Ceramic superconducting high-pressure rotary cutting blockage removal device

A high-pressure spinning and superconducting technology, used in packaging, transportation, packaging, containers, etc., can solve the problems of long construction period, high cost, and large amount of modification engineering, achieving high degree of automation, low labor intensity, and good blocking effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

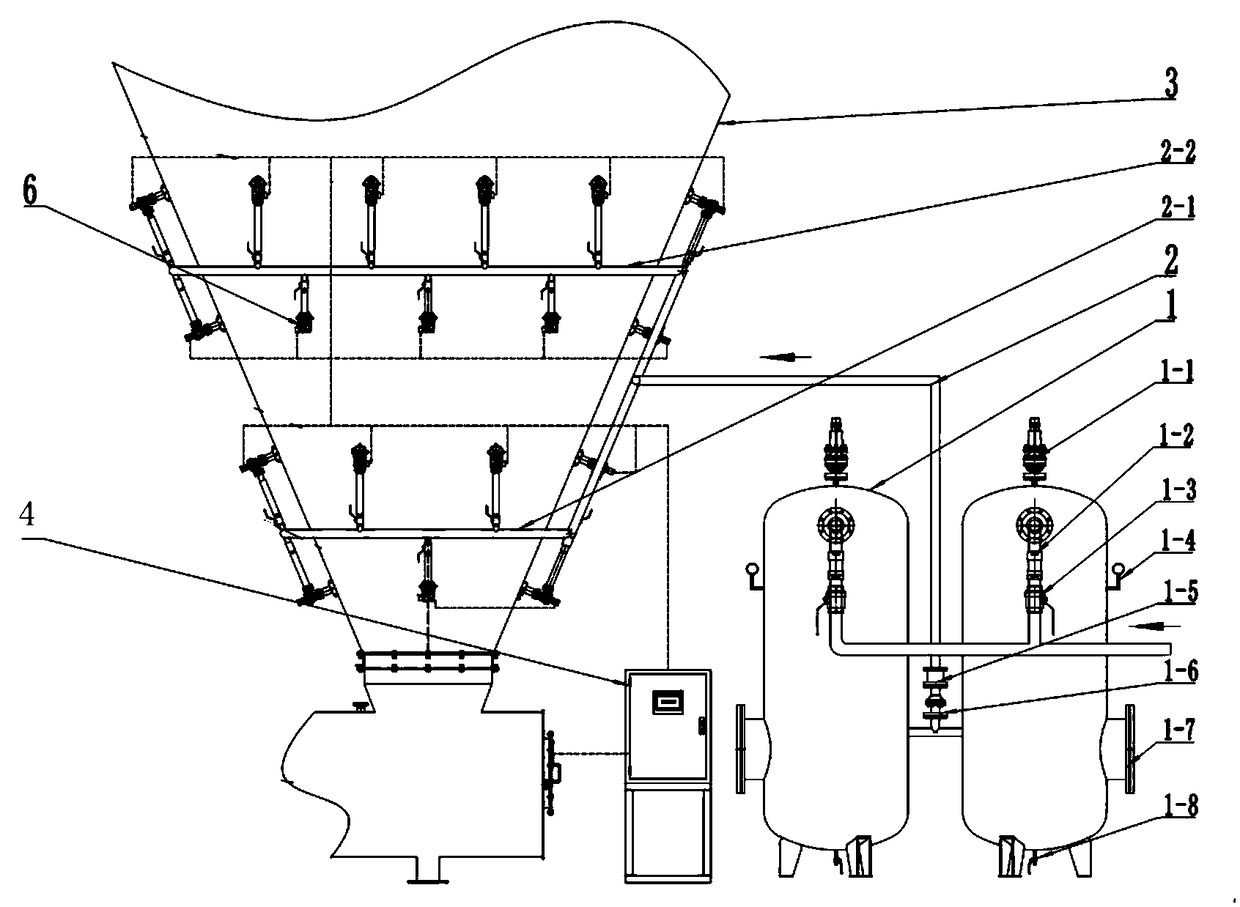

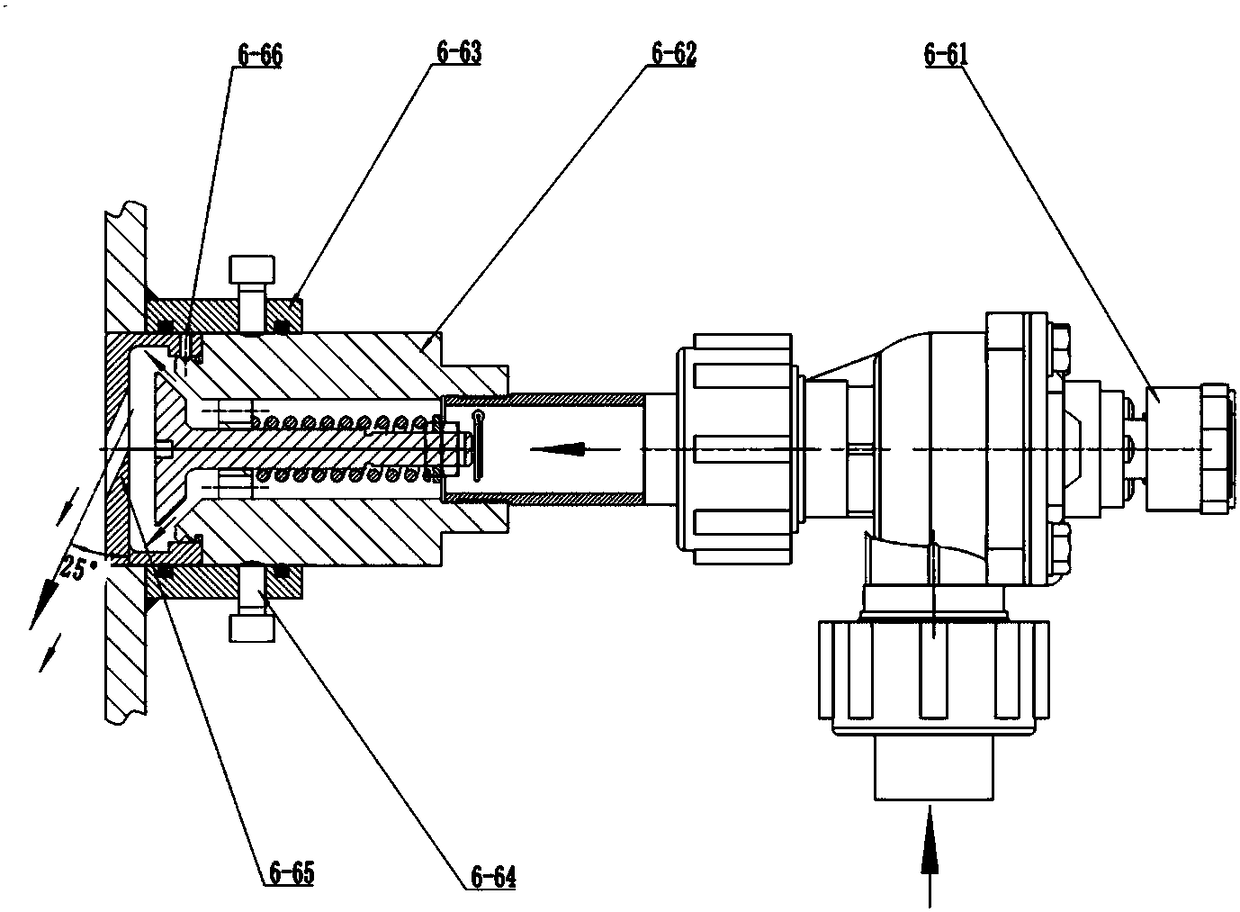

[0020] Such as Figure 1-2 As shown, the ceramic superconducting high-pressure rotary cutting device of the present invention includes: a gas storage tank 1, a gas delivery pipe 2, a PLC control cabinet 4 and several ceramic nozzle groups 6;

[0021] Wherein, the top of the gas storage tank 1 is provided with a safety valve 1-1, and the safety valve 1-1 is connected to one end of the intake check valve 1-2, and the other end of the intake check valve 1-2 is One end is connected to one end of the inlet ball valve 1-3, the other end of the inlet ball valve 1-3 is connected to one end of the air delivery pipe 2, and the air delivery pipe 2 is connected to one end of the air delivery branch pipe 2-1, so The other end of the gas transmission branch pipe 2-1 is respectively connected to the air inlets of several ceramic nozzle groups 6, and several...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com