Tubular type centrifuge

A tube centrifuge and feeding tube technology, applied in centrifuges and other directions, can solve the problems of labor and time waste, affecting product quality, secondary pollution, etc., to avoid damage, achieve automatic cleaning, and improve work productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

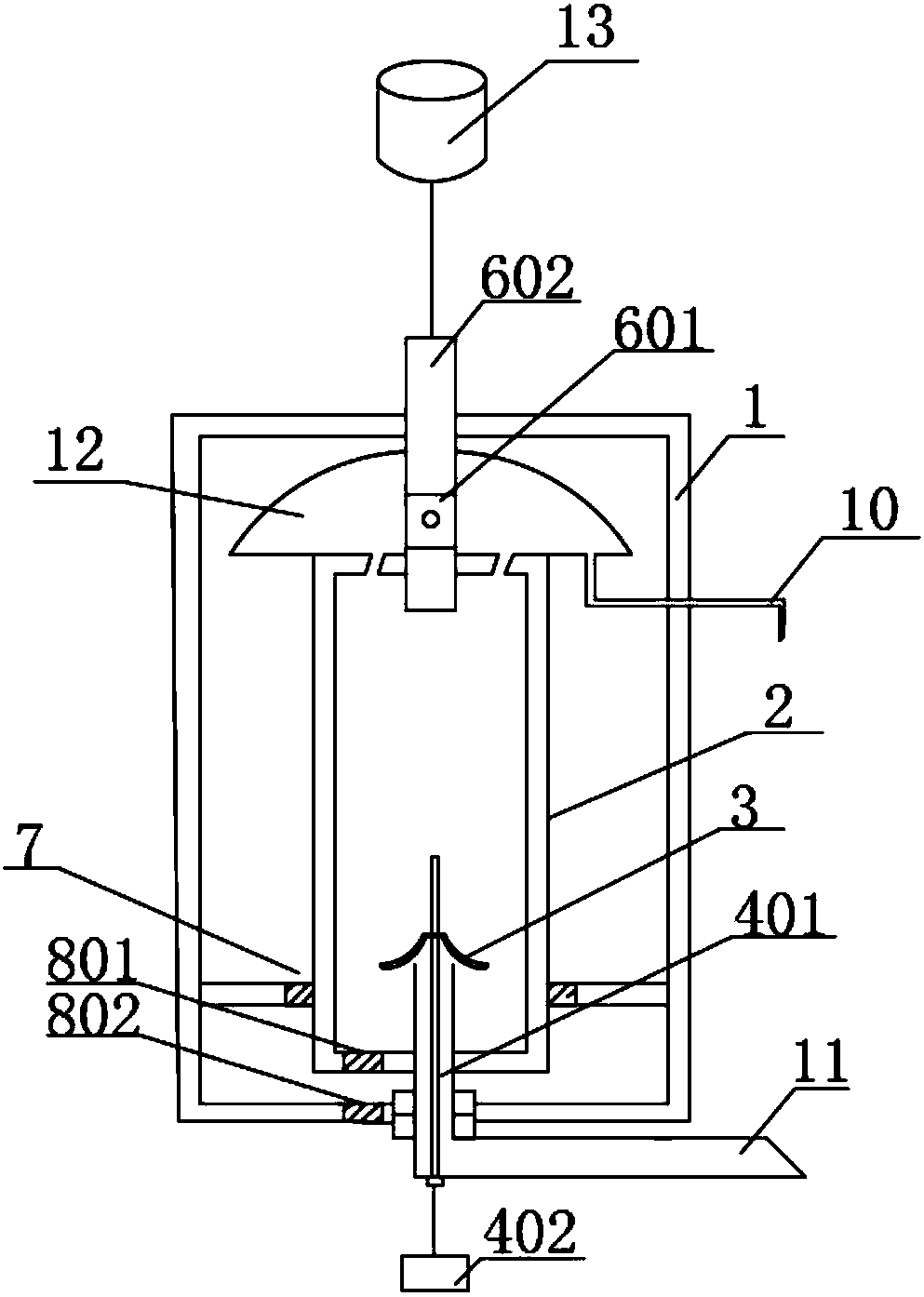

[0026] Such as figure 1 As shown, the liquid medicine to be separated and the clarifying agent are delivered to the inside of the drum 2 through the feed pipe 11; the drive shaft 602 is driven by the motor 13 to move, and the drum 2 is driven by the high-speed Form a strong centrifugal force field, use centrifugal force instead of gravity and cooperate with the flocculation of clarifier to quickly separate the clear liquid and solid particles in the liquid medicine, and the clear liquid flows out from the through hole at the upper end of the drum 2 and is collected by the liquid collecting plate 12. And flow out through the liquid outlet pipe 10; the solid residue is deposited at the bottom of the drum 2.

[0027] After the tubular centrifuge has been working for a period of time, instead of delivering liquid medicine and clarifying agent to the drum 2, the cleaning liquid or water is delivered to the inside of the drum 2 through the feed pipe 11; the side of the control nozzl...

Embodiment 2

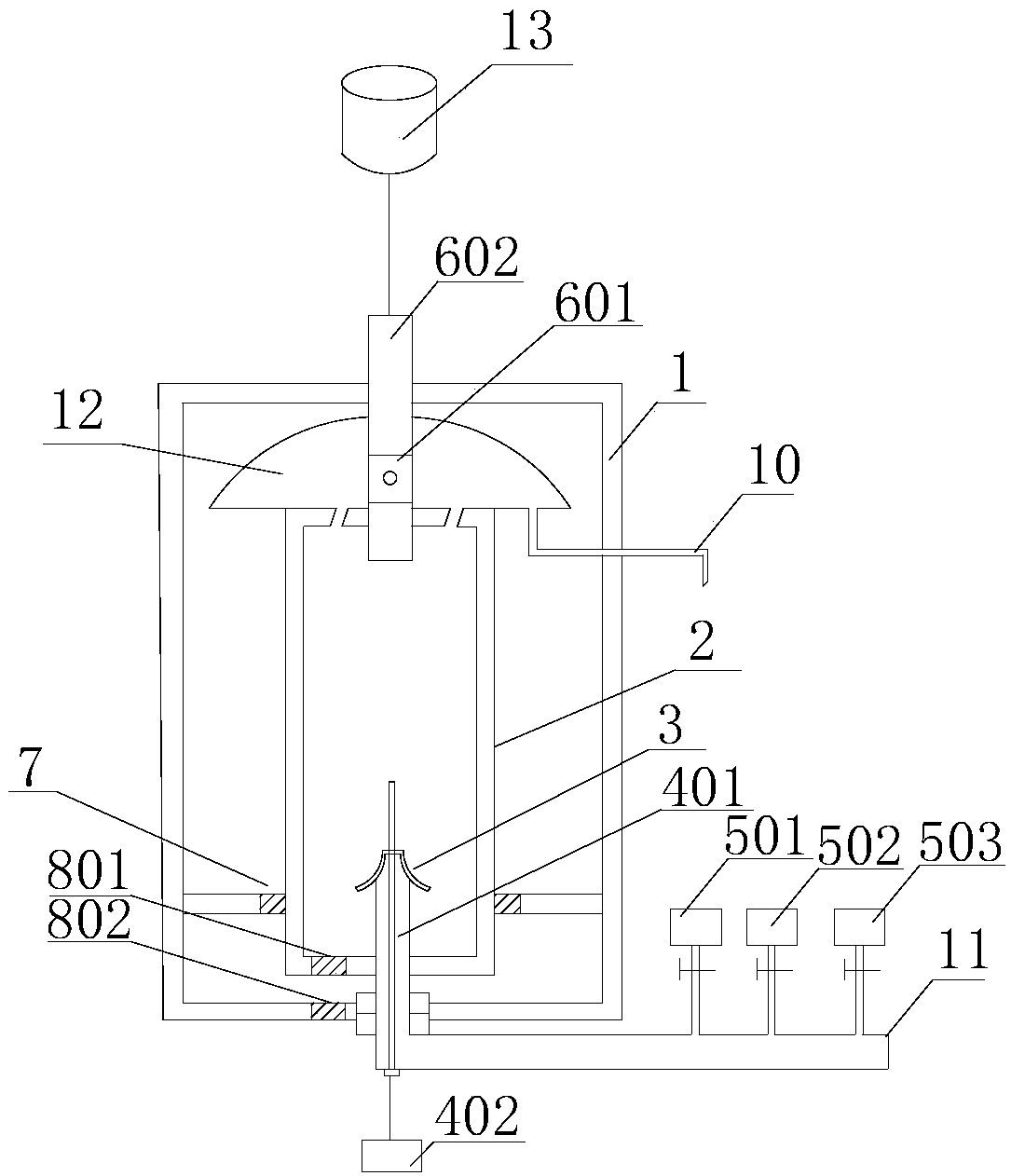

[0029] Such as figure 2 As shown, the feeding pipe 11 is connected with the liquid medicine liquid storage tank 501, the clarifying agent liquid storage tank 502, and the third liquid storage tank 503 for storing cleaning liquid or water; the liquid medicine liquid storage tank 501, the liquid medicine liquid storage tank 501, The liquid medicine and clarifier in the clarifier liquid storage tank 502 are delivered to the inside of the drum 2 through the feed pipe 11; the drive shaft 602 is driven by the motor 13 to move, and the drum 2 is driven by the drive shaft 602 and the coupling 601, A strong centrifugal force field is formed through high speed, and centrifugal force is used instead of gravity and combined with the flocculation of clarifier, so that the clear liquid and solid particles in the liquid medicine are quickly separated, and the clear liquid flows out from the through hole at the upper end of the drum 2 and is collected by the liquid collection plate. 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com