Production process for treating wooden furniture by using water-based paint

A wooden furniture and production process technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of transparency, color depth, anti-cracking and deformation of antique effect, etc., to prevent furniture surface Cracking, easy to absorb, good effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A production process for treating wooden furniture with water-based paint, specifically comprising the following steps:

[0045] (1) Bleaching treatment: receive the polished product, and then rub the bleaching paint on the product to make the color of the product basically the same after bleaching; where the wood color is relatively dark or uneven, it must be bleached several times to make the whole set The color of the product after bleaching is basically the same. If there is any sand wear, the product should be adjusted in time before it is repaired, so as to avoid damage and deformation caused by moisture;

[0046] (2) Health care treatment: Put the bleached product into the health care room. The temperature of the health care room is 20-30°C, the humidity is 20-40%, and the health care time is 24-72h. out of the warehouse again;

[0047](3) The first grinding treatment: use 180# sandpaper, and use a sandpaper machine to polish the surface of the product. It needs...

Embodiment 2

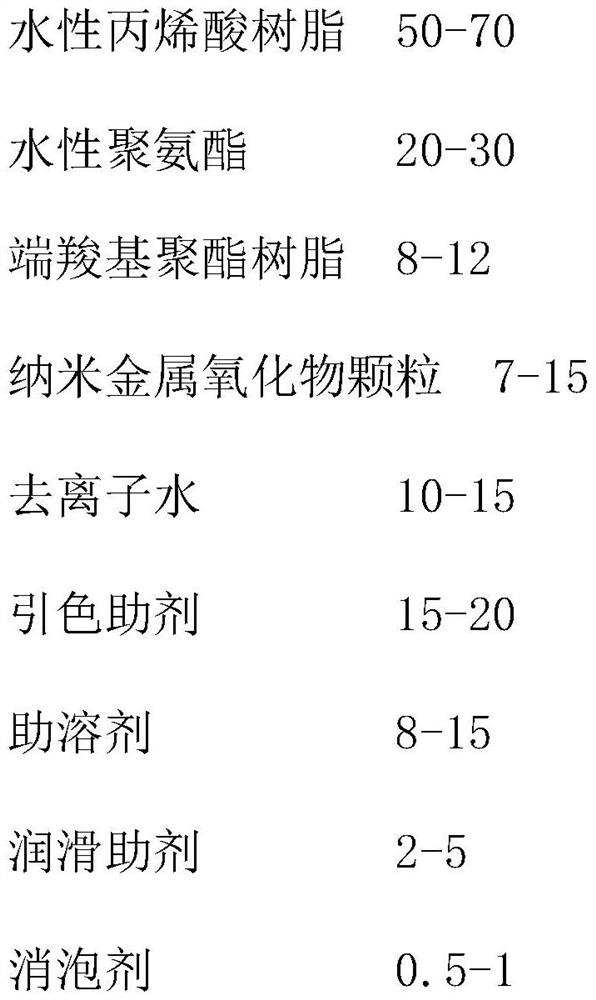

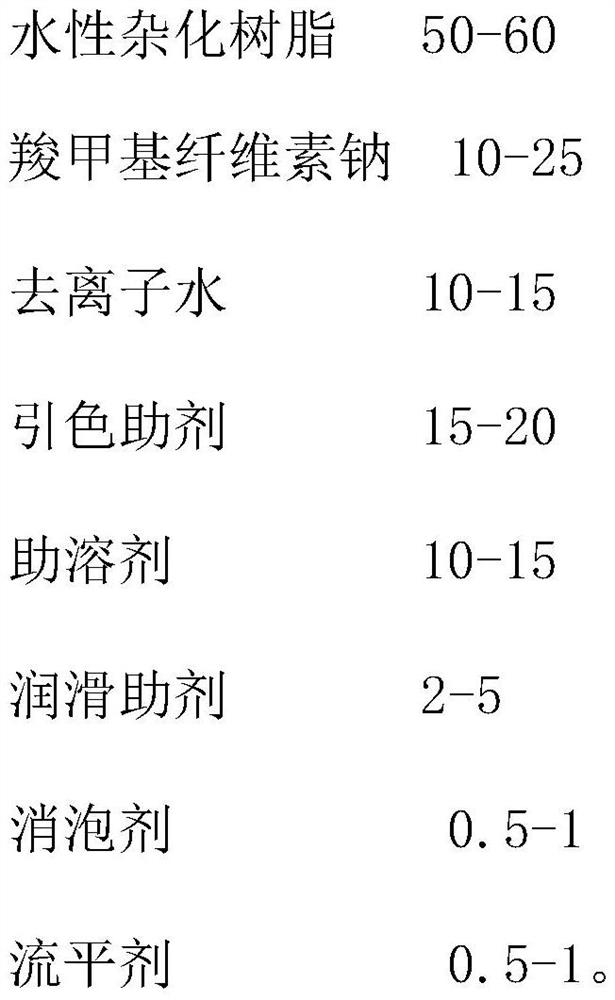

[0058] The main difference between this embodiment and Example 1 is that in step (4), the ratio of the water-based color attractant A to the water-based color attractant B is 6:1, wherein the raw materials contained in the color attractant A and the parts by weight of the raw materials are: Water-based acrylic resin 70, water-based polyurethane 20, carboxyl-terminated polyester resin 10, nano-metal oxide particles 9, deionized water 10, color-attracting aid 20, co-solvent 8, lubricating aid 5, defoamer 0.5, leveling Agent 1; the raw materials and raw material parts by weight contained in color attracting agent B are: water-based hybrid resin 60, sodium carboxymethyl cellulose 10, deionized water 10, color attracting aid 20, cosolvent 10, lubricating aid 2 , defoamer 1, leveling agent 0.5;

[0059] In the step (9), the ratio of the two-component varnish finish paint to the water-based curing agent is 7:1:1, wherein the raw materials and the parts by weight of the raw materials ...

Embodiment 3

[0061] The main difference between this implementation and Example 2 is that in step (4), the ratio of the water-based A color-binding agent and the water-based B color-binding agent is 5.5:1;

[0062] In the step (8), the raw materials and raw materials included in the color coating are: 35 water-based acrylic resins, 10 deionized water, 30 smooth oils, 20 color fixing agents, and 25 cosolvents; the raw materials and raw materials included in the color repair coating The parts by weight are: 15 deionized water, 35 cosolvents, 35 color fixing agents;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com