Micro-pore atomizer polishing machine and polishing method

A microporous atomization and polishing machine technology, applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of reducing printing accuracy, product damage, difficult to obtain polishing treatment, etc., and achieve the effect of improving the surface effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

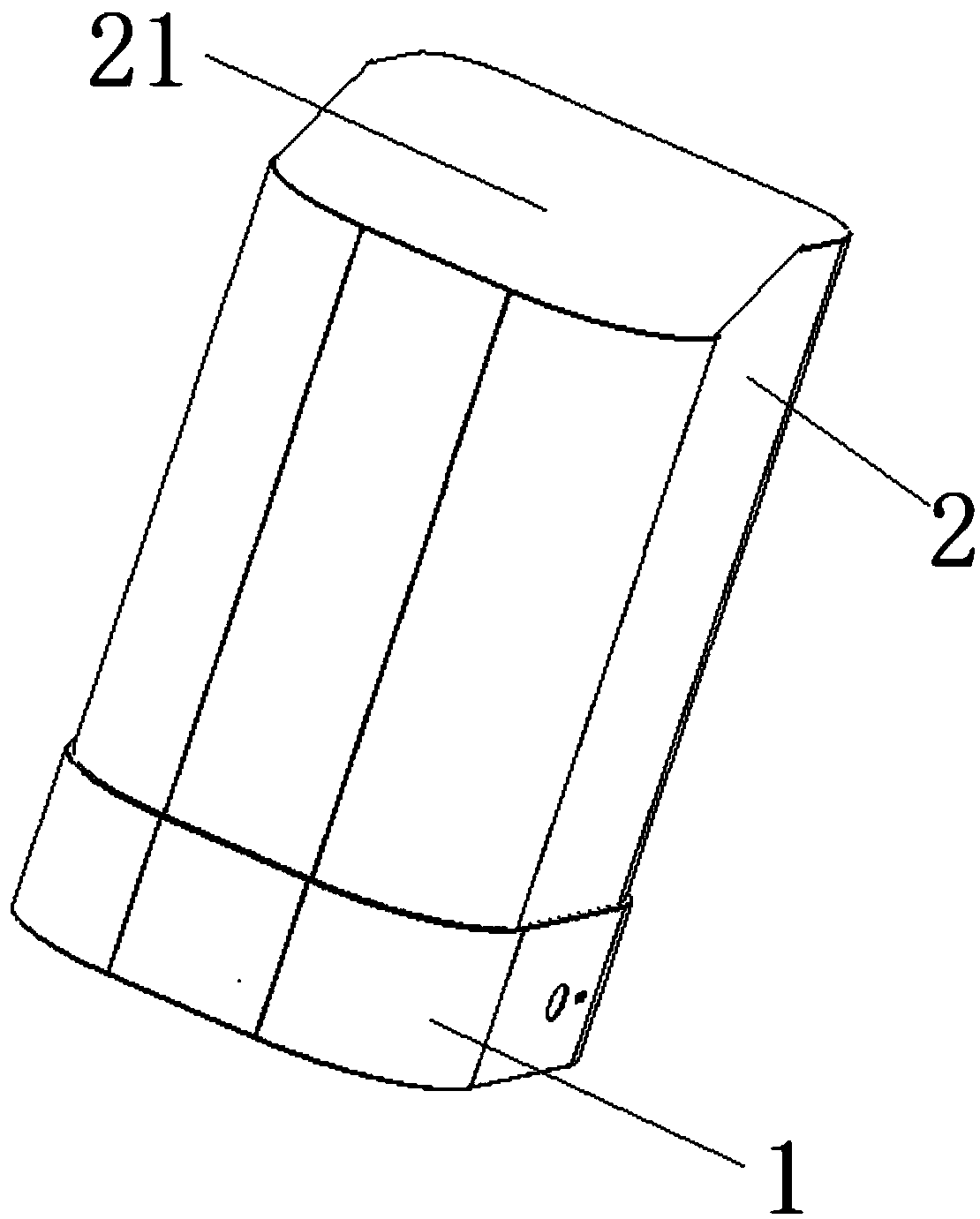

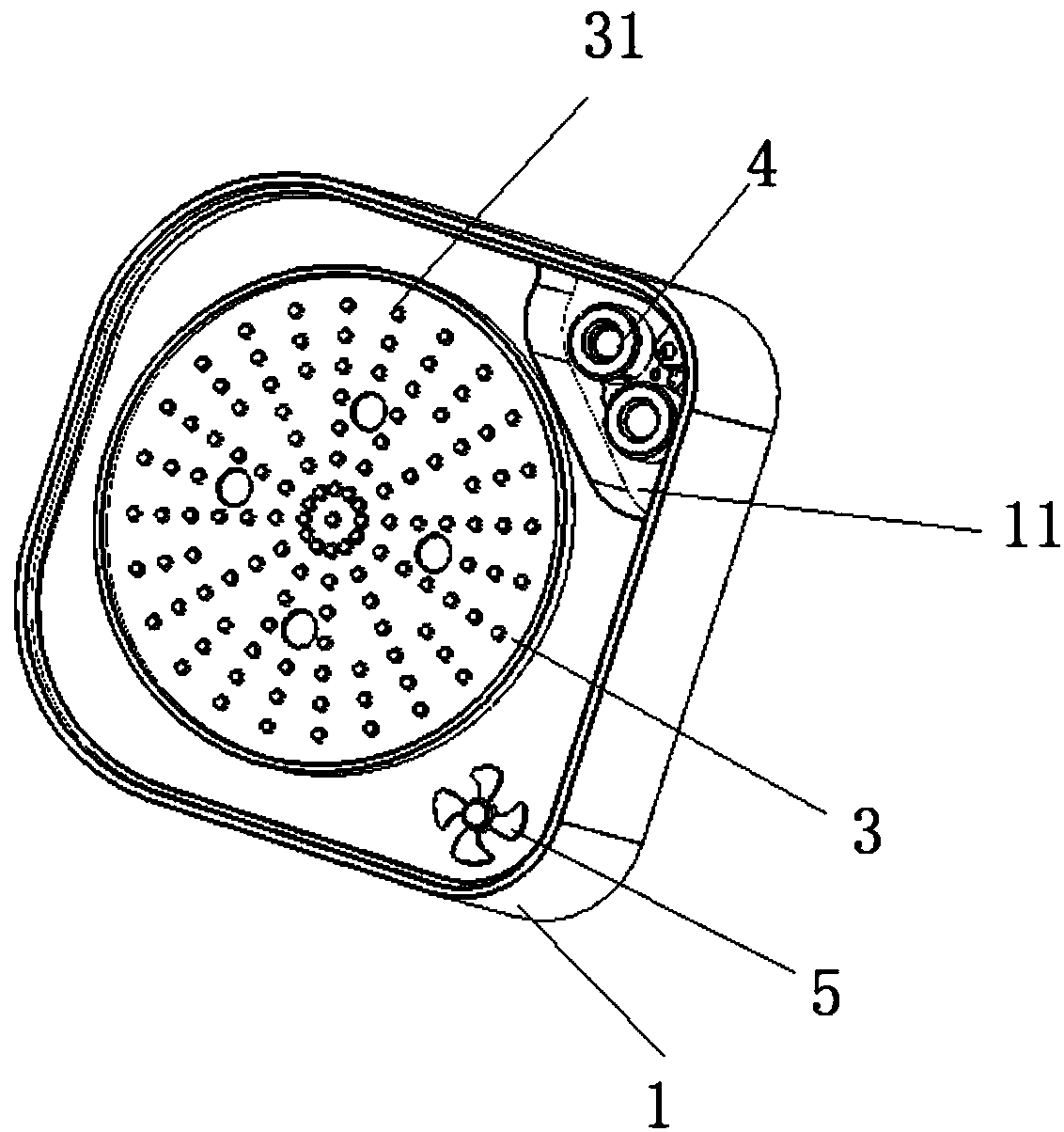

[0046] This embodiment provides a microporous atomizer polishing machine, such as figure 1 shown, including:

[0047] The seat body 1, the cross section is preferably a rounded rectangle, the interior of the seat body 1 is an accommodating cavity, the side wall of the seat body 1 is higher than the top of the seat body 1, and at least one corner of the top of the seat body 1 is provided with The sunken sump 11, the top surface of the seat body 1 is inclined towards the direction of the sump 11, so that the alcohol can flow smoothly into the sump 11, (as figure 2 As shown, the sump 11 is on the rear left side, figure 2 Left is front, right is rear);

[0048] The cover body 2 is preferably made of a transparent material, and the cover is installed on the top of the seat body 1;

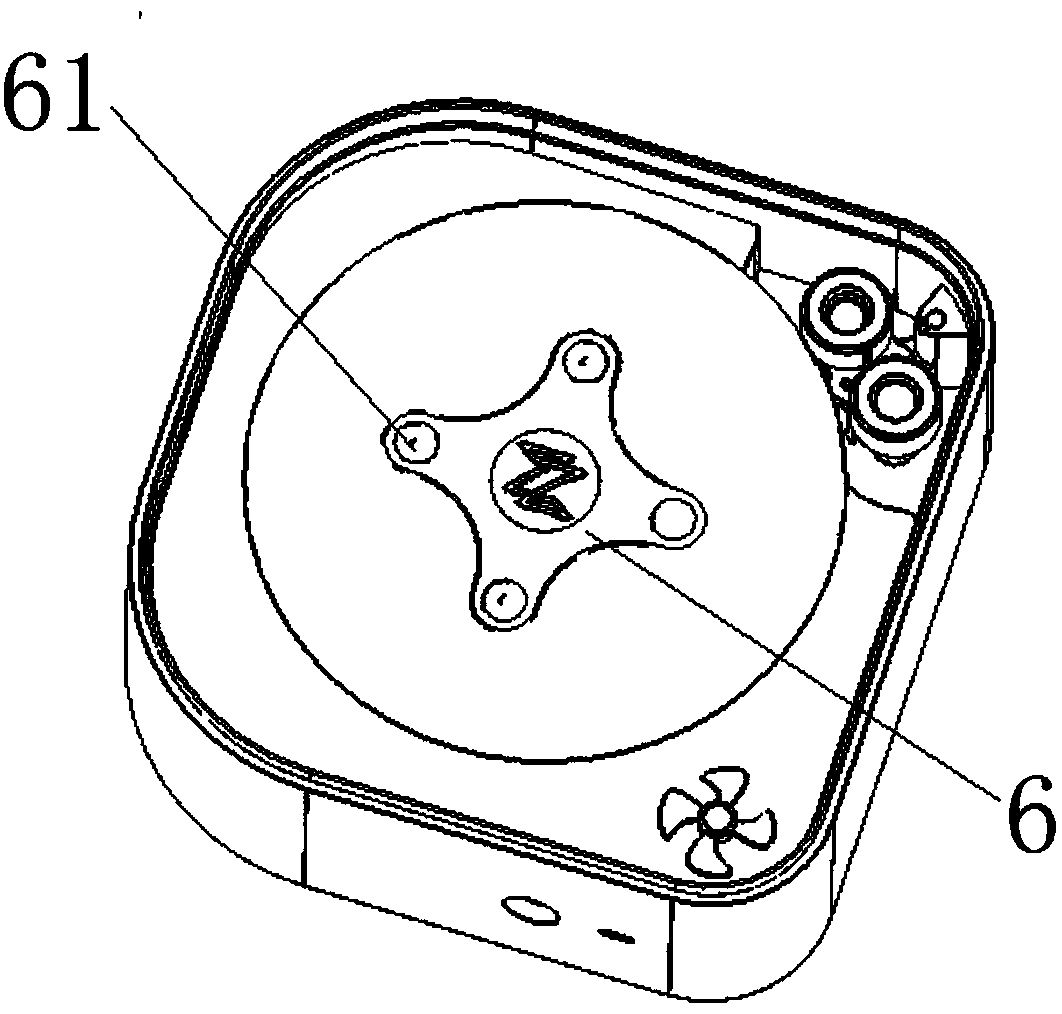

[0049] The support seat 6 is arranged in the middle position of the top of the seat body 1, and is in the shape of a cross, and the top surface of the support seat 6 is provided with four permanent...

Embodiment 2

[0060] This embodiment provides a microporous atomization polishing method for 3D printed objects, using a fan 5, including the following steps:

[0061] S1: place the 3D printed object on the storage tray 3;

[0062] S2: start the atomizer 4, and start the fan 5 with a delay of 6-10s;

[0063] S3: Drive the 3D printed object to rotate, the rotation speed is 2-3 revolutions / min, and the fan 5 stops for 1-2 minutes every time it rotates for 2-5 minutes;

[0064] S4: After the surface of the 3D printed object is smooth, stop the atomizer 4, and the fan 5 will be turned off after a delay of 10-30s;

[0065] S5: Clean the alcohol on the surface of the 3D printed object.

[0066] In the microporous atomization and polishing method of the present embodiment, the fan 5 stops for 1-2 minutes every time it rotates for 2-5 minutes, so that the atomized alcohol in the air can be blown up by the fan 5 after falling to a certain height. , forming a turbulent flow, so that the downward f...

Embodiment 3

[0068] This embodiment provides a microporous atomization polishing method for 3D printed objects, using two fans 5, including the following steps:

[0069] S1: place the 3D printed object on the storage tray 3;

[0070] S2: start the atomizer 4, and start the fan 5 with a delay of 6-10s;

[0071] S3: Drive the 3D printed object to rotate at a rotation speed of 2-3 revolutions / min. After the two fans 5 run together for 2-5 minutes each time, they alternately run for 1-2 minutes (only one fan 5 runs alternately);

[0072] S4: After the surface of the 3D printed object is smooth, stop the atomizer 4, and the fan 5 will be turned off after a delay of 10-30s;

[0073] S5: Clean the alcohol on the surface of the 3D printed object.

[0074] In the microporous atomization polishing method of this embodiment, the two fans 5 run together for 2-5 minutes at a time, and then run alternately for 1-2 minutes, so that the atomized alcohol in the air directly forms a turbulent flow, making...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com