Modified asphalt and asphalt concrete

A technology for modifying asphalt and asphalt, applied in building components, building insulation materials, building structures, etc., can solve problems such as reflection cracks, and achieve the effect of improving service life, strong anti-reflection crack ability, and strong elastic recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

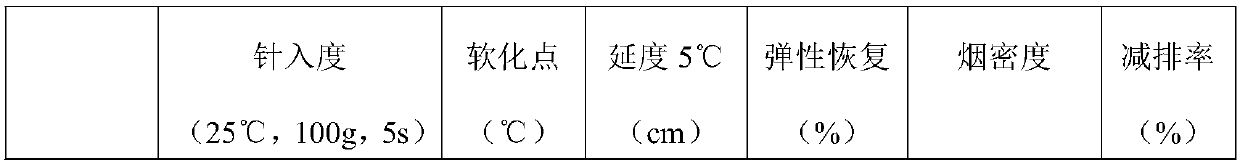

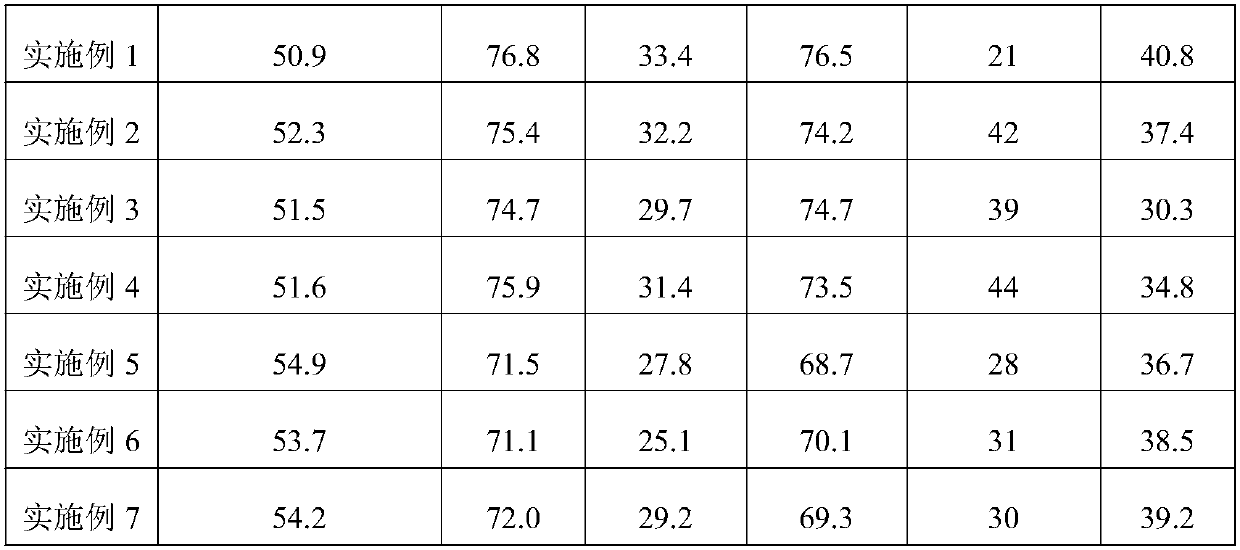

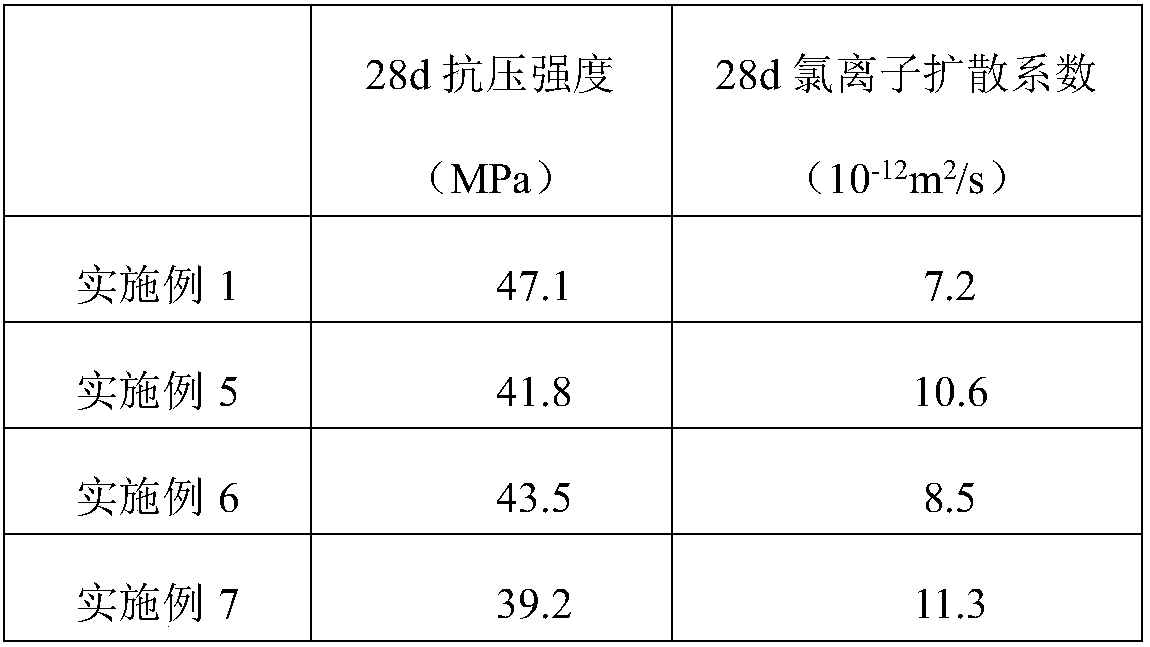

Examples

Embodiment 1

[0032] Modified asphalt raw materials (parts by weight): 100 parts of asphalt, 7 parts of polypropylene, 3 parts of SBS, 0.9 parts of petroleum resin, 1 part of dimethyl phthalate, 3 parts of flame retardant, 0.3 parts of crosslinking agent, sulfur 0.2 parts.

[0033] The flame retardant is obtained by stirring and mixing aluminum hypophosphite, magnesium hypophosphite, and zinc borate in a mass ratio of 1:1:1.

[0034] The cross-linking agent is obtained by stirring and mixing tetramethylthiuram monosulfide, p-tolualdehyde, and terephthalenedimethanol uniformly in a mass ratio of 1:1:1.

[0035] Modified asphalt preparation:

[0036] (1) Put polypropylene, petroleum resin, and dimethyl phthalate in a high-speed mixer, control the speed of the high-speed mixer at 350 rpm at room temperature, mix for 5 minutes, take it out and transfer it to a twin-screw extruder , Extrude and granulate at 160°C, control the speed of the screw machine at 400 rpm, and obtain modified polypropy...

Embodiment 2

[0041] It is basically the same as in Example 1, except that the flame retardant is obtained by stirring and mixing uniformly magnesium hypophosphite and zinc borate at a mass ratio of 1:1.

Embodiment 3

[0043] It is basically the same as in Example 1, except that the flame retardant is obtained by stirring and mixing aluminum hypophosphite and zinc borate in a mass ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com