Fireproof, waterproof and moistureproof outer decoration prefabricated wall enclosure material, and preparation method and application thereof

An envelope material and prefabricated wall technology, applied in the field of materials, can solve the problems of single function and uneven quality, and achieve the effects of simple method, easy process control and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

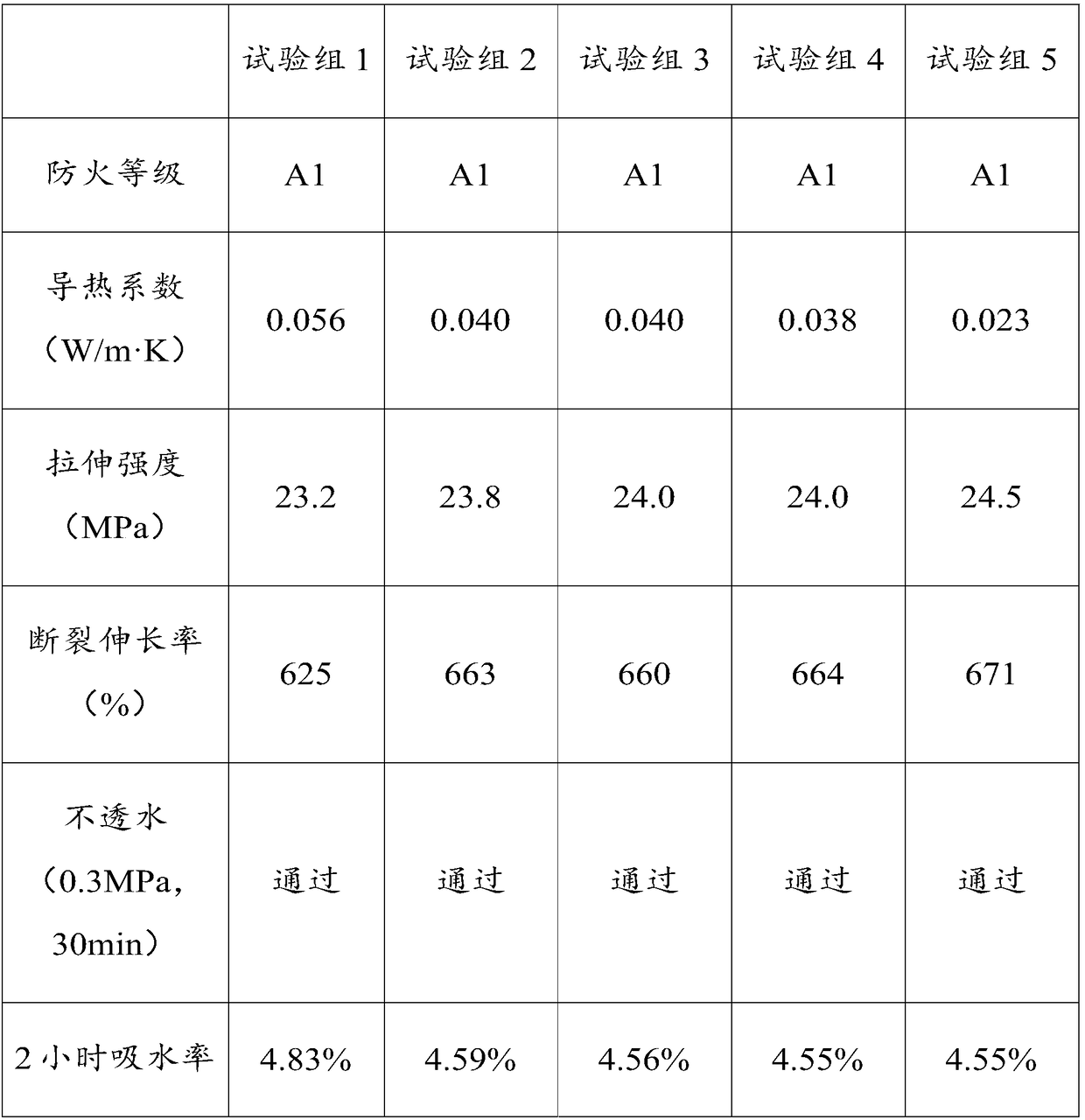

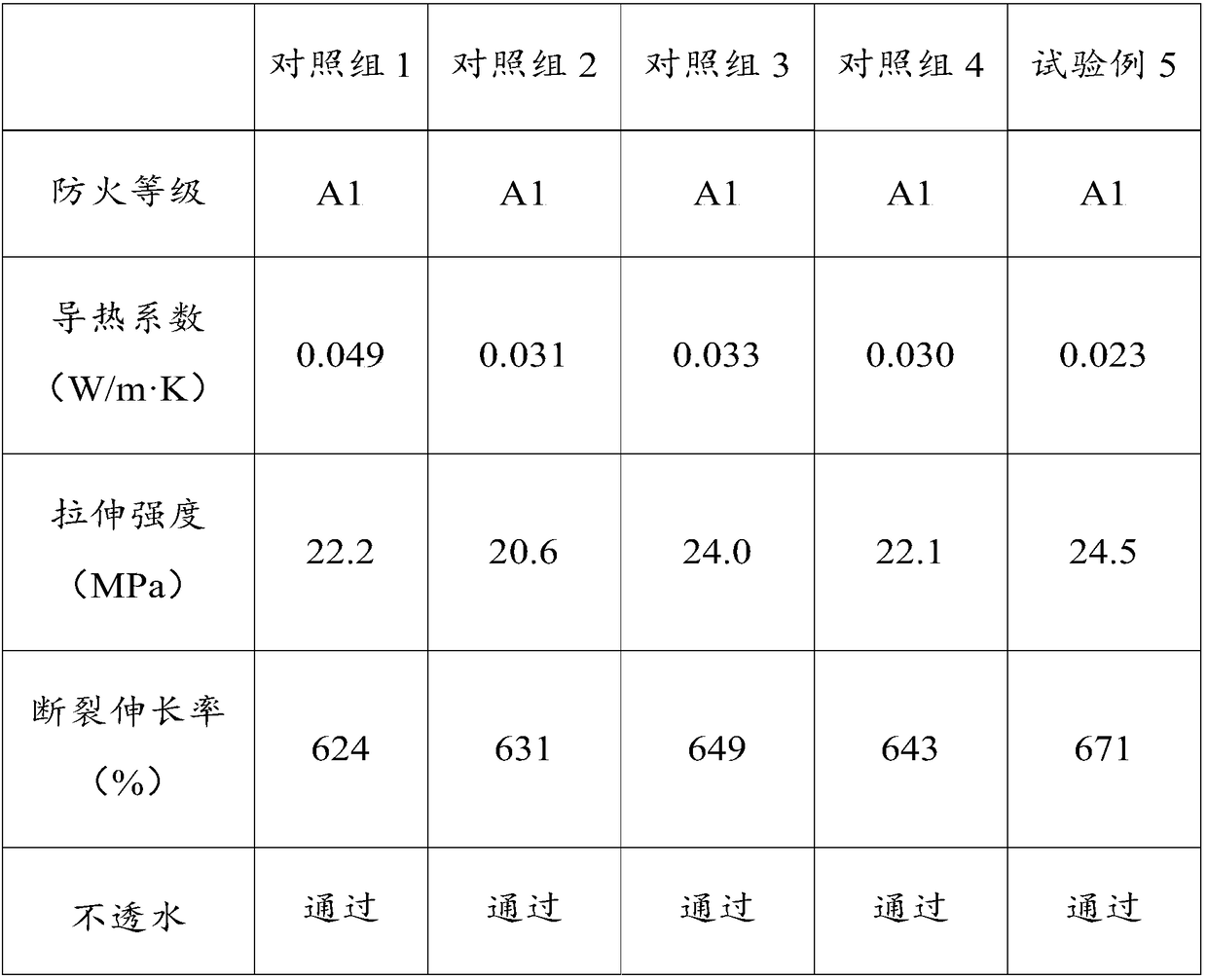

Examples

preparation example Construction

[0033] In addition, an embodiment of the present invention also provides a method for preparing a fireproof, waterproof, and moisture-proof exterior decoration prefabricated wall enclosure material, which may include the following steps: crushing expanded perlite, mixing Portland cement with water, and then crushing Mix the final perlite, Portland cement mixed with water and other raw materials except hardener, heat for the first time, add hardener, and heat for the second time.

[0034]Preferably, the expanded perlite is pulverized to a particle size of no more than 100 μm under the condition of electric pulse frequency of 4000-5000 Hz. After being pulverized by high-pressure pulses, the expanded perlite can be pulverized into fine particles, thereby breaking its original honeycomb structure and reducing the water absorption of the structure. In addition, after the expanded perlite is pulverized, its total expansion volume can be increased compared with that before the pulver...

Embodiment 1

[0041] 15 parts by weight of expanded perlite was pulverized to a particle size of 100 μm under the condition of an electric pulse frequency of 4000 Hz. 20 parts by weight of Portland cement with a volume ratio of 1:1 and a flow rate of 10m 3 / min speed spray into the water.

[0042] The above-mentioned perlite after crushing, Portland cement mixed with water, 10 parts by weight of aluminum silicate fiber, 8 parts by weight of sulfonate flame retardant, and copolymerization of 5 parts by weight of butadiene-styrene The polyanion cellulose of 2 weight parts, the polyester ene fiber of 2 weight parts, the sodium sulfate of 1 weight part, the antifungal agent of 2 weight parts, the modifying agent of 1 weight part and the retarder of 0.5 weight part Mix and heat treat at 180°C for 14h. Then add 2 parts by weight of hardener, heat treatment at 800° C. for 20 hours to obtain fireproof, waterproof and moisture-proof exterior decoration prefabricated wall enclosure materials.

[0...

Embodiment 2

[0045] 20 parts by weight of the expanded perlite was pulverized to a particle size of 50 μm under the condition of an electric pulse frequency of 5000 Hz. 30 parts by weight of Portland cement with a volume ratio of 1:1.2 and a flow rate of 15m 3 / min speed spray into the water.

[0046] The above-mentioned perlite after crushing, Portland cement after mixing with water and 12 parts by weight of aluminum silicate fiber, 12 parts by weight of sulfonate flame retardant, and copolymerization of 8 parts by weight of butadiene-styrene The polyanion cellulose of 4 weight parts, the polyester ene fiber of 4 weight parts, the sodium sulfate of 2 weight parts, the antifungal agent of 3 weight parts, the modifying agent of 2 weight parts and the retarder of 1 weight part Mix and heat-treat for 12 hours at 220°C with a stirring speed of 500r / min. Then add 4 parts by weight of hardener, heat treatment at 1000° C. for 18 hours to obtain fireproof, waterproof and moisture-proof exterior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com