 of this embodiment, and a slat horizontal partition is provided between two adjacent rows of long slats 3-1-3 Board 3-1-2, each row of strip slats 3-1-3 are equidistantly spaced by a plurality of slat partitions 3-1-1. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0039] The strip slit 3-1-3 of the present embodiment allows the liquid substance to seep from the slit and not be blocked.

[0040] The slat partition plate 3-1-1 of this embodiment divides the flat filter bottom into several slats.

[0041] The slatted transverse partition 3-1-2 of this embodiment is located between the two rows of slats 3-1-3 and the slatted spacer 3-1-1 and is perpendicular to the height of the slatted spacer. The role of the separator is to increase the strength of the flat fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com