High-precision gradient loss detection method and device based on ultrasonic sensor

A loss detection, ultrasonic technology, applied in escalators, transportation and packaging, etc., can solve the problems of poor practicability, achieve the effect of avoiding poor practicability, high precision, and promoting detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

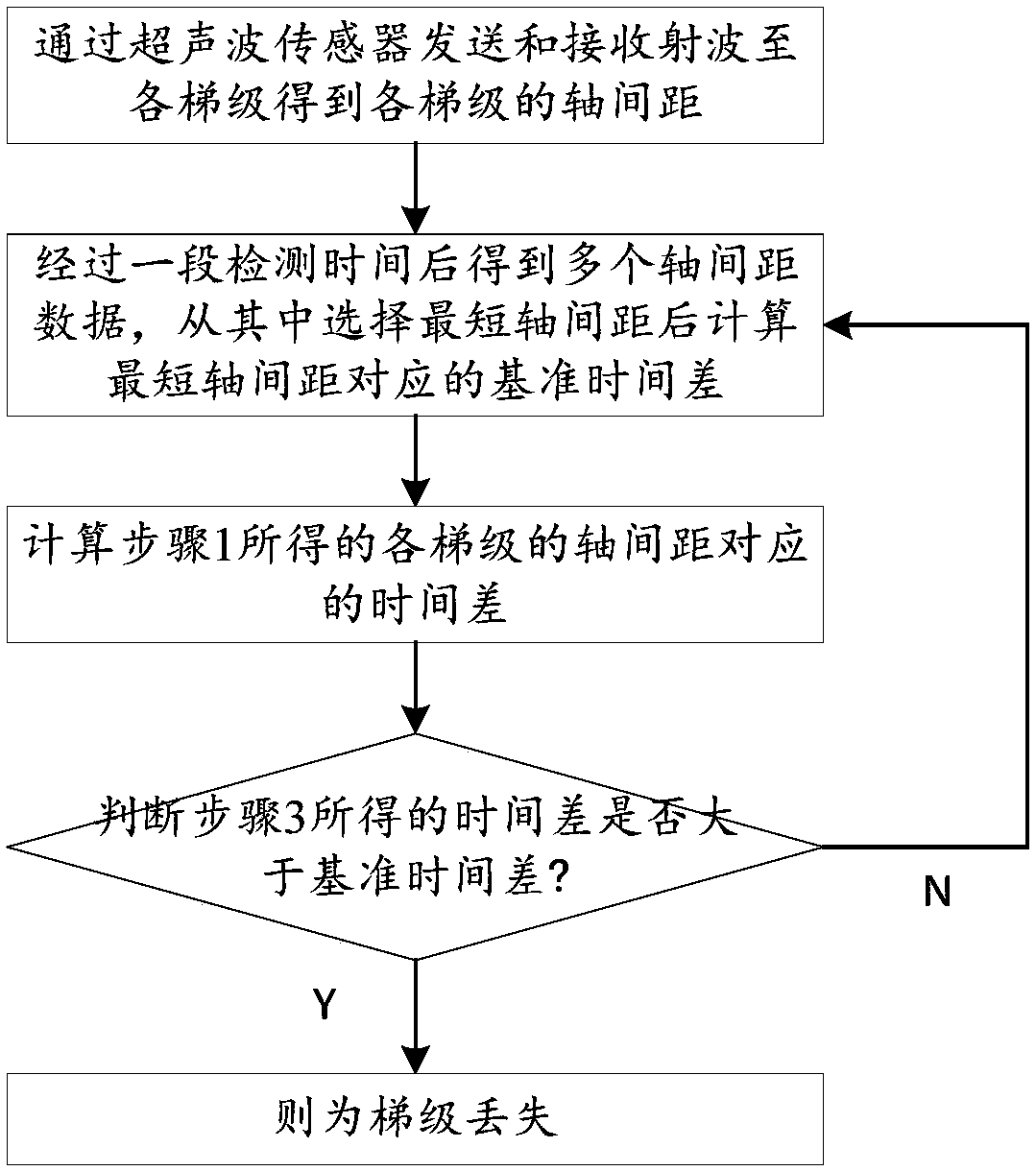

[0037] A high-precision step loss detection method based on ultrasonic sensors includes the following steps:

[0038] Step 1: Use the ultrasonic sensor to send and receive radio waves to each step to obtain the axis distance of each step;

[0039] Step 2: After a period of detection time, multiple axis distance data are obtained, and the shortest axis distance is selected from among them, and the reference time difference corresponding to the shortest axis distance is calculated;

[0040] Step 3: Calculate the time difference corresponding to the axis spacing of each step obtained in Step 1;

[0041] Step 4: Determine whether the time difference obtained in step 3 is greater than the reference time difference, if it is greater than the step loss; if not, skip to step 2.

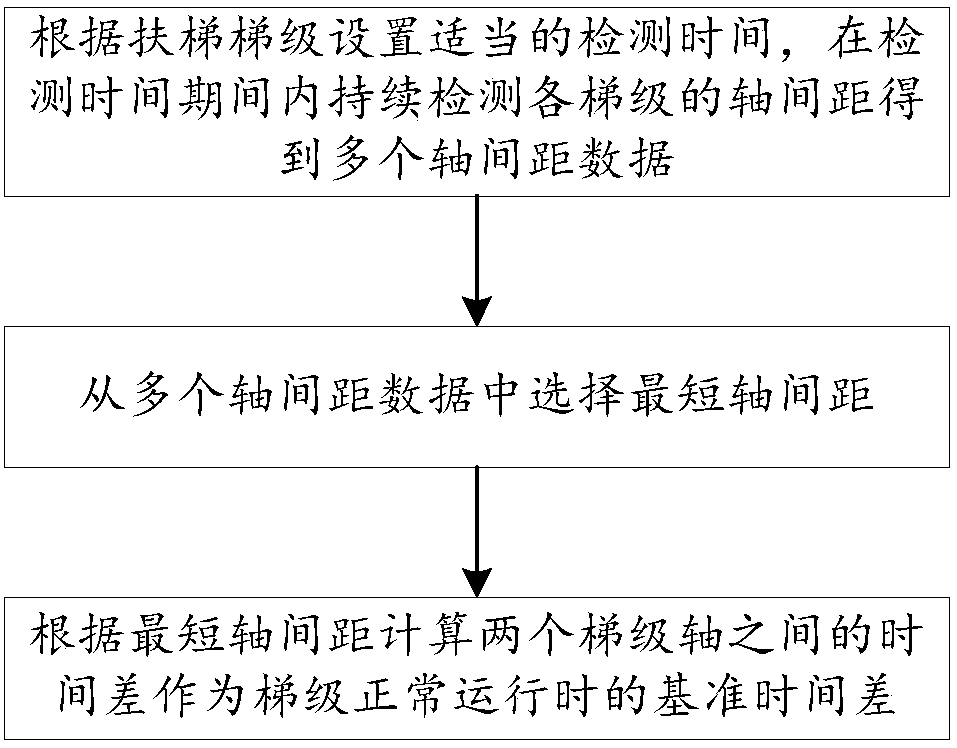

[0042] Step 2 includes the following steps:

[0043] Step 2.1: Set an appropriate detection time according to the escalator step, and continuously detect the axis distance of each step during the detection time to obtai...

Embodiment 2

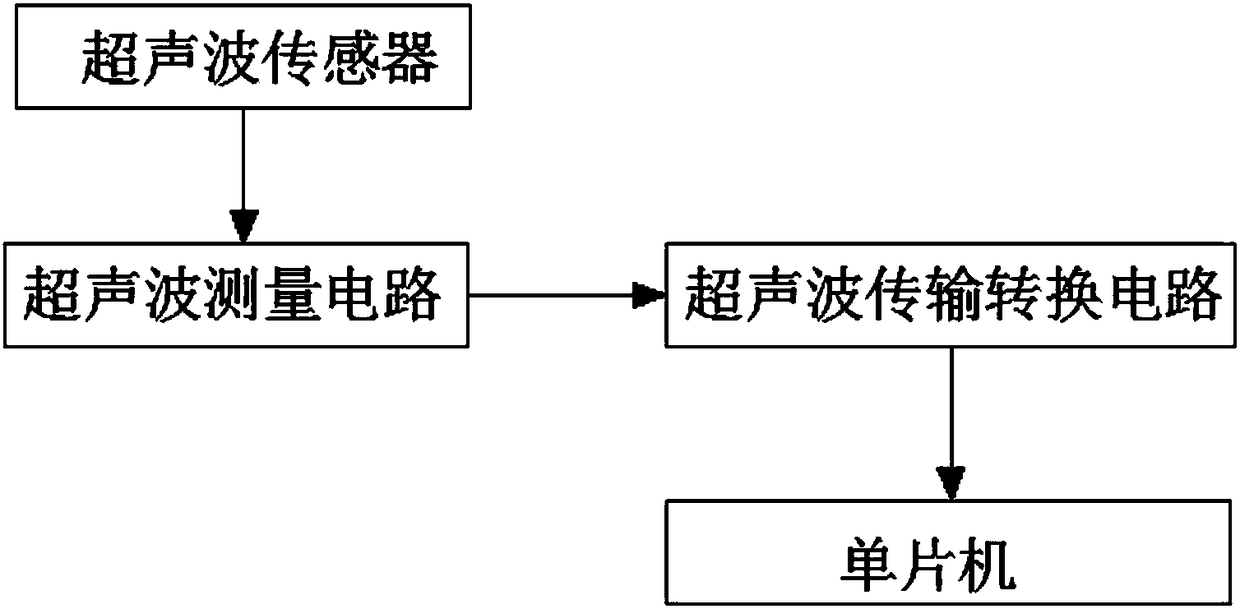

[0056] An ultrasonic sensor-based high-precision step loss detection method and device, including the following steps: first send and receive radio waves through the ultrasonic sensor, the ultrasonic measurement circuit performs waveform signal measurement and processing, and then converts the processed waveform signal through the waveform-serial port After the chip, analog-to-digital conversion unit and signal isolation chip are converted, they are transmitted to the single-chip microcomputer. The single-chip microcomputer calculates the step-axis spacing. After a detection time of 5-10 minutes, the single-chip microcomputer calculates the shortest step-axis spacing during the detection time. Calculate the reference time difference between the corresponding step axis, according to the calculation reference time difference is 1.5s; because each step corresponds to a step axis, if the step is lost, the time difference corresponding to the step axis spacing will be greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com