Drag reducing mud and its preparation and use method

A mud and polyacrylamide technology, applied in chemical instruments and methods, mechanical equipment, pipeline laying and maintenance, etc., can solve the problems of lack of support and drag reduction, poor durability, poor water retention, etc. Torque and operating current of cutter head, excellent durability, and effect of reducing frictional resistance

Active Publication Date: 2020-12-29

SHANGHAI ROAD & BRIDGE (GRP) CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The technical problem solved by the present invention is to overcome the poor water retention, poor supporting performance, poor complete set performance and poor durability of the drag-reducing grout for pipe jacking in the prior art for the cohesive soil layer, which leads to the inability to Form a complete drag-reducing mud sleeve, and thus fail to provide effective support and drag-reducing effects, thereby providing a drag-reducing mud and its preparation and use method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] The material ratio of the used drag reducing mud is bentonite: soda ash: polyacrylamide: water=350kg:5kg:1.2kg:780kg.

[0033] Slurry mixing and grouting process: Use a mixer to mix the above components into a paste-like drag-reducing mud, then manually transport the paste-like drag-reducing mud into the pipeline, and then press it into the grouting hole through a screw pump, and finally inject it into the pipe outside the wall.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses drag reduction slurry, as well as preparation and use methods of same. The drag reduction slurry includes bentonite, an alkaline inorganic substance, polyacrylamide, and wateraccording to mass ratio of bentonite : alkaline inorganic substance : polyacrylamide : water = (290-295):(4-5):1:(645-655), wherein the alkaline inorganic substance is Na2CO3 and / or NaOH. The drag reduction slurry is excellent in water retention property, complete set performance, supporting and protecting performance and endurance, can be used for pipe jacking and shield tunneling and especiallyis suitable for high jacking force. During use, slurry injection frequency is reduced largely, and a slurry sleeve is effectively formed during the jacking process, thereby greatly reducing frictionresistance of outer wall of a pipeline and reducing jacking force during the jacking process, reducing cutter-head torque and working current, and reducing consumption of pipe jacking equipment.

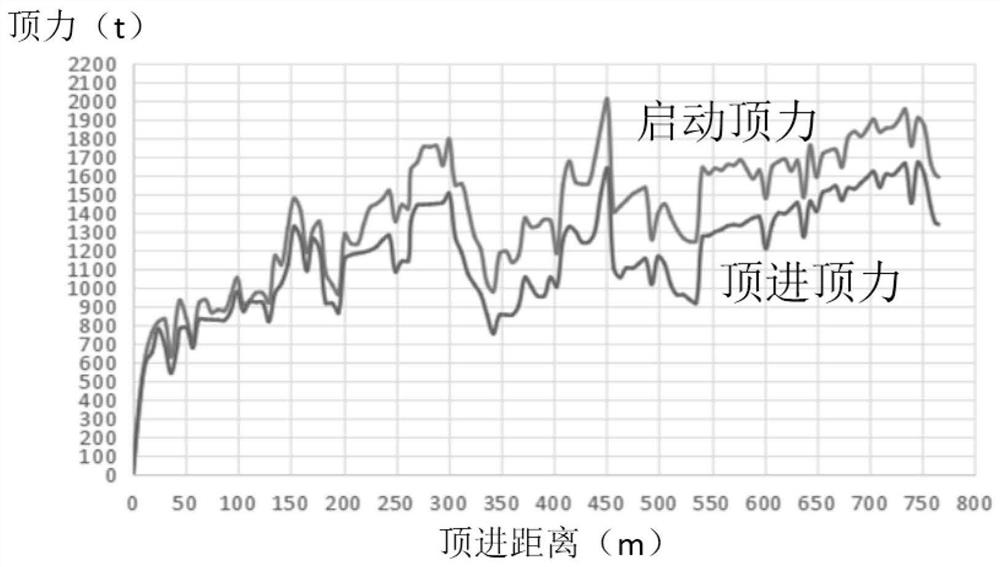

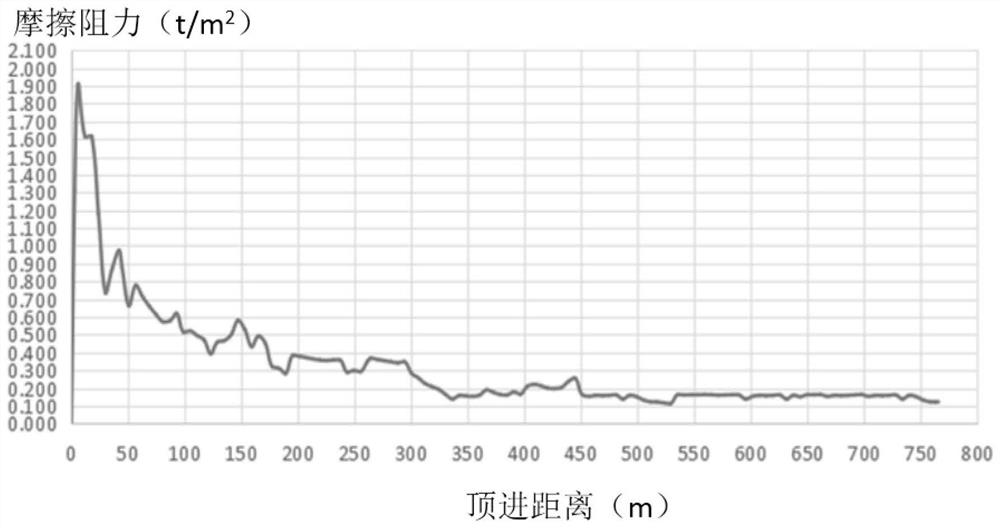

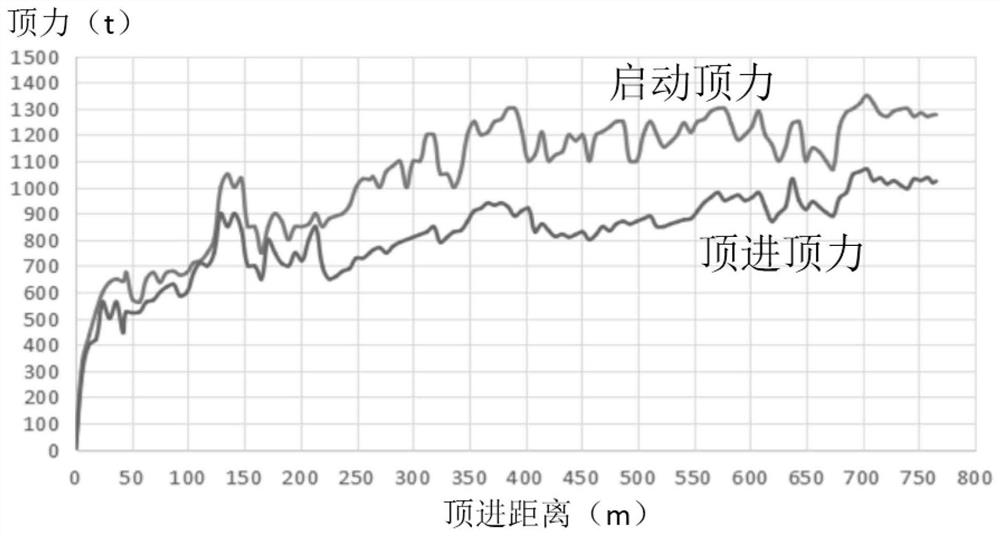

Description

technical field [0001] The invention relates to drag-reducing mud and its preparation and use methods. Background technique [0002] In pipe jacking construction, drag reduction by grouting is a very important link, and it is the key to the success of pipe jacking. During the pipe jacking construction process, if the injected drag reducing mud can form a relatively complete drag reducing mud sleeve on the outer circumference of the pipeline, its drag reducing and supporting functions will receive unexpected results. The formation of an effective drag-reducing mud sleeve can greatly reduce the frictional resistance between the pipe wall and the soil layer, effectively reduce the jacking force, increase the length of one-way jacking, reduce the amount of relays, and also reduce the work The number of wells and receiving wells can effectively reduce the engineering cost. [0003] When the pipe jacking is carried out in the cohesive soil layer, because the soil layer itself is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/24F16L1/028

CPCC09K8/24C09K2208/28C09K2208/34F16L1/028

Inventor 王剑锋徐飞王帅刘廷扣陈睿马敬豹

Owner SHANGHAI ROAD & BRIDGE (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com